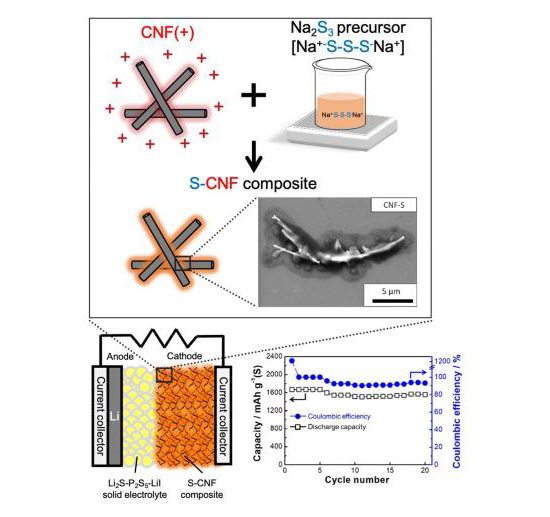

Scientists at the Toyohashi University of Technology have made an active sulfur material and carbon nanofiber (CNF) composite using a low-cost liquid phase process. Their paper, published in the American Chemical Society’s ACS Applied Energy Materials, claims that all-solid-state lithium-sulfur batteries using a sulfur-CNF composite material show higher discharge capacity and better cycle stability than lithium-ion batteries.

All-solid-state batteries have attracted attention as next-generation batteries because they have five times the potential energy density of conventional lithium-ion batteries. But because sulfur is an insulator, it must be provided with an ionic and electron-conductive path. To address this, the researchers synthesized cathode composites by combining a sulfur active material and carbon nanofiber (CNF) using an electrostatic assembly method, which can uniformly combine materials in a solution. The batteries showed high discharge capacity, even after repeated charge-discharge cycles.

(C) TOYOHASHI UNIVERSITY OF TECHNOLOGY. ALL RIGHTS RESERVED.

One of the paper’s co-authors, Professor Nguyen Huu Huy Phuc, explains: “Conventionally, sulfur-carbon composites were synthesized by mechanical mixing—liquid mixing using a special organic solvent and complicated methods—in which sulfur is combined with a porous carbon material with a high specific surface area. We focused on making a sulfur-carbon composite using a low-cost and simple electrostatic adsorption method which can uniformly combine nanomaterials.”