Q&A with Mack Trucks’ Scott Barraclough

Most followers of tech trends probably think of electric vehicles as luxury performance cars, but here at Charged, we get just as excited about commercial vehicles. As regular readers know, the electrification of trucks and other heavy-duty vehicles is quickly picking up, driven by both regulation and technological developments.

Speaking of picking up, garbage trucks may be the least glamorous of vehicles, but we all rely on them, and they turn out to be excellent candidates for electrification, given their typically short routes and stop/start duty cycles. Mack Trucks has been building refuse vehicles for decades, so it’s no surprise to find that the company is now building an electric refuse truck.

Mack’s first foray into electrification was in the 2000s, when it built a couple of diesel hybrid garbage trucks. The vehicles worked well, but the costs were high at that time, and the company decided that the technology wasn’t mature enough for full commercialization. A few years ago, finding that EV tech had advanced, Mack decided to build an electric truck for a long-time customer, the New York City Department of Sanitation. A prototype and a testing program followed, and Mack is now in production with the LR Electric truck (the name means “Low-entry Refuse”).

Scott Barraclough has been with Mack Trucks for over 20 years now, primarily on the powertrain side, and has been working on e-mobility for the last 5 years. He’s been involved with the development of the Mack LR Electric almost from the start of the program. He recently spoke with Charged about Mack’s electrification push.

Charged: Tell us about some of the refuse vehicles you have out there. Are there any customers or case studies you can talk about?

Scott Barraclough: We’ve been running tests since 2020. The City of New York and Republic Services have been the ones running the trucks the longest. New York has seven of them online already, or coming online very shortly. Republic has a couple running as well. Operationally, they work very well. They’ve been very pleased with them.

The drivers really love them. From an operator perspective, they’re great. They’re very quiet.

The drivers really love them. From an operator perspective, they’re great. They’re very quiet. You don’t have a diesel engine, so they’re much quieter and more comfortable for the operator. If you think about that, in a refuse truck, if you’re sitting in the driver’s seat, the diesel engine is essentially under your right arm.

As with any electric vehicle, the challenge has been range. In New York City, it really hasn’t been their routes. If you think about New York, it’s all in a very dense area. There’s not a lot of distance to be covered. But when you start getting out into suburban routes, there are a lot of routes where electric trucks fit very well, but not all of them. And we know that, so what becomes important is identifying the routes where the truck will work and then assigning the truck to those routes.

Charged: What is a typical range for a garbage truck’s route?

Scott Barraclough: That’s a big “it depends,” because every route’s different. It depends on climate, topography, driver habits. When you look at a refuse truck, they are more often than not in residential collection, and it’s not just driving from A to B—you’ve got to stop 500 to 700 times in the middle to pick up a can of trash. Again, it really depends, but in the neighborhood of between 70 and 100 miles.

The bodies which include trash compactors run off a power takeoff on the truck. It’s the same hydraulic body in most cases that you have on a diesel truck. That consumes power, and if the body’s using power, you can’t use that to drive the truck, so you have to take that into account as well. But there are electric bodies out there that bring their own power. That can extend your range by 20%, 30%.

You’ve got to stop 500 to 700 times in the middle to pick up a can of trash. Route length really depends, but in the neighborhood of between 70 and 100 miles.

Charged: Is there variation in the payload or what’s collected?

Scott Barraclough: It can vary, and that certainly is a factor when it comes to range, because the heavier the vehicle, the more energy it takes to move it. We started looking at recycling. It’s generally quite a bit lighter than general trash. So, it depends on the route they’re putting it on.

Charged: The LR Electric chassis has a 376 kWh battery pack. That’s very big.

Scott Barraclough: Well, it all depends on what you’re comparing it to. There’s nothing even close to that on the passenger car side, but your passenger cars are not rated at 66,000 pounds either.

Charged: What is the main driver for a city to put these trucks in their fleet? Is it state and local incentives, is it that a municipality is really interested in the technology, or are there regulations coming down the line that you think will drive EV adoption?

Scott Barraclough: I would say all of the above. Yes, there are incentives out there, and almost all of our customers when they are getting into the LR Electric are using incentives of some kind. Also, depending on where you’re operating, there will be mandates coming in some areas, namely West Coast, California, Washington, Oregon, where fleets of a certain size will be required to have electric vehicles. Customers are wanting to get a little bit ahead of the game there and get experience with them. And then, there are also municipalities and other companies out there that are very [forward-thinking] and have a green mindset, and electric vehicles fit very well with that. So, I would say all three of those are factors for customers considering electric vehicles.

Charged: You also have a medium-duty electric truck in the pipeline. What sort of target markets do you think that that’ll be a good fit for?

Scott Barraclough:Yes, the new MD Electric will be coming to production late this year. The medium-duty is a different animal than your heavy-duty trucks, but we see a lot of general freight box trucks, flatbeds, stake trucks, refrigerated units, even getting into some smaller dumps. We can’t go too big with a dump because it has more of a lightweight chassis, but smaller dumps for municipal or landscaping usage, things like that. It’s a pretty adaptable chassis. It can be used in a lot of different applications.

We have two options available for the battery pack on the MD Electric, a 150 kWh pack and a 240 kWh pack.

We see a lot of general freight box trucks, flatbeds, stake trucks, refrigerated units, even getting into some smaller dumps.

Charged: So, you sell the chassis as is and then third-party upfitters build the other systems on them?

Scott Barraclough: That’s correct. We provide the chassis and then a body company will install whatever body the customer needs. It’s the same with the refuse truck—we build the chassis and then there are refuse body companies out there that will install the body onto the chassis.

Charged: I imagine the electric trucks deliver a substantial amount of savings on fuel and maintenance. Do you have an idea of what the total cost of ownership is versus diesel, or what the payback period is?

Scott Barraclough: Again, that’s going to vary, on both the MD and the LR Electric. Both are different in that respect. On the LR Electric side, we can do a total cost of ownership analysis, but to start making a reasonable business case, incentives need to be involved at this point in time. And they have been. They’re out there. We’ve seen our customers taking advantage of incentives that are available.

Charged: The LR Electric has two-stage regenerative braking. Can you explain how that works?

Scott Barraclough: Yes. The LR Electric and the MD Electric are a little bit different in their operation, but for the LR Electric, you can have it in Low or High mode, which controls the amount of retardation that you get and how quickly it slows the vehicle. In High mode, when you take your foot off the throttle pedal, the regenerative braking kicks in. That’s the setting that you want to use going house to house—as soon as you take your foot off the throttle, it slows down. [Editor’s note: This is what some EV makers call “one-pedal driving.”]

We also have an automatic setting which blends the regenerative braking in with the brake pedal. So just taking your foot off the throttle is not enough to instigate the regenerative braking. You’d want to use that when you’re driving back to the landfill or back to home base. Because as you’re driving down the road, once you get up to speed, you may want to take your foot off the throttle and just coast to maintain speed in traffic, but you don’t necessarily want to slow down.

Again, these are a little bit different than cars as far as how they operate, on the refuse side. The medium-duty side is much more like a passenger vehicle as far as the way it operates.

Charged: That reminds me of a report I read a few months back about a delivery truck application. One of the surprising reports from the electric truck drivers is that they found it very nice not to have to slam on the brake every time in stop-and-go applications. It’s something I didn’t really consider, but I imagine that’s a huge driver incentive.

Scott Barraclough: Oh, yeah. It takes a little driver education and it takes a while to get used to, because it’s different than what you’ve had on a combustion-powered car, but once you get used to it and figure out how to work it, it works very well. On refuse trucks especially, if you think about it, they’re going house to house 600, 700 times a day. They eat brakes, as you might imagine. The regenerative braking is going to help with the operating costs there, significantly improving brake life on the vehicles.

When going house to house 600, 700 times a day…they eat brakes, as you might imagine. The regenerative braking is going to help with the operating costs there, significantly improving brake life on the vehicles.

Charged: You also have a vehicle-as-a-service offering, like a leasing system. But can you talk to us about your infrastructure-as-a-service program and what that provides for fleet buyers?

Scott Barraclough: The fleet buyers work with our Mack financial folks. We help them get their infrastructure installed and up and running at their facility, and work that into a fixed payment, similar to the way they would with the vehicle-as-a-service program.

Charged: More and more companies are telling us that, as they go from a single vehicle to multiple vehicles, the charging complications really compound for fleet facility managers.

Scott Barraclough: For anyone considering a heavy-duty electric vehicle, as soon as you start thinking about the truck, you really need to be thinking about the charging as well. Because in many cases, you may be able to acquire a truck before your facility would be ready to charge it, and they need to be happening simultaneously. You want to have your charger up and running before the truck shows up. Because if it goes the other way, you’re not operating the truck.

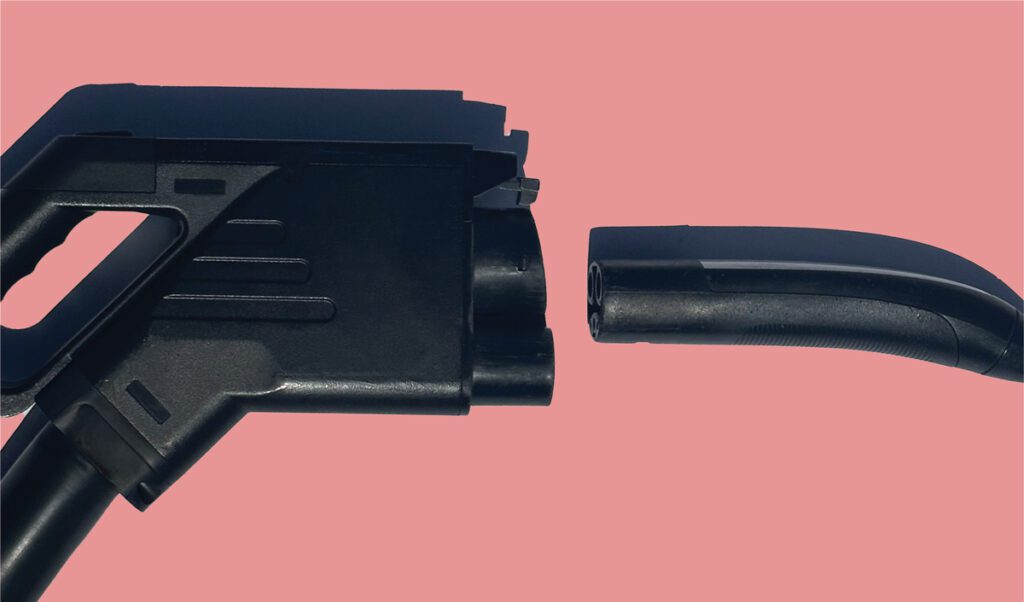

Getting charging infrastructure set up depends on the facility—some facilities have the power needed already there, and it’s not a major undertaking. Other facilities don’t. The utilities need to become involved, and that all takes time. That all needs to be done before the truck shows up. So, infrastructure’s an extremely important part of the equation, and frankly, you probably should be thinking about the infrastructure before the truck. You can’t take these [trucks] and plug them into the wall.

Charged: Can you tell me a bit about the charging capabilities of both trucks?

Scott Barraclough: On the LR Electric, it is DC fast charging only. That’s about the only way that’s really practical for that vehicle’s pack of 376 kWh. You need to be charging at a high rate, even if you’re going to be charging overnight, which most of our customers are going to do. They’ll run their shift during the day, plug it in at the end of the shift. The LR Electric has a much bigger pack on there too, so you can charge at a higher rate, up to 150 kW.

On the MD Electric, it will do DC fast charging up to an 80 kW rate, as well as Level 2 charging up to 19.2 kW.

Charged: But I would imagine that’s predominantly overnight charging as well, right?

Scott Barraclough: Yes. Our customers made it very clear that they would prefer to run their trucks all day without having to charge, or a full shift without having to charge. So, they will charge overnight and then run the trucks for the shift, and then charge again overnight for the next route, or the next day. Typically, our customers are getting the 50- to 80-kilowatt chargers, and that’s more than sufficient to charge overnight.

This article appeared in Issue 65: July-September 2023 – Subscribe now.