Editor’s note: After this article appeared in print, we received some feedback suggesting that the thesis is not clear enough. So, we’d like to point out a few things at the beginning.

- Today’s DC Fast Charging installations are very reliable. If you buy a production EV, such as a Nissan LEAF or BMW i3, it is unlikely that you will ever experience an interoperability problem with the charging hardware already installed around the world.

- This article is meant to highlight the fact that the process for testing the interoperability of new vehicles and charging hardware could be improved by third-party certification testing that is widely adopted. It is up to the industry to create a common certification test document for all types of DC Fast Charging and then pressure every stakeholder to adhere to it.

- There are a few organizations, not mentioned in this article, that have made significant strides towards eradicating interoperability issues – like IEC, SAE, Argonne National Labs and the CHAdeMO Association. However, the industry experts we interviewed all agreed that more needs to be done to push everyone towards a common certification process.

Here is the full article as it originally appeared in print.

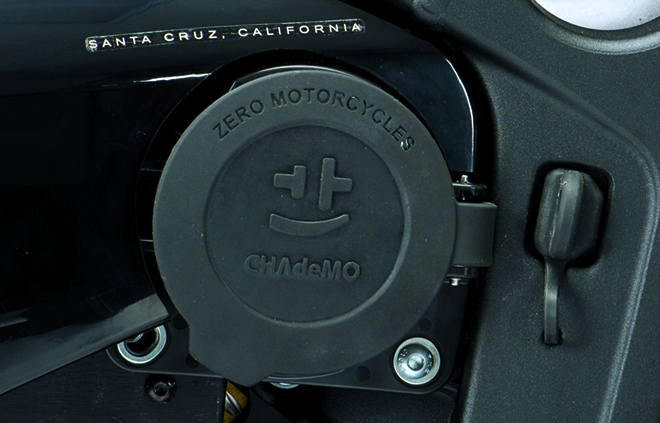

Here’s why interoperability testing is so important: Zero Motorcycles was forced to abandon plans to add a CHAdeMO fast charging option in 2013

Discussing standards and certifications in a compelling way is not always easy in an industry filled with sexy stuff to write about. There are the sleek fast cars, no shortage of controversy, and industry-wide distribution happening right before our eyes. Compared to these topics, the details of charging standards can seem like a real snoozer.

However, the story of Zero Motorcycles’ attempts to add a DC Fast Charging option offers a powerful illustration of why better standards and certifications are important.

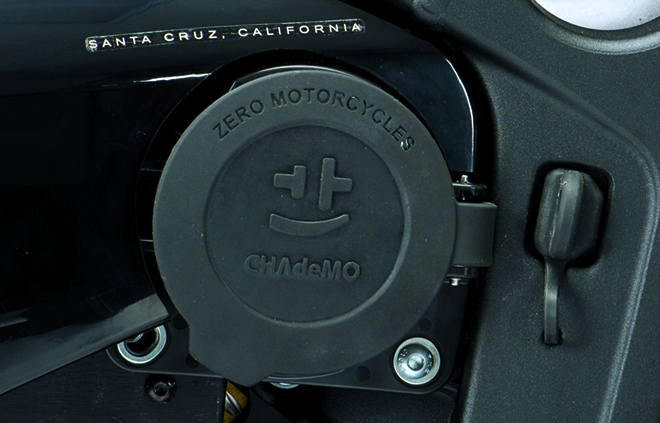

Back in 2013, Zero announced that it was adding a CHAdeMO accessory option to its bikes. At the time there were, essentially, no SAE Combined Charging Standard (CCS) chargers available for public use, and using that standard was never an option in any case, because of the relatively small size of a motorcycle’s battery pack.

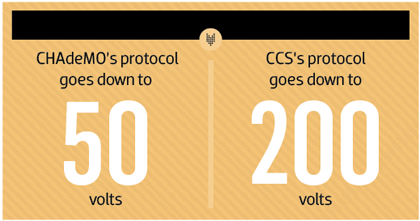

“The CHAdeMO protocol defines that the chargers must go all the way down to 50 V, whereas the CCS specification stops at 200 V,” Kenyon Kluge, Zero’s Director of Electrical Engineering, explained to Charged. “Our bikes had 100 V nominal packs, so we needed chargers to go down to about 90 V.”

The plan was to develop a CHAdeMO port attachment that only needed a few basic wiring connections and could be installed by Zero’s dealers when a customer requested it. The company bought a CHAdeMO charger made by ABB and used it to test the system in-house. It worked great, so they hit the road for some beta testing, and that’s when the problems arose. “We found out that many chargers were not adhering to the CHAdeMO spec,” said Kluge, “even though they were clearly marked as CHAdeMO chargers.”

Problems in the wild

Attempting to use chargers from many different manufacturers, Zero found a variety of issues.

In some cases, the chargers deviated from the CHAdeMO spec in ways that created problems specific to the motorcycle’s system. For instance, there were chargers that did not go down to 50 V, instead stopping at 200 V. This particular quirk is not something that would be easily illuminated by the other passenger EVs in production, as their battery packs have nominal voltages in the 300 V range.

There were also more general problems, like isolation check circuits that “were checking it to some insanely harsh value that was beyond what the spec dictated,” said Kluge. “It would come up with an isolation failure fault all the time, even though we met the CHAdeMO spec with megaohms of resistance.”

Other chargers had major communications problems, like noise issues that could get coupled to the CAN bus, or initial negotiation timing that was out of sync with the specification. “One charger had a noise issue that led to our bike-side CAN network going down,” said Kluge. “Not to mention the mouse pad on my laptop going wild. I had to disable it and use the keyboard only while charging.”

In the early days of EV rollout, from around 2010 to 2013, we heard similar reports of problems with Level 2 AC charging from many plug-in vehicle drivers. EVers took to the internet to share stories of chargers not working, working one day but not the next, and in some cases, not working when it was raining or humid outside.

It’s not uncommon to have bumps in the road in the early days of any new technology. And, to the credit of the big auto OEMs and charger manufacturers, we know that they worked tirelessly to increase the interoperability of the cars on the road and the installed base of chargers.

“It’s not a lack of desire,” said Kluge. In fact, Zero found some charging manufacturers to be very accommodating when it came to working through interoperability issues found in the field. “One company took one of our bikes to their test facility and worked for a few weeks to try and resolve all the issues, then pushed a firmware update out to their units.” Others, however, ranged from “mildly responsive” to “unresponsive.”

The biggest problem for Zero is that its customers don’t want to hear about the technical details of an interoperability problem, whose fault it is, or how the company is doing its best to fix it. From a driver’s perspective, they simply see an electric motorcycle with a CHAdeMO option that won’t work with every CHAdeMO charger.

That’s a bit of a nightmare from a public relations standpoint, when even rumors of reliability problems can do serious long-term damage to your brand. So, Zero decided to discontinue the CHAdeMO fast charging project.

Zero’s story is a cautionary one for other independent companies that are planning to build EVs enabled with DC Fast Charging options. Expect to spend considerable resources to ensure compatibility with chargers from dozens of different manufacturers. The big automakers have the manpower and deep pockets to make it happen, but for smaller companies it could be a daunting engineering effort.

The larger issue, however, is the lack of widely adopted certification processes that encourage everyone to meet the same clearly-defined specifications.

CHAdeMO 0.9 and 1.0

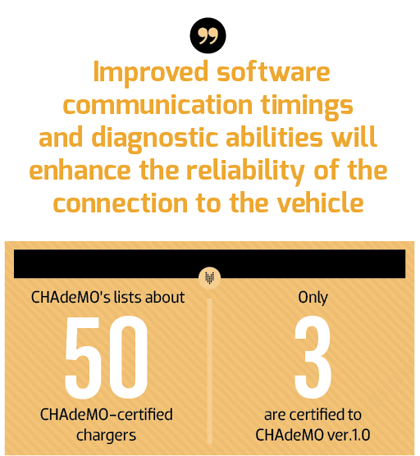

Beginning in 2012, the CHAdeMO Association started conducting certification tests to ensure interoperability between chargers and vehicles. Only certified chargers are allowed to display the smiley-face CHAdeMO logo.

The association’s website lists chargers from about 50 companies that have been certified. However, only three of those companies have designed their chargers to CHAdeMO’s latest and greatest specification, version 1.0. We asked ABB, the only global charger supplier on that short list, about the differences between CHAdeMO ver. 0.9 and ver. 1.0.

“CHAdeMO 1.0 enhances safety and protection of the vehicle,” explained Crijn Bouman, VP of ABB’s EVCI Product Line Management. “For example, better detection of equipment earthing [grounding] problems and better defined fusing protect the car in case of serious failures. Furthermore, improved software communication timings and diagnostic abilities will enhance the reliability of the connection to the vehicle.”

“ABB is a strong supporter of independent third-party testing and certification of both sides: the charger and the car interface,” said Bouman. “This will be a vital step to create true interoperability and a seamless charging experience in all cases. At the moment the industry is still in its infancy, with limited independent testing on SAE Combo, and some initiatives on CHAdeMO. We were the first global charger manufacturer to achieve CHAdeMO 1.0 certification by independent test house IDIADA. But more needs to be done.”

The fix

So what exactly needs to be done? In essence, there needs to be more industry pressure to push everyone towards a common DC Fast Charging certification process. It’s a critical step that has largely been ignored, in part because the big automakers have funded most of the fast charging infrastructure to date. That tight circle of OEMs has been able to work out all of the early interoperability issues with their cars, so there hasn’t been a strong push for certifications. The absence of third-party tests to tightly-defined standards has left others, like new EVSE manufacturers and vehicle builders serving niche markets, to figure it out on their own.

To be clear, there are worldwide validations and certifications specifically for safety. All charging products are tested for safe use to be sure they don’t present a shock hazard, for example. The interoperability problem is separate in that a charger can be safe to use but not function properly with all vehicles.

Recently, however, the industry took a big step towards a resolution by forming an Institute of Electrical and Electronics Engineers (IEEE) working committee to develop a draft standard. IEEE P2030.1.1 is a technical specification for DC Quick Charging, and it was approved on September 3rd.

IEEE is the world’s largest association of technical professionals, with more than 400,000 members. It’s not a body formally authorized by any government, but rather a community of engineers and stakeholders that develops global standards in a broad range of industries. There is a lot of respect for the thorough process it uses to develop and approve specifications, giving new momentum to the issue of DC charging certifications.

The chairman of the P2030 working committee is Nissan’s Joseph Thompson, an electronics engineer at the company’s North American Technical Center. “One of the main benefits of having an IEEE standard is to formally recognize a proven technology,” Thompson told Charged. “You can have a de facto standard simply by the quantities of a product in a marketplace, but an IEEE standard is about gaining international acceptance formally and allowing easier access to the technical details. IEEE members are international and across all industries, not just automotive. Members can log in to the IEEE site and get access to the spec – it’s a process they’re used to.”

A testable standard

IEEE P2030.1.1 includes technical specifications for both CHAdeMO and CCS charging systems.

Thompson believes that IEEE P2030.1.1 is detailed enough to be used as a basis for the certification process. He says the committee referenced the latest CHAdeMO and SAE CCS specs – with approval from the respective associations – and added a very comprehensive list of international standards that should be considered when developing a charger. They also added an annex about performance testing for the charging couplers with environmental screening. “Those plugs sit out in pretty tough environmental conditions, so we added a screening procedure for an equipment manufacturer to test their couplers’ reliability,” said Thompson. “That’s something new we’ve done that I haven’t seen in other standards.”

Some in the industry continue to express concern that SAE CCS technical definitions – which the IEEE standard points to – are still open to too much interpretation, and that it’s more of a guideline for design than a set of specifications. So, it’s likely that we’ll see more revisions to tighten things up as higher-volume EVs designed to use CCS hit the road in the next few years.

The next step towards eradicating future interoperability problems is working with product testing outfits like Intertek, TUV, and UL to offer a certification specifically for DC Fast Chargers using this common document. After that, it’s up to the marketplace to insist that chargers carry the certification.

The ideal is to have a single testable standard, so anyone can say, “As long as my vehicle design and your charger design can pass this standard certification test, they will work together.”

As Kenyon Kluge and Zero Motorcycles can attest, “that really wasn’t the state of the spec before.”

This article originally appeared in Charged Issue 21 – September/October 2015. Subscribe now.