DC fast charging isn’t just a godsend for EV drivers looking for a quick charge. It’s also an entirely new level of consumer electronics.

“You and I, as members of the general public, have previously never had access to anything higher in voltage than what we see at home in our wall socket,” Tim Patel, Global EV Charging Business Development Manager at Littelfuse, told Charged. “Some of these newer chargers are pushing 400 V DC, all the way up to 1,000 V DC, of electrical energy.”

To put that in perspective, wall sockets in North America provide 120 V AC. DC fast chargers are on their way to becoming the highest-power devices people will interact with outside of industrial settings. But what does that entail in terms of design?

“There’s clearly a different set of rules to abide by to make sure that you and I remain safe when we use these pieces of equipment,” Patel continued.

DC fast chargers are on their way to becoming the highest-power devices people will interact with outside of industrial settings.

Littelfuse is a circuit protection company that was founded almost a century ago to manufacture fuses. Today, the company has diversified its portfolio to include power semiconductors for DC fast chargers. Considering its years of circuit protection experience, Littelfuse is uniquely positioned to address the new set of rules that apply to high-power DC fast chargers.

“When it comes to EV chargers, we really have three pillars that we stand on, and those are safety, efficiency and reliability,” Patel said.

Personnel protection

One clear concern when it comes to high-voltage DC fast chargers is the risk of electric shock. Will EV drivers have to wear insulated safety gloves whenever they want to charge their batteries? Clearly not – but ensuring user safety is of the utmost importance.

“The voltage is higher, and when it comes to a person being able to touch a panel or enclosure that’s sitting outdoors, there needs to be a mechanism to ensure that the supply can be shut off if there’s any kind of fault between the internal electrical parts and the external housing,” Patel said.

Such a mechanism is called a ground fault circuit interrupter (GFCI). A GFCI is a device that monitors electrical current to ensure it takes the correct path. If the current takes an unexpected path – for example, through a human body – the GFCI will immediately break the circuit.

“You and I as normal people have never had access to this level of DC voltage before,” Patel reiterated. “So there’s very specialized ground-fault protection. It’s actually DC ground fault protection that’s built in at the output side to make sure that when we pick up the nozzle, the circuit’s not energized. And if it ever were to be accidentally energized, the GFCI would monitor it to such a degree that we’d never be under the threat of getting an electrical shock.”

Patel refers to this type of safeguard as ‘personnel protection,’ but it’s not just us fleshy humans at risk of electric shock. Many circuit components, such as the semiconductors used in EV chargers, are also sensitive to high voltage. It’s important to ensure that these components are not exposed to more voltage or current than they can handle.

There’s very specialized ground-fault protection. It’s actually DC ground fault protection that’s built in at the output side to make sure that when we pick up the nozzle, the circuit’s not energized.

Semiconductor protection

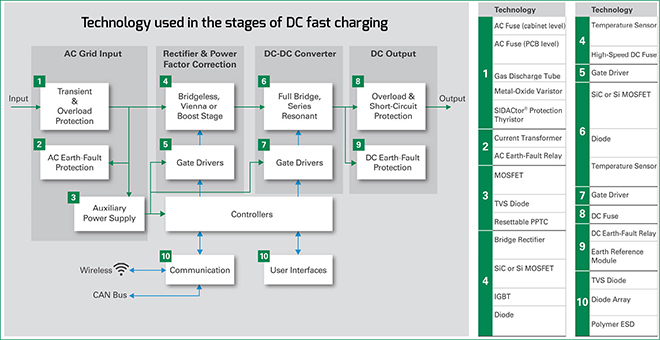

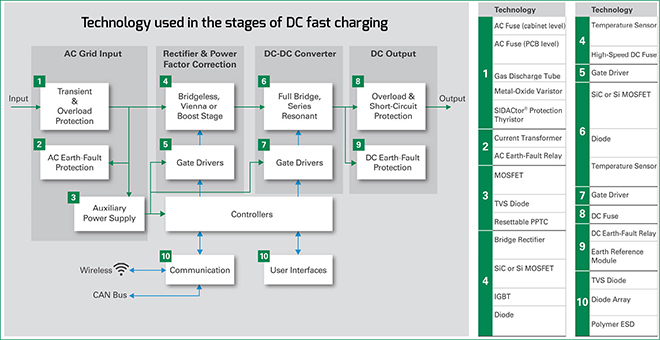

There’s a lot of electrical engineering that goes into making a DC fast charger, and a lot of (metaphorically) moving parts. To convert the grid’s AC electricity into the high-voltage DC used to charge an EV battery, you need semiconductor technology such as diodes, rectifiers, MOSFETs, and IGBTs. Each of these components requires protection against an unexpected swell of current. Fortunately, this protection can be provided by Littelfuse’s bread and butter: the humble fuse.

“They could be traditional fuses, which is more for regular AC inputs to power supplies for overcurrent protection,” Patel said. “Or they can be a little more specialized, like some of our newer products, called high-speed fuses, which are directly intended to protect semiconductors. They actually have a very specific time-current characteristic that’s engineered into them, so that they operate very quickly compared to traditional AC input fuses.”

In addition to providing overcurrent protection, fuses can mitigate risk to personnel. For example, a short circuit within a semiconductor module is bad for the module, but it could be even worse for people nearby.

“Those kind of events could actually cause the case of the [semiconductor] device to rupture,” said Patel. “And when that happens, given the voltage and current that’s being used here, there’s really no telling how drastic that case rupture could be. In some cases, it could actually be explosive enough to cause metal pieces to shoot out of the enclosure and possibly get access to the outside world. If someone’s standing nearby, it would be a bad thing. So these high-speed fuses are designed to make sure that they cut off supply to those semiconductors before that level of drastic fault ever has a possibility of occurring.”

Another concern for sensitive semiconductors is an unstable power supply. The power grid can be made unstable, or noisy, by nearby electrical loads. For example, if your EV charger is located near an industrial facility with large motors, the switching on and off of those motors can produce spikes in the power supply. These spikes can wreak havoc on power semiconductors, Patel points out.

“We have some technologies in the form of metal-oxide varistors, which are ceramic devices that absorb a lot of transient voltage energy,” he said. “And another technology called gas discharge tubes, also known as spark gaps, can absorb levels of transient energy. They see the most use in lightning surge protection. If there’s a nearby lightning strike and there’s some transient voltages that get electromagnetically induced into the power lines, those could propagate into a power supply in a fast charger. These over-voltage protection devices will absorb that energy, preventing it from going into the sensitive electronics that actually make the charger work.”

High-power chargers

Though there aren’t many high-power chargers (defined as those operating above 50 kW) currently on the market, that may soon change. “I believe the highest [charger being tested] out in the marketplace now is at 475 kW of power,” Patel said. He points out that the ability to charge an EV at roughly the same rate as refueling an ICE vehicle is critical to increasing EV adoption – and the more power a charger can deliver, the faster an EV can be charged.

There are two parameters that affect the power of an electrical circuit: voltage and current. Increase one or the other, or both, and you increase the power. However, increasing the current of EV chargers has drawbacks. For one thing, higher currents produce more heat. This can be mitigated by increasing the size of the charger cable, but this creates other problems. After all, a cable can only get so big before consumers simply can’t wield it. Increasing the voltage, on the other hand, does not cause these problems. Thus, the EV industry has settled on voltage as the key to increasing charging power.

“The only really practical way to push power is to increase the voltage and keep the current at the same levels,” Patel said. “That allows you to have the most reasonable cable size, minimize the amount of copper that you need, and make it still usable, not too heavy for the user to actually pick up and plug into the car.”

Although the next-generation DC fast chargers that are being tested today max out at roughly 1,000 V, Patel expects the EV industry to eventually standardize at 1,500 V. This would allow EV chargers to match power sources such as solar panels, allowing for better integration in the future.

The end goal is to harmonize on a voltage that can also be integrated with other sources of energy – not just the grid, but things like solar panels, which have already standardized at 1,500 V for solar farms.

“We really see the industry topping off at 1,500 V DC, and that could be several years down the road,” said Patel. “But the end goal is to harmonize on a voltage that can also be integrated with other sources of energy – not just the grid, but things like solar panels, which have already standardized at 1,500 V for solar farms, as well as wind energy and local energy storage systems.”

Fast charging standards

In addition to these design considerations, there are several regulatory standards that must be incorporated into EV chargers. EV charging standards depend on location. In North America, the UL 2202 standard for EV Charging System Equipment pertains to DC charging systems up to 600 V. UL 2202 includes several requirements for both personnel and circuit protection. In addition to UL 2202, the SAE J1772 standard constrains the power levels and architecture of charging systems by defining electrical connectors – that is, the plug that goes into your EV.

Outside North America, the most important global standard for DC fast charging comes from the International Electrotechnical Commission (IEC) in the form of IEC 61851 Electric Vehicle Conductive Charging System. IEC 61851-23 defines requirements for DC charging stations with an input up to 1,000 V AC and 1,500 V DC.

“IEC 61851 is the most international standard in terms of scope, so the Europeans adopted that and added some national deviations to comply with local electrical codes,” Patel said. “And some parts of Asia like China also adopted versions of that IEC standard, but also added their own specific requirements where they need it for their own electrical grid codes and standards.”

Front and center of EV charging challenges

Littelfuse isn’t stepping on the brakes when it comes to power semiconductor safety and efficiency. Earlier this year, the company acquired IXYS, a prominent semiconductor company. Littelfuse is also continuing to push the envelope on advancing semiconductor technology.

“We are looking at newer generations of technologies,” Patel said. “We are all-in in terms of development of our own silicon carbide technology, and the whole purpose of the newer semiconductor technologies is to really get the best levels of efficiency in a power converter design.”

Between the acquisition of IXYS and Littelfuse’s own research and development, the company is excited about its position in the EV charging industry.

“It puts Littelfuse really front and center when it comes to the main design challenges that a charging engineer would have,” Patel said.

This article appeared in Charged Issue 40 – November/December 2018 – Subscribe now.