Sometimes kids can’t wait to be grown-ups, but growth takes time. An acorn doesn’t become an oak tree overnight. Electric vehicles are a growth industry, and many people in that industry would like to see explosive expansion, rather than the slow and steady gains that have characterized the market for years. Yet even slow progress has a habit of creeping up and surprising you. When you’re walking up a mountain, the peak may seem far out of reach, but look back and you’ll be amazed how far up you are.

For Motiv Power Systems of Foster City, California, the top of the mountain is still a distant goal, yet the company has grown by leaps and bounds. It’s been six years since Motiv CEO Jim Castelaz took a leave of absence from his Stanford electrical engineering Ph.D. program to found his electric powertrain company. “I’m actually still on that leave of absence,” Castelaz told Charged. “I got the entrepreneurship bug, and our initial mission was to free trucks and buses from fossil fuel. That’s what we’ve spent the last six years doing.”

It’s easy now to forget just how dire the economic outlook was in 2009 when Castelaz started Motiv out of his living room as an engineering consultancy for new EV development. It was a time of mass layoffs and general despair after the 2008 crash. Yet Castelaz soon saw a niche opportunity in the market. “As we were working in the heavier vehicle space, we realized every application is different, and heavy vehicles are a very fractured business,” he said. “There’s a little bit of reinventing the wheel with every vehicle type, and the opportunity I saw was to build an operating system for heavy electric vehicles that can easily integrate many different configurations of batteries, electric motors and accessories. By providing the software and controllers, we make it easy for truck builders – who are very good at mechanical integration onto truck chassis – to have the support they need to make electric versions with our operating system.”

That operating system is at the heart of Motiv’s All-Electric Powertrain, which combines commercially available battery packs and motors with Motiv’s software and controllers to make all-electric trucks and buses with the same chassis and bodies as the fossil-fueled versions. These all-electric trucks and buses are ideal for fleet vehicles such as box trucks, flat-bed trucks, refrigerated trucks, service trucks, shuttle buses, school buses, delivery vehicles and garbage trucks.

“Like on a computer when you plug in a new keyboard or printer, you need a software driver, and all that software resides on a common administrative layer,” Castelaz said. “On a vehicle like a school bus, we have the drive motor that drives the wheels, and the air conditioning and heating system; we have hydraulics for steering and braking, and we have to keep the 12 V battery charged for all the smaller accessories. Then we have 4-6 different battery packs on the vehicle, so it’s different from my Nissan LEAF. In the truck world, everything’s built on frame rails, so usually there are multiple smaller battery packs, which is good for configuration and allows you to put just the amount of energy storage per vehicle that’s needed. But that means there needs to be coordinated control of the different batteries, motors and chargers. There ends up being a lot of power sources and power loads on the vehicle that all need to be coordinated. Each one is typically made by a different company, so it’s up to our operating system to make all these disparate components work and play nice together.”

Revving up

Motiv estimates that about one third of the eight million diesel trucks and buses in the US are ideal for electrification, because they drive planned routes of less than 100 miles a day and park in depots at night that are wired for high voltage. So far, the number of those vehicles on the road with Motiv’s All-Electric Powertrain is seven. They have more vehicles currently in the works (about a dozen according to Castelaz) than on the road; in fact, at press time Motiv had more job postings on its website than vehicles on the road, and that speaks to the early growth stage that Motiv still occupies.

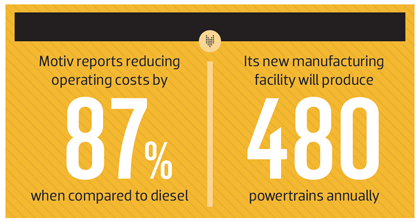

The journey of 1,000 miles begins with a single step. Motiv has taken several steps already, and with its building momentum, it could soon be off to the races. Several important company milestones have been reached with the help of grants from the California Energy Commission (CEC), which recently awarded funds to develop a Class C electric school bus and new generation of electric garbage trucks. This builds upon Motiv’s first All-Electric school bus, which hit the road in California’s Central Valley, and their All-Electric garbage truck deployed in Chicago. Both were the first all-electric vehicles of their kinds in North America, and so far, Motiv reports that these zero-emission vehicles show reduced operating costs of up to 87% compared to diesel vehicles.

Launching the ePCS was also enough to turn heads at Popular Science, which bestowed on Motiv one of its Best of What’s New Awards in 2014.

This year, Motiv’s progress has snowballed. In January, four Motiv-powered electric shuttle buses began servicing Mountain View, California residents in a two-year pilot project funded in part by Google and the CEC, which to date has made over 40,000 passenger-trips. In March, Motiv announced a new chassis option for its electric powertrain, the Ford F59 commercial stripped chassis, with a range of up to 100 miles at a GVWR of 22,000 pounds. It is Motiv’s third chassis option, and it came with an order for ten walk-in vans for the 126-year-old linen and uniform company AmeriPride in Vernon, California.

At the end of May, Motiv opened its new manufacturing facility in Hayward, California, just across the San Francisco Bay from its headquarters. When it reaches full capacity, the facility will be able to produce 480 all-electric powertrains annually. Motiv now builds all of its smaller electronics – battery controllers, motor controllers, powertrain controllers, chargers and accessory drives – in Hayward, and then ships them to a subcontractor in the Midwest to install them onto vehicle chassis. The Hayward facility was partially funded by another $2.2 million in grant funding from the CEC.

Heavy sales duties

Now that Motiv has established a track record and a production plant, it can get down to the business of satisfying what Castelaz says is growing demand for electric trucks in markets with good government incentives for them, including California, New York and the Chicago area. “Incentives are critical today, because they bring the payback period for going electric down substantially,” Castelaz said. “There is a lot of demand for these vehicles, both from fleets who are interested in sustainability and saving money, and from a lot of other stakeholders who like the idea of emissions reduction around sensitive populations, like school kids.”

Motiv seeks out end-user fleets that may be interested in electric trucks and buses, and works with them to specify and configure what they would need in such vehicles. However, the fleets aren’t technically Motiv’s customers. If the fleet operator makes a purchase, it will purchase from a final vehicle builder, such as Trans Tech Bus in New York, who then purchases the All-Electric Powertrains from Motiv for assembly in the final vehicle. Motiv currently has five final vehicle builder partners in its network. It’s open to adding more, but also tries to maximize its existing partnerships, just as it has to get the most out of its three current chassis models.

In addition to the Class 6 Ford F59 chassis that it added in March, Motiv has powertrain kits for the Class 4 Ford E450 cutaway chassis and the Class 8 heavy-duty Crane Carrier COE2 chassis. Castelaz said Motiv currently won’t add more than about one chassis type per year, because it’s quite labor-intensive to do so. “Even though it’s not difficult engineering, each chassis has slightly different dimensions and requires new mounting brackets and new cables – a lot of new parts,” he said.

Motiv hasn’t done the packaging study for a full-size school bus chassis yet, but Castelaz thinks that it could be in Motiv’s future. “Large school buses could be a good fit for electric, and having these smaller school buses lets us get a lot of data about how the buses are used and how school districts think about their vehicles, which will be useful in the future when we do partner up with a larger school bus builder.”

The data collection Castelaz mentioned is a big part of the remote telematics built into Motiv’s system. The company uses it to retrieve a variety of data from the vehicles. The data sets are useful for maintenance and also for reconfigurations by pushing data and/or software updates back onto the vehicle. “We can remotely log into the vehicle to run diagnostic tests to figure out what’s wrong, which saves time and reduces vehicle downtime,” Castelaz said. Specific things Motiv can do remotely include adjusting for more or less regenerative braking, making the acceleration more or less aggressive, etc.

Juiced up for junk collection

Every Motiv-powered vehicle also works with the Motiv Universal Fast Charger. This proprietary creation offers higher power than a standard Level 2 charger, but is not as expensive as a DC fast charging station. It uses three-phase power rather than single-phase, and “that allows us to go from your standard 6 kW Level 2 charge up to 25 kW,” Castelaz said. “It still uses Level 2 protocols, but using three-phase charging, you get kind of the same amount of power you would with a DC fast charger. It’s a $3,000 station, instead of a $30,000-50,000 fast charger. We can work with whatever power is at your facility, whether 208 V or 440 V, and we can get reasonably fast charge rates with minimal infrastructure costs. That’s a big value add for fleet operators.”

Motiv’s garbage truck, or what it calls its electric refuse vehicle (ERV), uses the company’s largest chassis, the Class 8 Crane Carrier. It has 212 kWh of energy in 10 battery packs and a range of 60 miles with a payload capacity of 9 tons, which makes it capable of being used anywhere in Chicago. With Motiv’s Universal Fast Charger at three-phase 440 V, it can charge at up to 50 kW and be fully charged in 8 hours.

For those reasons and more, Castelaz sees enormous upside to electric garbage trucks. Particularly, the Motiv ERV has returned operating costs of about a tenth of those of a diesel truck; it meets the gross vehicle weight rating (at least for Chicago) and it reduces maintenance costs substantially.

“You really have no fluids to change, and even brake wear is substantially reduced,” he said. “You have no exhaust system to worry about, so you have a better experience for the drivers and sanitation workers being next to that engine all day. And if it delivers trash to a waste-to-energy power plant, one truckload of trash produces enough electricity to power that truck for 40 days. That means you have a system that’s net energy producing. It looks very similar to Chicago’s other 600 garbage trucks that drive by your house at 6 am and wake you up sitting there with their idling engines, except that ours is completely quiet and doesn’t have a smokestack or a fuel tank on its side. Instead it has batteries behind the cab.”

This article originally appeared in Charged Issue 20 – July/August 2015. Subscribe now!