The future of the EV industry is bright. We’re losing count of all the planned EVs that automakers have in the pipeline. And it seems increasingly likely that they will follow through with those plans.

If there’s one thing everyone agrees on, it’s that all EVs in the near future will have a range of at least 200 miles, or much more. That means battery capacities will continue to grow, and if the average recharge time for DC fast charging is going to keep up (or get shorter), power levels will need to increase substantially as well. Tesla’s Superchargers are currently maxing out at 140 to 150 kW – which is about three times higher than current EVs equipped with a CHAdeMO or Combined Charging System (CCS) plug.

There are a few indications that we’ll soon see systems capable of rates much higher than Tesla’s top charging power.

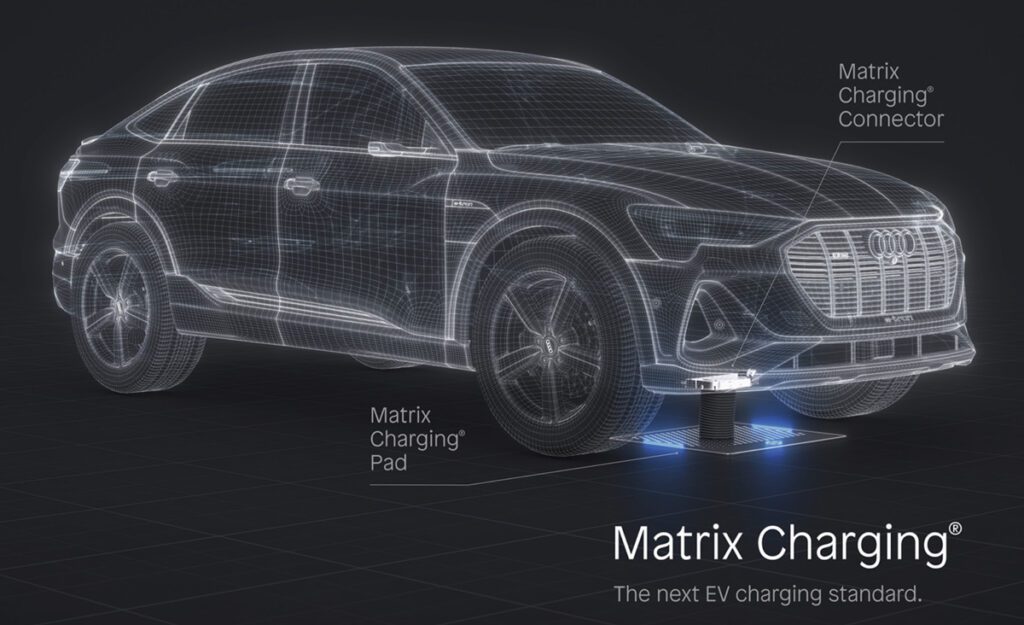

Porsche, for example, has developed an 800-volt charging system (double the voltage of the current CCS standard) for its Mission E concept.

A larger group of Europeans also took a step in this direction last year, with the formation of the Charging Interface Initiative (CharIN). Audi, BMW, Daimler, Opel, Porsche and Volkswagen, together with a couple of charging equipment manufacturers including ABB, are promoting technical standards for CCS, and working to increase its capabilities. CharIN’s immediate goal is to increase the CCS charging level from 50 to 150 kW. Some CharIN members have hinted that, in the longer term, power levels could be increased to as much as 350 kW.

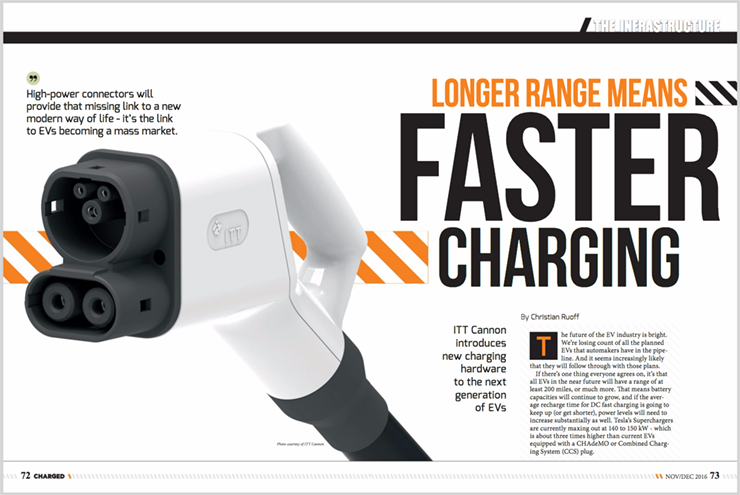

In the race to develop faster charging solutions, global electronics player ITT, through its Cannon brand, introduced a new DC fast charging system in October. Cannon’s Cooled Ultra-Fast DC Charging Solution is a liquid-cooled connector and cable design that enables charging at a level of 400 A at 1,000 V. The company says its high power-density system is capable of delivering the charge required for 60 miles of range within 3 to 5 minutes.

To learn more, we chatted with Ralf Glocker, ITT’s Senior Product Manager for Electric Vehicle Charging.

Charged: What prompted the development of your new liquid-cooled ultra-fast DC charging solution?

Ralf Glocker: About a year ago, we had both EVSE and vehicle manufacturers approaching us and asking for the same thing. We were a bit surprised by the first feedback, asking us for 400 A and 1,000 V. However, these numbers were repeatedly brought up. It was these specific drivers of the market that really prompted the development.

Overall, we identified EV connectors as a strategic market for us, promising sustainable growth in the future. High-power charging in particular is one of the most significant areas, as it aligns with our strategy and way of thinking at ITT. We have it in our DNA to solve the hardest technological challenges.

While most customers asked for a solution in the 350 to 400 A range, we actually designed and tested the system to 500 A. We also think the trend will keep increasing. High-power connectors will provide that missing link to a new modern way of life – it’s the link to EVs becoming a mass market. It’s a core technology, and we strongly feel that this is a key area we want to grow in.

A few years ago we started off our EV charging solutions with high-performance AC connectors but this is our first activity with DC charging.

Charged: Could you explain the details of the liquid cooling circuit?

Ralf Glocker: Most importantly, we’re actually cooling inside the connector itself – with an IP-protected design – as opposed to just cooling the cable. The coolant is flowing through the cable – which allows it to have a very small diameter- and then it’s cooling the contacts to control the temperature at the connection.

This actually allows us to maintain a unique temperature profile. When we charge at full power, the zone with the lowest temperature in the entire assembly is the contact between the car and our connector – even at 350 A or more continuously. Because the cooling is internal to the connector, it’s allowing us to very quickly dissipate the heat. The coolant is going from the intercooler to the cable to the connector, and back again.

Our connector design uses two coil springs per contact for redundancy. This approach creates multiple contact zones and therefore allows us to increase the conductivity, while the internal cooling leads to very little thermal impact from the local current. The design also requires minimal mating forces, which is critical in this domain.

Charged: Would it be possible to reach these high charging powers without liquid cooling?

Ralf Glocker: It could be done, but you would need a very big cable, making it hard to handle and therefore providing a poor experience.

From the beginning, our development partners were focused on a prime handling experience. User operability is core to everything that we’re doing here. Therefore, based on our best-in-class quality pledge, we understood that we could only achieve this with a liquid-cooled solution.

Typically, in the automotive industry, and generally with equipment that will be handled by the public, you need to consider users that are slighter than average. In other words, you can’t simply design something for the person of average size. You need to consider all those who might not have the physical strength of an average person – they need to be able to easily handle the equipment as well. And without liquid cooling, that type of individual could not really cope with the bulky cable and connector.

Liquid cooling allows you to reduce the cable weight by about 40%. As soon as we had decided on this approach, we asked ourselves, how do we want to implement it? There are various options, and we identified that by cooling the connector itself internally, instead of just the cable, we could keep the temperatures as low as possible.

Charged: How soon do you think we will start to see these high-power charging solutions in use with production vehicles?

Ralf Glocker: We’ve already supplied first customers with trial versions for tests. So we’re past the initial R&D stage, and we are actually testing products out in the field.

The issue, of course, is that the final standard for higher-power charging is not yet reviewed or approved. But we recognized, particularly in the European auto industry, that there is a strong market force applied to charging speed – everybody wants to have high-power charging. And we think it will move quickly.

While we have been producing smaller volumes already this year, we expect to have commercial availability next year. Since there are so many variants customers are asking for, both on the EVSE and automotive side, and because standards are not fully defined yet, commercial availability might vary, depending on different customer approaches. We are seeing a really strong customer push for this product. It’s an exciting time for us and we’re gaining some great field experience now.