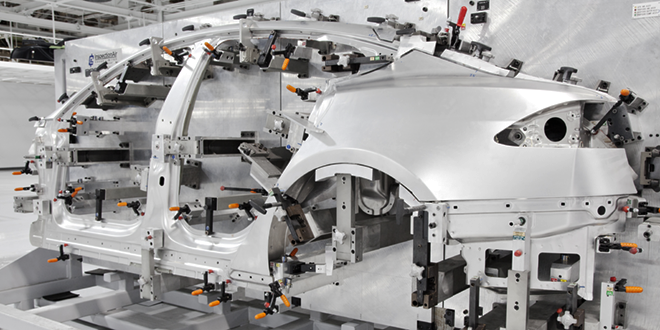

For years, automakers have been steadily outsourcing more and more of their manufacturing. Modern vehicles are assembled from parts made by suppliers all over the world, and in some cases, even the final assembly is done under contract by companies such as Magna and Valmet.

Tesla has reversed this trend to a certain extent – its enormous Fremont factory has a “secret” second floor where the company builds many of its battery, power electronics, and drivetrain systems. Tesla even builds some of its own seats, a complex undertaking that other major automakers would consider madness.

In a recent Wired article, Greg Reichow, who was Tesla’s VP of Production during the historic transition from low-volume Roadster production to the highly automated assembly of Models S and X, describes the company as “more vertically integrated than any car company since the heyday of the Ford Rouge plant in the late 1920s.”

That wasn’t the original idea. As Marc Tarpenning told me in 2013, when he and Martin Eberhard started working on an electric car, they were confident that they could make the drivetrain themselves. “That’s Silicon Valley stuff – computers and batteries.” However, the only way the startup would be able to build an actual car would be to buy most of the other components from suppliers.

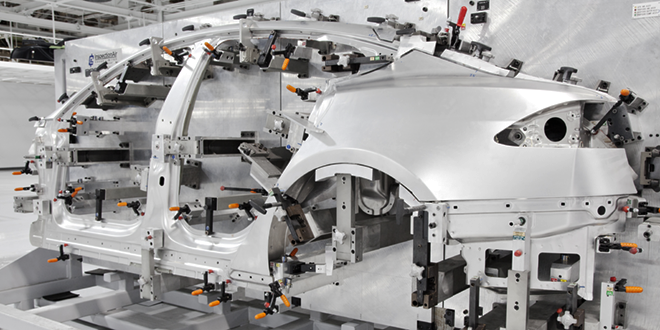

Once Tesla had demonstrated with the Roadster that it could build an EV that people wanted to buy, its ambitions grew. The goal became to build the best cars in the world. As Reichow explains, Tesla needed technologies that were not readily available, and it needed to move at Silicon Valley speed, which would seem crazy to most automotive suppliers.

Building its own core components allowed Tesla to make choices quickly. “Launching a new product presents a team with thousands of small decisions,” Reichow writes. “Nothing beats the ability to have the full engineering team walk into the manufacturing area every day, talk to the people building the products, and gain insights on how to improve. Despite what many contract manufacturers promise, the reality of outsourced manufacturing is that you are getting on an airplane to solve problems you could otherwise solve by walking across your building.”

Building components in-house allows for faster cycles of learning and improvement. “The idea of bundling improvements and building them into the next platform every three to four years (the typical development cycle for the car industry) made absolutely no sense to us at Tesla,” Reichow writes. “Our approach at Tesla was to adopt improvements as soon as they were ready. This meant we were implementing up to 50 changes per week.”

By building components in-house, Tesla gained a deep understanding of its products and how to improve them. As an example, Reichow describes the innovation that enabled Tesla to create Ludicrous Mode. “One of the constraints in increasing the power output of the battery in the early Model S was the safety fuse and switch system that was integrated into the pack. A fuse? How hard could it be to find a fuse that enables the increased current levels needed for this performance? It turns out that it is really hard to build a fuse that allows a massive amount of current to flow during normal operation while also protecting the car in milliseconds if there’s an abnormal spike in current flow. Building fuses in-house helped us solve this problem.”

Source: Wired