Wide Bandgap (WBG) semiconductor technologies are attracting a lot of attention, and research funding. In January, the Obama administration selected a consortium of businesses and universities to lead an innovation institute focused on WBG materials. Japan and the UK are also funding R&D in the field.

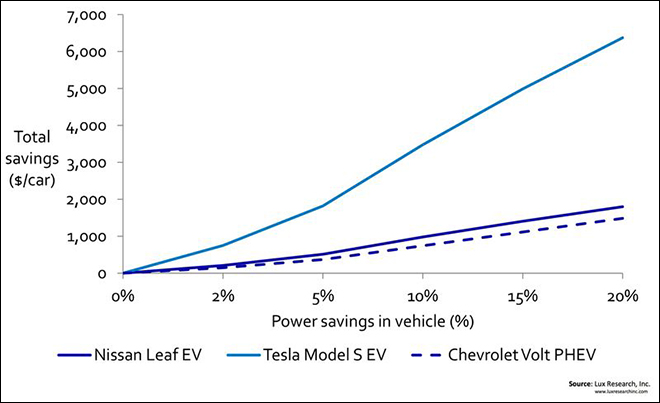

A new report from Lux Research, Silicon vs. WBG: Demystifying Prospects of GaN and SiC in the Electrified Vehicle Market, evaluates the benefits of WBG materials, and predicts a timeline for the commercial introduction of WBG-based power electronics.

So, what’s all the fuss about? According to the new report, WBG materials such as silicon carbide (SiC) and gallium nitride (GaN) can improve efficiency and reduce the high cost of battery packs – for example, Lux says a 20% power savings could lead to savings of $6,000 in the cost of a battery pack the size of that in the Model S.

A bandgap is the energy needed to excite electrons from a material’s valence band into the conduction band, and WBG materials have bandgaps significantly greater than that of silicon. Silicon (Si) has a bandgap of 1.1 eV (electronVolt); silicon carbide (SiC) has a bandgap of 3.3 eV, and gallium nitride (GaN) has a bandgap of 3.4 eV.

The wider bandgaps allow the WBG materials to withstand far higher voltages and temperatures than silicon. This means they can operate at higher temperatures, and have greater durability and reliability at higher voltages and frequencies, which in turn allows them to achieve higher performance while using less electricity.

SEE ALSO: A closer look at the semiconductor switch

WBG semiconductors can eliminate up to 90% of the power losses that currently occur during AC-to-DC and DC-to-AC conversion, and they can handle voltages more than 10 times higher than Si-based devices. Applied in an EV, WBG materials could cut electricity losses by 66% during vehicle battery recharging, according to the DOE.

“Efficient power electronics is key to a smaller battery size, which in turn has a positive cascading impact on wiring, thermal management, packaging, and weight of electric vehicles,” said Lux lead author Pallavi Madakasira. “In addition to power electronic modules, opportunities from a growing number of consumer applications – such as infotainment and screens – will double the number of power electronic components built into a vehicle.”

According to Lux, SiC diodes lead GaN in technology readiness, and will attain commercialization sooner – SiC diodes could be adopted in vehicles by 2020.

Source: Lux Research via Green Car Congress