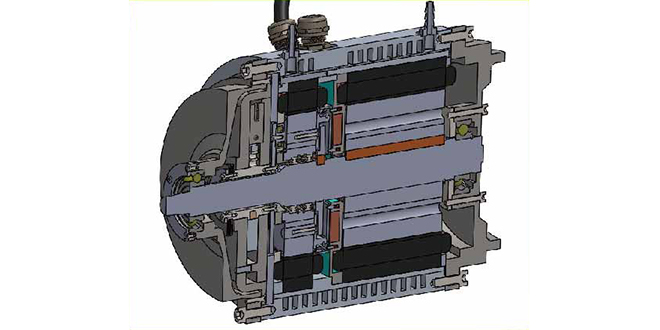

Scientists from Nanyang Technological University (NTU) and the German Aerospace Centre (DLR) have invented a 2-in-1 electric motor that integrates the vehicle’s traction motor with the air conditioning compressor, saving both space and energy.

“The biggest challenge with electric cars in tropical megacities is the range that they can travel on a charge, because their batteries are needed to power both the engine and the air conditioning,” said Professor Subodh Mhaisalkar, Executive Director of NTU’s Energy Research Institute. “In tropical countries like Singapore, up to half the battery’s capacity is used to power the air conditioning system.”

The team plans to develop a prototype, after which DLR will conduct further tests and improvements at its facilities in Germany, with the aim of eventual commercialization.

Prof Mhaisalkar said the new electric motor will not only help extend range, but will also cost less to produce, as it requires less material than its counterparts. Both the weight and size of the motor have been reduced.

“To increase the energy efficiency and therefore the range of electric cars, the thermal management and the integration of additional functions into existing powertrain components play a major role,” said Dr Michael Schier of DLR’s Institute of Vehicle Concepts. “By integrating the refrigerant compressor directly into the electric motor, we save components, weight and cost. Simultaneously, the more regenerative braking part of the kinetic energy is passed directly to the refrigerant compressor and thus the efficiency is further increased.”

SEE ALSO: Wide bandgap technology can make power conversion 90% more efficient

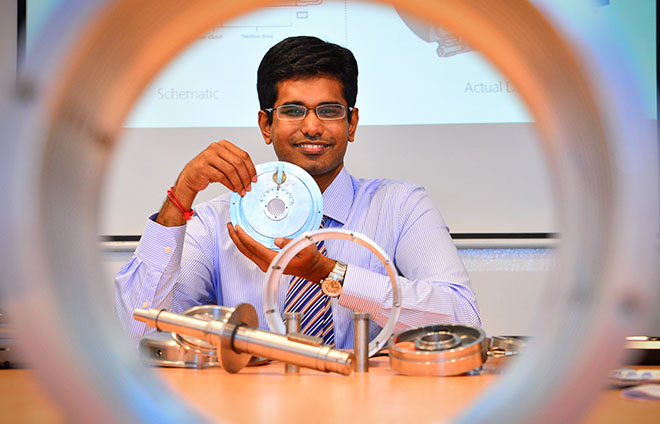

“Since we are now designing electric vehicles from scratch, I see no reason why we should keep both units separate,” said research scholar Satheesh Kumar. “As we have proven, combining the two gives us synergy – a more efficient use of electricity – and it also improves engine braking, which stops the car faster with lesser wear on the brake pads.”

Source: Nanyang Technological University via Green Car Congress