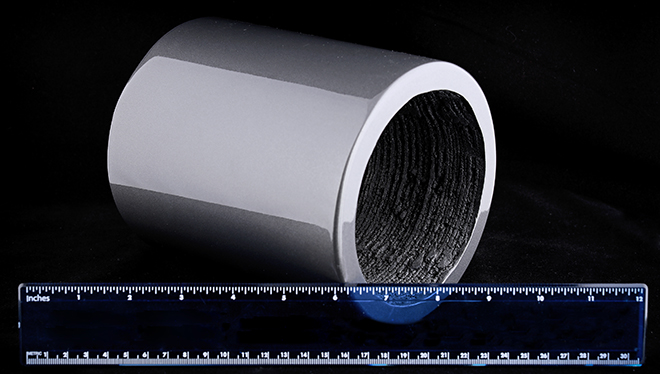

Magnet Applications, a manufacturer of specialty magnets, has announced a breakthrough in 3D-printed neodymium iron boron (NdFeB) magnets. NdFeB magnets are the most powerful known, and are used in applications from robotics to wind turbines to EVs.

Magnet Applications engineers, working with researchers at Oak Ridge National Laboratory, have shown that permanent magnets produced by additive manufacturing (3D printing) outperform traditional bonded magnets with less waste.

Magnet Applications manufactured the starting composite pellets with 65% isotropic NdFeB powder and 35% polyamide nylon-12 binder. The 3D printing was performed by ORNL’s Big Area Additive Manufacturing system.

“Additive manufacturing in magnets provides multiple benefits,” said Senior Technical Advisor Dr. John Ormerod. “They have more design flexibility, which is especially beneficial in sensor technology, and it creates less waste than the traditional sintering process.”

“With rapidly advancing technologies, the ability to manufacture the strongest magnet available in any shape without tooling, in any quantity, unleashes so many design opportunities. The work has demonstrated the potential of additive manufacturing to be applied to a wide range of magnetic materials and assemblies,” Ormerod continued.

Source: Nature