After months of encouraging test findings, Oak Ridge National Laboratory (ORNL) battery researchers are suggesting that the solid-state battery industry focuses on isostatic pressing to commercialize next-generation batteries.

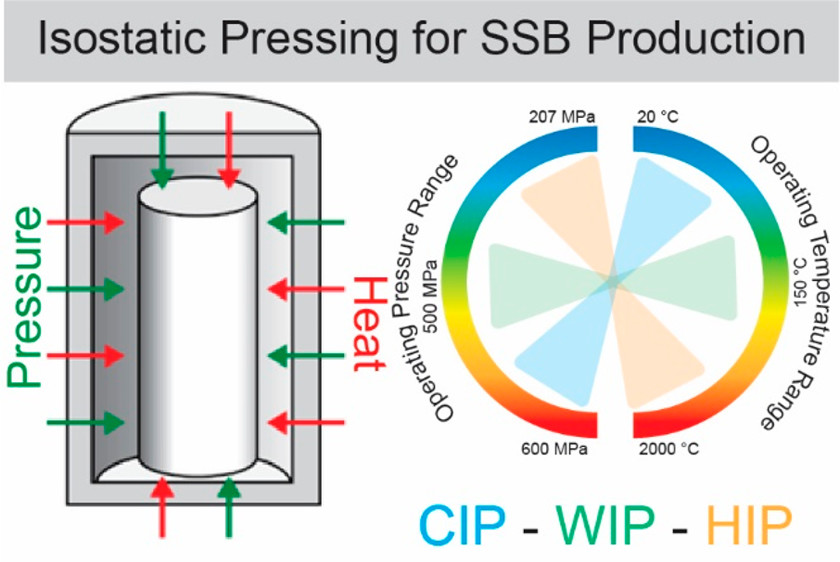

Isostatic pressing employs fluids and gasses like water, oil, or argon within a machine to exert consistent pressure throughout a battery component, generating a homogeneous material. This approach could speed up battery production and improve energy flow with the support of a pressing equipment manufacturer, ORNL researchers said in an ACS Energy Letters review paper.

Isostatic pressing creates thin layers of solid, homogenous electrolyte with strong contact for smooth ion transport. The approach works with different battery compositions, temperatures and pressures. Isostatic pressing of batteries was formerly done only at high or room temperature, but now low temperatures also give successful results. Isostatic pressing may also allow manufacturers to produce the three battery layers as a thick system rather than separately.

“Effectively addressing this challenge would leapfrog present-day battery technology into the next decades by enabling energy-dense solid-state batteries to meet the burgeoning demands of portable electronics, grid storage, electric vehicles and even [aviation] applications,” the research team stated.

Source: ACS Energy Letters