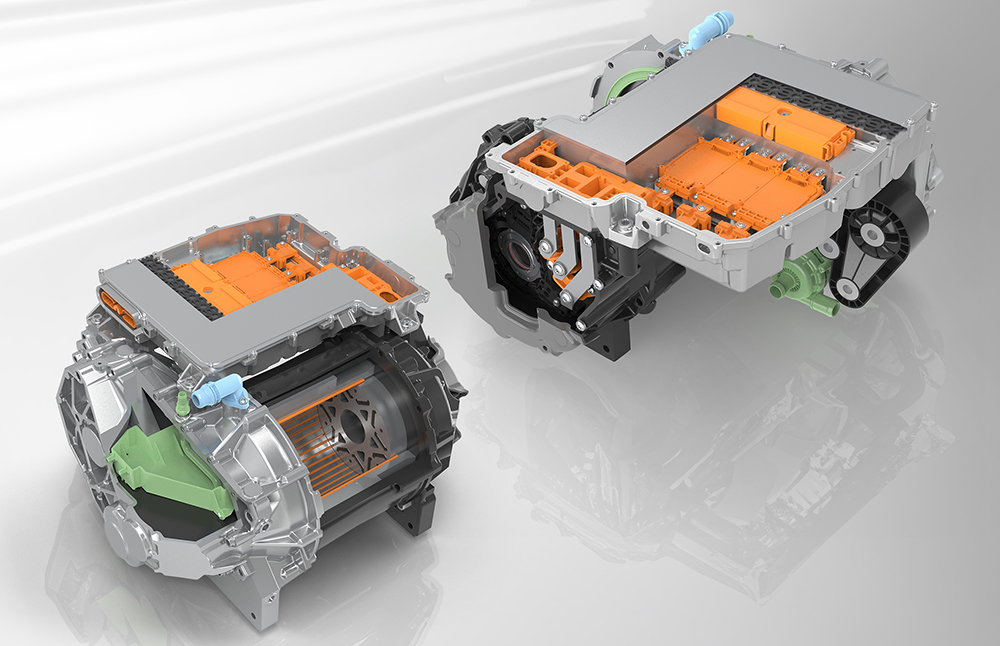

German chemical manufacturer BASF offers a portfolio of engineering plastics that can be used in co-creation partnerships with the automotive industry to develop next-generation EV motors.

- BASF’s portfolio of thermoplastics offers high temperature and media resistance, mechanical strength, exact electric compatibility, high purity and tailored flame retardance. The range includes:

- Ultramid (PA: polyamide)

- Ultradur (PBT: polybuthylene-terephthalate)

- Ultrason (PESU/PSU/PPSU: polyarylethersulfones

- Ultramid Advanced (PPA: polyphthalamide)

The compounds are available in different colors, from colorless to orange and laser-markable black, and feature short-glass, long-glass or mineral fiber reinforcement as well as various heat stabilizers.

The thermoplastics for EV motor parts can be easily processed in injection molding so that no post-processing is needed. They are weldable and offer flexible part design for different requirements, including high-voltage insulation, thermal management, hydrolysis and chemical resistance and high mechanical load. They can contribute to weight reduction as well as noise, vibration and harshness (NVH) reduction.

The plastics can be used in the motor and inverter housings, stator/rotor, busbars, IGBTs, high-voltage connectors, slot liners, bearing cages, magnetic encapsulation, engine mounts and other components.

Source: BASF