In-wheel electric drive systems are a hot topic these days. Mounting the electric motor and power electronics within a wheel assembly can improve efficiency, save space and give automakers more flexibility in body design. This week, two leaders in the field introduced new in-wheel offerings.

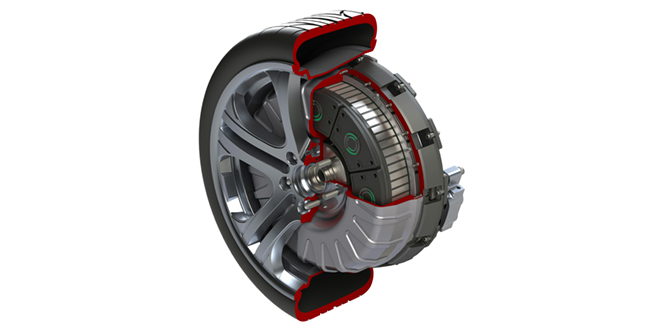

Protean Electric announced the debut of its production in-wheel motor at the 2013 SAE World Congress. The motors, which fit in the space behind the wheel, are designed to be “an integral part of a hybrid powertrain system when paired with a traditional internal combustion engine,” and are also “powerful enough to be the only source of traction drive in electric vehicles.”

Protean’s new motor can deliver 75 kW of power (100 hp) and 1,000 Nm (735 lb-ft) of torque, a 25% increase in peak torque over the previous generation’s design. Each motor weighs 31 kg (68 lbs). Regenerative braking capabilities allow up to 85 percent of available kinetic energy to be recovered.

“Protean Electric is ready to enable the global automobile industry as it moves to high volume, low cost hybrid and electric drive powertrains,” said CEO Bob Purcell. “Our system can be applied to current vehicle platforms, retrofit existing vehicles or create all new architectures for the future.”

Protean has developed several demo vehicles, including a Vauxhall Vivaro cargo van, a GAC Trumpchi sedan, a Ford F150 pick-up truck, and BRABUS electric and hybrid vehicles based on the Mercedes E-Class.

Meanwhile, at the auto motor und sport-Kongress 2013 in Stuttgart, Schaeffler presented its E-Wheel Drive. A development vehicle based on a Ford Fiesta features two units installed in the rear wheel arches. The electric motor, power electronics, controller, brake, and liquid cooling system are all installed inside the wheel rim.

Schaeffler’s E-Wheel Drive offers 40 kW of power per drive, continuous output of 2 x 33 kW (110 and 90 hp, respectively), and up to 700 Nm of torque. In comparison to Schaeffler’s first-generation wheel hub drive, which it exhibited in an Opel Corsa-based hybrid concept in 2010, the new drive features an output increase of one third, as well as 75% more torque. Each E-Wheel Drive weighs 53 kg.

Schaeffler CTO Professor Peter Gutzmer explained the advantages of in-wheel drive: “For electric vehicles used in urban environments, which may become obligatory in many densely populated areas, the wheel hub drive makes previously unheard-of space savings possible. In these new vehicle concepts, all components that are relevant for propulsion, braking, and driving safety are housed inside the wheel. The vehicle platform therefore provides maximum space for passengers, luggage, and for the battery, electronics, and communication systems. And vehicle manufacturers can use this as a basis for a range of different body designs.”

Using two wheel hub drives also allows torque vectoring – the selective distribution of torque to the wheels. “Wheel hub drives also provide significant advantages in terms of maneuverability, driving dynamics, and active safety,” said Professor Gutzmer.

Sources: Protean, Schaeffler