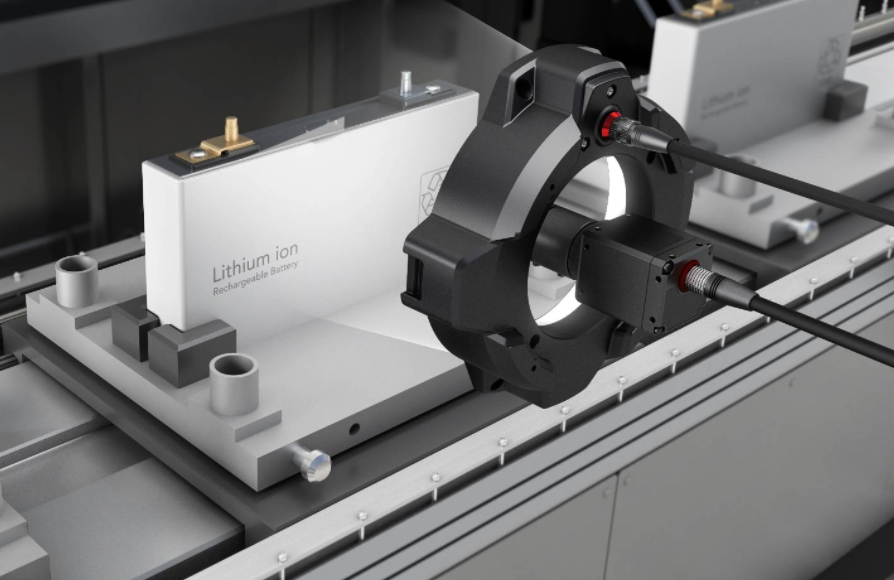

Automated inspection plays a huge role in the manufacturing of electric vehicles. In-line machine vision systems allow manufacturers to ensure that they produce defect-free components at high rates of speed. These systems can also play a pivotal role in the actual assembly of EV components as they often guide robotic arms.

Join this webinar session at our Spring Virtual Conference on EV Engineering, presented by Keyence, to learn how the latest cutting-edge technology in machine vision is used to inspect electric vehicles and their components. Our machine vision expert will show real-world examples of where these advanced technologies are used in the EV assembly process with a focus on batteries, inverters, stators, and robotics.

Other sessions at our Spring Virtual Conference include:

Reduce Battery Dry Room CO₂ Footprint Up To 95%

In this presentation, we will explore how a battery dry room can be optimized with a focus on the adsorption dehumidifier.

Dehumidifiers in Li-ion battery dry rooms use a lot of energy, up to 43% of total energy consumption in the battery manufacturing process, to keep the dry rooms super dry—that’s a relative humidity of under 1% and dew points ranging from -40°C to -120°C.

Rasmus Toftegaard will explain how Cotes adsorption dehumidifiers work, how it benefits manufacturers and how it is possible to achieve massive energy reductions, cost savings, and huge CO₂ emissions reductions.

Register here to learn more—it’s free!

See the full sessions list for the Spring Virtual Conference on EV Engineering here.

Broadcast live April 4 – 7, 2022, the conference content will span the EV engineering supply chain and ecosystem including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.