Lithium-metal anodes are the favored solution for next-generation Li-air or Li-sulfur batteries for various reasons, including their high specific capacity (theoretically tenfold higher than graphite). However, safety issues resulting from dendrite formation and instability caused by volume expansion have slowed the development of commercially viable solutions.

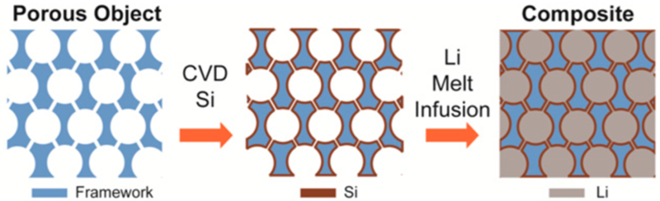

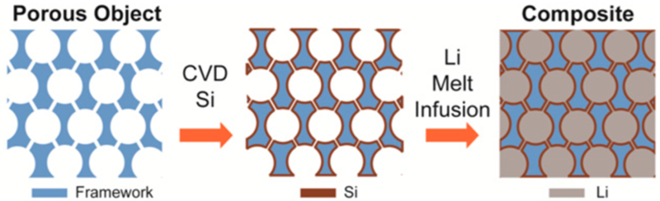

In “Composite lithium metal anode by melt infusion of lithium into a 3D conducting scaffold with lithiophilic coating,” published in Proceedings of the National Academy of Sciences (PNAS), a team at Stanford led by Professor Yi Cui has introduced a new approach to address both of these issues by encapsulating lithium inside a porous host scaffold using a facile melt-infusion approach.

Uniformly confined within the matrix, the lithium creates a material that can deliver a high capacity of around 2,000 mAh/g (gravimetric) or 1,900 mAh/cm3 (volumetric) as a stable anode for Li-metal batteries.

For a scaffold to serve as the Li host, the researchers used an electrospun carbon fiber network. They coated the carbon fiber network with a lithiophilic coating, then infused the molten lithium, which flowed easily into the scaffold and occupied the empty spaces between each single fiber.

“This novel design affords remarkable battery performance with a low interfacial impedance, stable voltage profile and long cycle life, due to its high conductive surface area, stable electrolyte/electrode interface, and negligible volume fluctuation,” writes the Stanford team. “Compared with a hostless Li metal electrode, this Li/C composite electrode has multiple advantages and can open a new avenue for solving the intrinsic problems of Li metal-based batteries.”

Source: PNAS via Green Car Congress

Image: Liang et al