Torque vectoring technology is generally defined as a vehicle’s ability to vary the power to each wheel. Quickly controlling the torque applied to the wheels independently of one another allows the driving characteristics of a vehicle to be improved in significant ways – more stability, more responsiveness and more agility.

A conventional differential distributes the driving power equally to each wheel. Whether the vehicle is rear- or front-wheel-drive, there is basically a 50/50 torque distribution, meaning that the wheel with the lowest traction defines the total traction of the car. Technologies like limited-slip differentials and traction control systems help to overcome major problems on slippery surfaces like ice, but they do not add all the drivability benefits available with full torque vectoring systems.

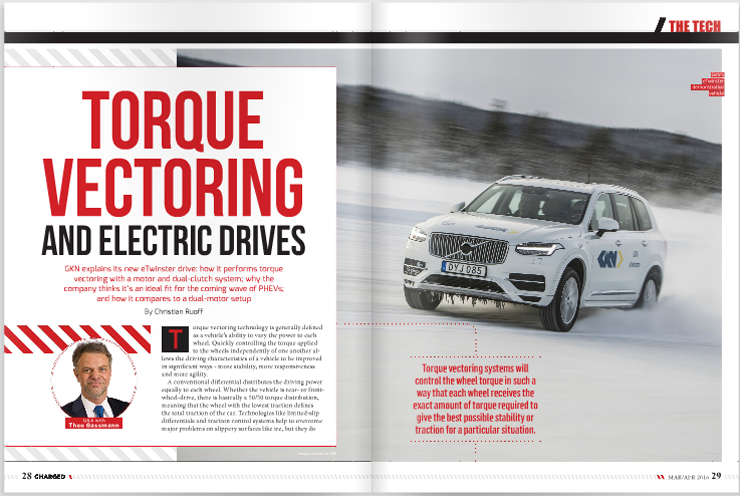

By actually redistributing the torque during normal driving – independent of the slip condition or position of the wheel – torque vectoring technology can create advanced “yaw moments” to respond to all of a vehicle’s inputs. The system will control the wheel torque in such a way that each wheel receives the exact amount of torque required to give the best possible stability or traction for a particular situation.

For example, while steering around a corner, torque vectoring allows you to apply more torque to the outside wheels, which helps to push the car into the corner – a reaction known as oversteering. Similarly, by providing more torque to the inner wheel, the vehicle can then be pushed to straighten out – known as understeering.

To achieve torque vectoring effects in ICE vehicles, engineers have traditionally used advanced mechanisms like planetary gears or offset gears to superimpose and distribute torque from right to left across the differential. Automakers like Toyota, Mitsubishi, BMW and Audi have been using different types of sophisticated torque vectoring systems in performance cars for years.

UK-based GKN Driveline is one of the leading developers of mechanical torque vectoring systems, producing a few different products for various production vehicles. The company has a lot of experience developing complex clutch and gearing systems, including AWD couplings, disconnects, prop shafts, power transfer units and differentials. The company is the world’s largest producer of CV joints.

GKN’s latest torque vectoring technology, called Twinster, was introduced to the market as a system that is far less complex than other options. With no additional gearing or superimposed planetary gear sets to redistribute the torque, the system simply replaces the differential with two clutches that allow it to control the torque to each wheel individually. GKN says that Twinster’s simplified torque vectoring concept (found on the Ford Focus RS and Range Rover Evoque) provides almost identical performance to other, more complex systems.

In recent years, GKN has also been building up its electrification bona fides, producing electric drive transmissions and electric axle products that help automakers turn vehicles in many different segments into PHEVs. Versions of its eAxle can be found on production PHEVs from Volvo, Porsche, BMW and Peugeot Citroën.

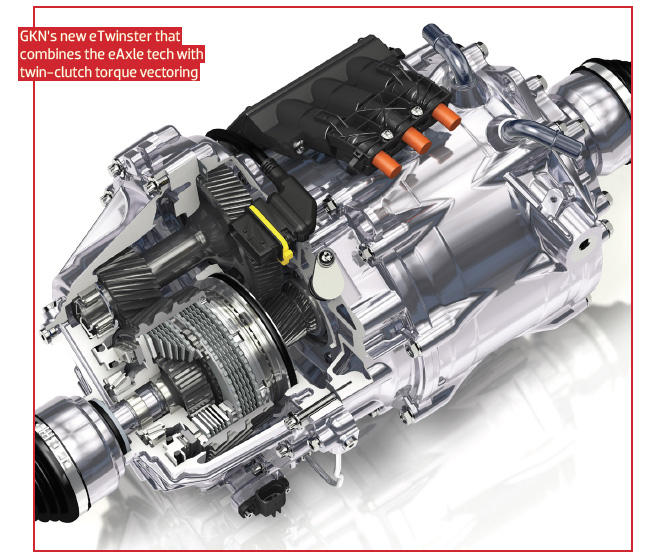

The company’s latest electric drive concept combines these two areas of expertise. The eTwinster system – designed to make it simpler for vehicle platforms to offer electric all-wheel drive and torque vectoring – is a combination of GKN’s eAxle and Twinster twin-clutch torque vectoring systems.

Charged recently talked to Theo Gassmann, GKN’s Advanced Engineering Director, to learn more about why the company decided to combine these two technologies into the eTwinster.

Charged: You developed the eTwinster with a focus on creating better PHEVs, is that correct?

Gassmann: Yes, we initially developed the eAxle as an electric-driven secondary axle for axle-split hybrid systems. Vehicles like the BMW i8, Porsche Spyder 918, PSA 3008 Hybrid, and Volvo XC90 T8 currently use the eAxle on either the front or rear axle. So, the concept of having a primary combustion drive and secondary electric drive axle has been on the market already in many different configurations.

Around the same time as the eAxle, we launched the Twinster coupling technology. So, now what we have done with the eTwinster is combined the torque vectoring technology with our electric drive hybrid technology. So it’s an electric-driven axle, and instead of having a differential to distribute the torque, we’ll use the Twinster’s two friction clutches, allowing individual torque control and management for each wheel. The combination offers degrees of freedom beyond all the mechanical and complex gearing torque vectoring systems.

We believe PHEVs are a great target for torque vectoring, because when you hybridize a vehicle, you add a lot of redistributed weight that changes the behavior of the base car. The weight naturally has a negative impact on responsiveness, so you can use torque vectoring technology to not only compensate for the weight, but actually add more customer-relevant features than the base model. The result is more agility and more safety. Torque vectoring adds a lot of degrees of freedom and intelligent responses to support what the driver wants. You actually feel like a better driver because of the way the car responds. It adds a lot of pleasure.

You could also have a pure battery electric vehicle with two eTwinsters and 4-wheel drive. Then you have one of the best performance machines you can think up, no question.

Charged: At first glance, many engineers in the EV industry might look at the description of eTwinster and ask, “Why not use two electric motors on the one axle? Wouldn’t that be simpler?” Can you describe how the eTwnister would compare to a dual-motor system?

Gassmann: There are some pros and cons to each system. One of the main benefits of using two motors would be that you could apply negative torque to one side and positive torque to the other side – while with one motor in the eTwinster you can either break or drive. So, two motors offer that option for more torque vectoring potential – an additional degree of freedom.

However, there are also many drawbacks to using two motors, including cost, complexity and even performance limitations.

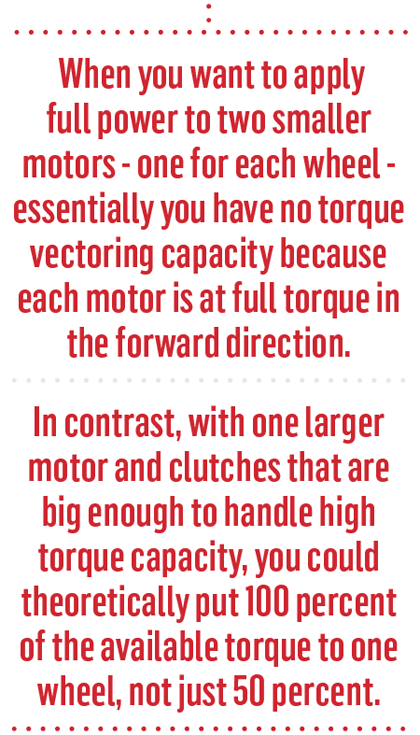

With dual motors there are some disadvantages in traction and torque vectoring functionality, particularly in full acceleration. When you want to apply full power to two smaller motors – one for each wheel – essentially you have no torque vectoring capacity because each motor is at full torque in the forward direction. It’s the same for both wheels.

In contrast, with one larger motor and clutches that are big enough to handle high torque capacity, you could theoretically put 100 percent of the available torque to one wheel, not just 50 percent. With the eTwinster, you have all of the torque available to redistribute it in a way that always keeps the maximum traction and driving performance. During full acceleration you have the ability to redistribute the torque and, for example, put 20 percent to one side and 80 to the other.

This is also important during critical traction situations, with one wheel on ice, for example. If you have two electric motors in this case, one motor is not providing any traction, because it’s just driving the slipping wheel. Again you have a lack of traction performance, because you’re splitting the power, more or less. Without an additional locking feature, you cannot put all the power to one wheel.

There are also cost and weight drawbacks to using two motors. Today, electric motors are still pretty expensive, and having two is significantly more expensive than having one bigger motor, even when you split the power 50/50. Most of the traction motors are high-speed lower-torque machines, so you still need a gear for each motor and in some cases even a disconnect, because the motors are not prepared to cover the entire vehicle speed. You end up with two complete electric drivelines for each wheel, and that adds a significant amount of weight and cost compared to a single-motor configuration.

So, given the technology available today and looking at weight and packaging cost, a single motor is still the preferred configuration, and the Twinster technology is a very reasonable and affordable way to provide additional traction and stability enhancement.

I think in the future, maybe 10 to 20 years from now, direct-drive wheel motors could become a reality. If the technology continues to improve, wheel motors could be a different story in terms of packaging and cost.

Charged: Are there drawbacks to using clutches in terms of response time, i.e. how many times you can adjust the torque distribution per second?

Gassmann: No. It is negligible, because the advanced clutch response time we achieve in today’s application is so close to that of an electric machine. And you typically have some other factors in the car which limit the response time – like the CAN bus refreshment rates or some delay in the data processing – and these are the same factors that limit an electric motor.

Also, it’s true that motors have an extremely fast response time, however in many automotive applications engineers actually have to slow them down to smooth out the responsiveness. If they react too quickly, it’s not a comfortable feeling for the passengers.

Charged: Do you think torque vectoring will be best suited for a particular segment of PHEVs – like SUVs, luxury or performance vehicles?

Gassmann: Quite the contrary. In fact, we think it will be really important when you start talking about having different vehicle segments on one platform.

Torque vectoring technology can help you give the vehicle any character you want, without actually changing the suspension or powertrain configuration in a major way. With the same hardware, you can provide a very different driving feeling, which means you can create a one-drivetrain-fits-all kind of approach. Then it comes down to the software, tuning and refinement for any specific segment you want to address.

The axle-split hybrid vehicles are actually not easy to tune. They can be run in front-wheel drive, rear-wheel drive, battery-only, or a blend. And drivers don’t want to be able to notice which mode the vehicle is in. They expect the car to behave repeatably and predictably. So eTwinster torque vectoring tech can actually help you maintain the character of the car in all modes. And any vehicle that has traction controls – ABS, etc – has the proper sensor technology and required information on the CAN bus to do very sophisticated torque-vector controls as well. Modern cars have all the acceleration and yaw data you need.

So that’s another great feature of torque vectoring. It offers an unparalleled amount of flexibility in terms of what the vehicle feels like while driving.

This article originally appeared in Charged Issue 24 – March/April 2016. Subscribe now.