A battery management system requires precise current measurements in order to derive State of Charge (SOC) and other important battery state information. To date, commercial shunt measurement systems are limited in their accuracy by two main factors. First, accuracy is affected by changes in temperature caused either by the environment or by the self-heating of the shunt when high currents are flowing. Second, historically, due to limitations imposed by offset error and noise, lower-resistance shunts could not be used to meter small currents. Instead, a high-resistance shunt must be used. Such shunts dissipate considerable heat and must be physically large.

Sendyne’s new SFP101 current, voltage and temperature measurement IC and board addresses these issues. The SPF101 is designed to achieve a maximum voltage offset error of less than ±150 nanovolts. It also provides user-definable automatic compensation for resistance dependence of the shunt on temperature from -40° C to +125° C, and is programmable to accommodate shunts with an output voltage from ±10 mV to ±300 mV.

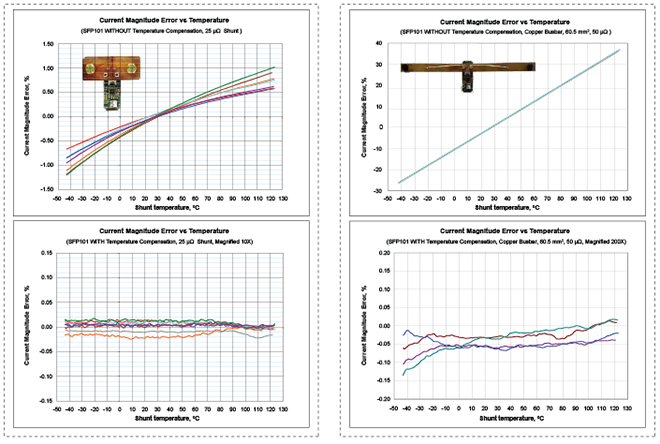

According to Sendyne, this means that the SFP101 can work with a shunt of essentially any resistance made from any material. For example, a copper busbar can have as large as a 35% error over temperature, making it unsuitable for use in exact current measurement. Due to the proprietary temperature compensation feature of the SFP101, that error is typically reduced to ±0.1%.

Using a 25 micro-Ohm or 100 micro-Ohm shunt, the SFP101 typically achieves ±0.05% accuracy of current measurements. A 25 micro-Ohm shunt, such as those produced by Vishay, can now be used for high-power applications, handling continuous currents of 300 A and peak currents of 2000 A while resolving currents as small as 250 μA.

The SFP101 also provides on-board calibration for both current and voltage, storing calibration values and applying them internally, and offers separate charge, discharge, and total Coulomb counters and measures multiple temperature points to ±1° C.

Correction: A previous version of this post contained an image of a battery-pack system display made by Saint-Gobain Performance Plastics. The image is not directly related to this news of Sendyne’s products and it has been removed to avoid further confusion.

Source: Sendyne