GKN Driveline has announced a major expansion of its European eDrive production facility in Bruneck, Italy, as the company moves to serve increasing demand for electric and hybrid vehicle programs from OEM clients.

The company will increase its current 11,000-square-meter floor space by more than 60%, to create an 18,000 sq m facility dedicated predominantly to eDrive production. The site now employs approximately 800 people. Between 70 and 80 employees will move into eDrive manufacturing, and other driveline production will be relocated to the company’s other sites in Europe. The expansion will also help facilitate increased production of AWD technologies, such as electronic torque management units.

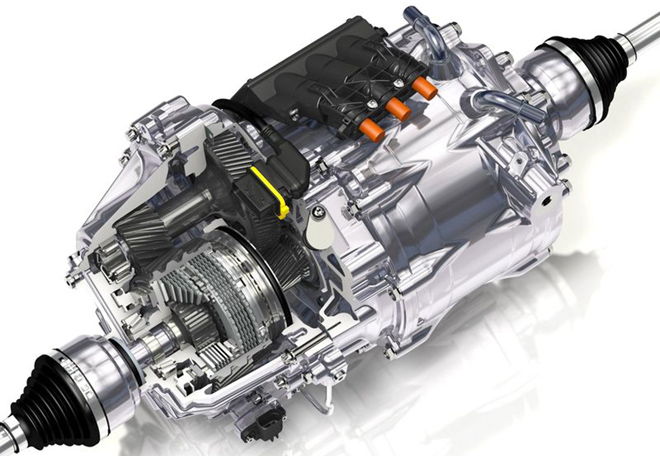

By the time the project is completed in 2019, the Bruneck facility will be predominantly focused on eDrive production. The site’s manufacturing portfolio includes the PACE coaxial eAxle, featured on Volvo plug-in hybrids, the two-speed eAxle used on the BMW, and AWD products such as GKN’s Electronic Torque Management systems.

GKN also manufactures eDrive systems in Japan, and it will begin production in China next year with its joint venture partner, SDS.

“Bruneck has already established itself as a center of excellence for the production of leading electric driveline systems,” said Peter Moelgg, GKN Driveline All-wheel and eDrive CEO. “This major expansion will enable eDrive production to move up a gear, to deliver the growing number of programs won by GKN for next-generation hybrid and electric vehicles.”

Source: GKN Driveline