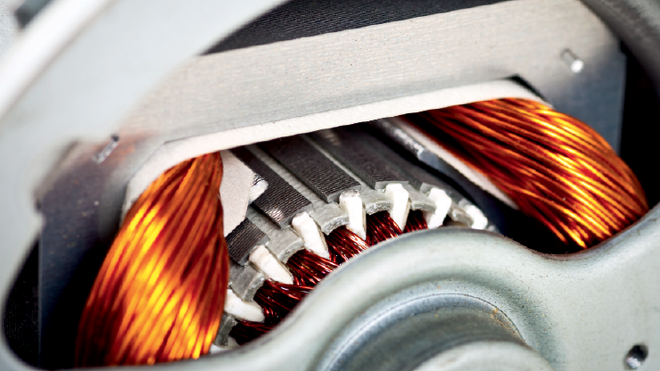

Innovate UK is sponsoring a number of competitions to spur companies to develop emissions-reducing vehicle technologies, with millions of pound in grant money for the winners. One of these is Make it Lighter with Less, which aims to improve the efficiency and performance of electric motors.

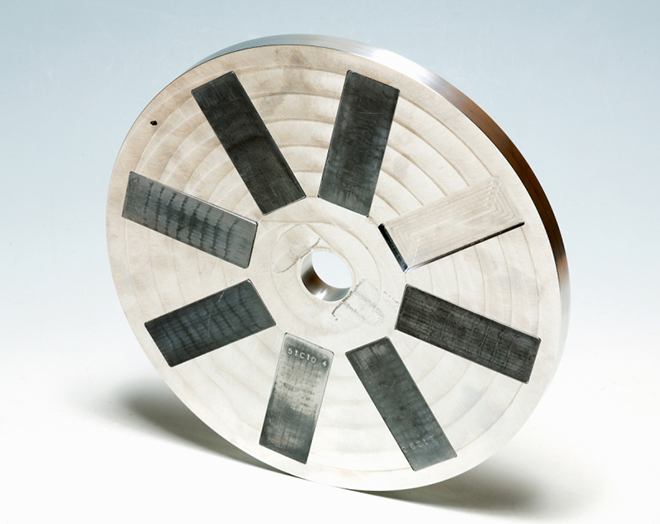

This project is led by Alvant, a specialist in aluminum matrix composites (AMCs), in collaboration with GE Aviation, YASA Motors and the National Composites Centre. Alvant’s researchers have achieved a 40-percent rotor weight saving on an axial flux electric motor while increasing the rotor’s potential power-to-inertia ratio.

Alvant’s proprietary AMCs enable components to be optimized for strength-to-weight and stiffness-to-weight ratios. The company’s Advanced Liquid Pressure Forming method can selectively reinforce areas of a component with one of its performance materials in a near net shape manufacturing approach. Alternatively, Alvant’s materials can be applied as discrete inserts into a component.

According to Alvant, in an axial flux motor application, its technology can not only save weight – the component’s lower mass and reduction in force means engineers may be able to eliminate the number of fixing bolts required, reducing the bill of materials and assembly time.

“Using AMCs, we have been able to attack the weight yet retain the stiffness of the electric rotor, to minimize parasitic mass, improving the power-to-inertia ratio and therefore efficiency and responsiveness,” says Alvant Commercial Director Richard Thompson. “We can also offer better thermal resistance, up to 300° C, making AMCs a more suitable material than polymer composites for applications such as motors, batteries, energy recovery systems, fans and flywheels.”

Source: Alvant via Green Car Congress