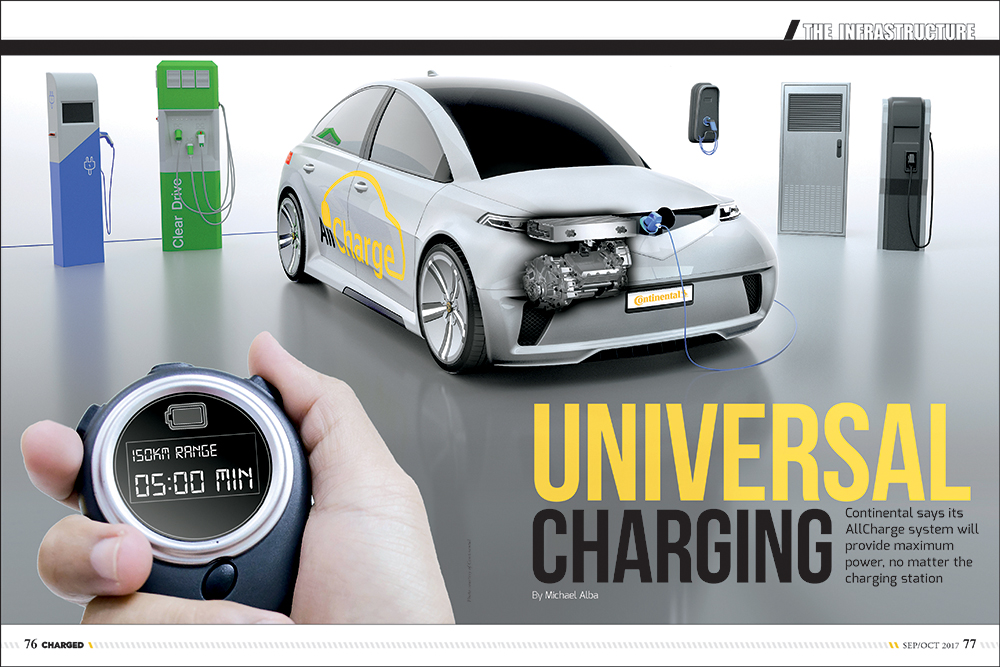

Continental’s AllCharge is a technology that aims to provide a universal charging experience for EVs. The way it sets out to do this is simple, yet surprisingly unique: Instead of using purpose-built charging components, AllCharge makes use of the existing components of an EV’s electric powertrain to charge the vehicle.

“Normally you have to swallow a bitter pill,” says Dr. Oliver Maiwald, Head of Powertrain Technology & Innovation at Continental. “When producing an electric vehicle, you have to define the main charging system, and maybe some optional charging systems.” The charging systems you define for your EV correspond to the three types of charging stations found in the wild: single-phase AC, three-phase AC, and DC. AC chargers are cheaper to build, but DC chargers offer the quickest charge.

The bitter pill in this scenario is that some EVs will be incompatible with some types of charging, and even if an EV is compatible, it may not be able to charge at the maximum power available at the site. This could result in some frustratingly slow charging times. “For instance,” explains Maiwald, “in Germany, it takes some time, if you want to charge in your household power or plug socket with three kilowatts.”

A better way to charge

One way to address these problems would be to build some type of charging adapter – an EV dongle, if you will. “An easy option would be to install a monster charging device handling all these different charging types,” says Maiwald. “But this is incredibly expensive, because it’s an on-top device.”

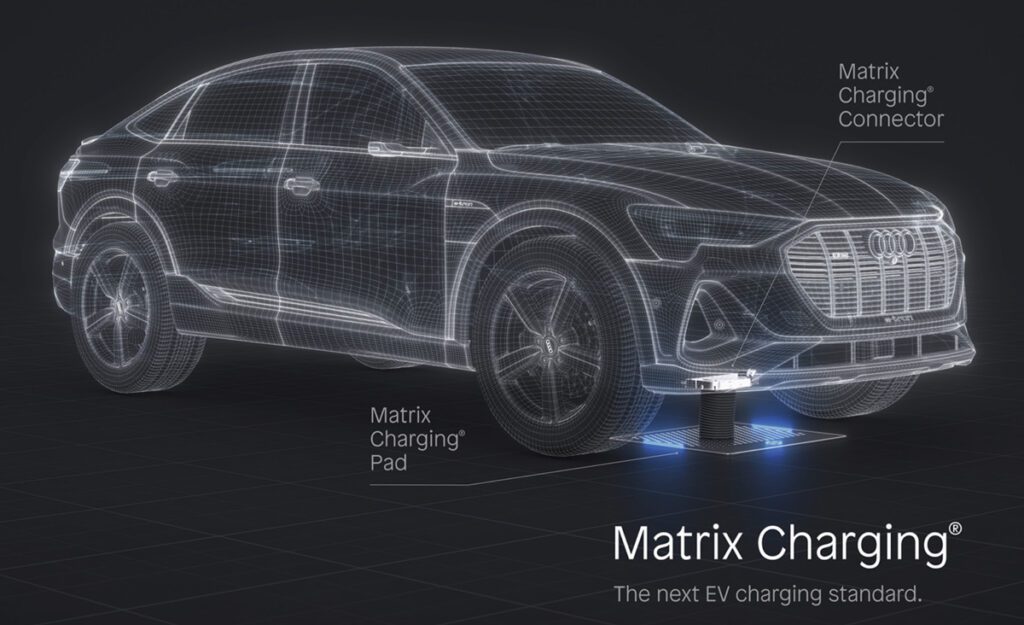

A better solution hinges on recognizing a simple fact: The functionality needed for EV charging is already present in the EV’s electric powertrain. The powertrain’s inverter is used to switch between AC and DC at different voltages, which is exactly what’s needed to charge an EV battery. So why not let it?

“One of the biggest success stories of AllCharge was to put the charging guys and the driveline guys and the battery guys in one room,” says Maiwald, “to really figure out what can be used in terms of the components in common, and what components might be needed for a certain purpose.”

This multi-disciplinary approach allowed the AllCharge team to design a charging solution with minimal modifications to the existing powertrain electronics. In fact, the only additional component in the system is a DC-DC converter, used to ensure optimal power flow to the battery. Apart from that, the increased usage of the powertrain components simply requires more durable electronics.

“Of course, there are some minor changes in the system, which create some additional costs,” says Maiwald. “The complete system has to be slightly more robust for this higher usage. But we have to compare the overall system costs in the end. And here we definitely see a competitive advantage compared to the different devices you have to integrate, when you want to go to higher charging powers and [shorter] charging times.”

The comparative simplicity of AllCharge belies its numerous advantages. First, AllCharge is compatible with all three types of charging stations – single-phase AC, three-phase AC, and DC. Furthermore, AllCharge will always allow for the maximum charging power, with an output rate of up to 800 V and 350 kW.

“The main idea was to always have the maximum charging power, no matter which charging station you want to plug into,” explains Maiwald. “And this is one of the benefits for the car manufacturers. Plus, with AllCharge, they understand you have a really high flexibility, in terms of being well prepared when DC charging stations will pop up on highways or at shops in a massive way. The car is already ready to do DC charging without any additional components – so, it’s really ready for the future.”

Another perk of the AllCharge system is that it will enable drivers to access 230 V of AC power for personal use. This means that your EV battery could be used to power anything from your phone to your laptop, electric power tools, or even a refrigerator.

The future of AllCharge

So when will you get to see it in your EV? Although Continental has been working on AllCharge for two years, the system is still in the prototype phase.

“We have a running system now, and we’re doing more and more functions,” says Maiwald. “We’re testing high-powered charging in our R&D center in order to evaluate the different charging types in different scenarios. We plan to go into production for the next car generation. This is our target.”

Though it may seem a long time until the early 2020s, Maiwald expects that AllCharge will be ready for whatever charging technology might emerge in that time. “With AllCharge, you have the systems already available in your drivetrain, so we do not see that there are any limitations. Not now, and also not in the future – because AllCharge, at least from what we know so far, is able to operate with any charging power and systems we foresee for the future as well.”

The next steps for AllCharge are to make it bullet-proof, according to Maiwald. This involves validating its capabilities. However, despite the work that still needs to be done, Maiwald says there’s already interest from automakers.

“Unfortunately, or luckily really, we generated a lot of interest in the market,” jokes Maiwald. “Which is good, but on the other side, the team is now under pressure. There’s definitely a huge interest.”

This article originally appeared in Charged Issue 33 – September/October 2017 – Subscribe now.