Sponsored by Nordson Sealant Equipment

Customers rely on Nordson to deliver improvements, efficiencies and solutions for a wide range of dispensing applications in their battery manufacturing processes. Nordson Sealant Equipment provides an industry-leading, field-proven range of automated dispensing solutions for one- and two-part materials used in battery cell bonding, battery cell power distribution and battery pack assembly.

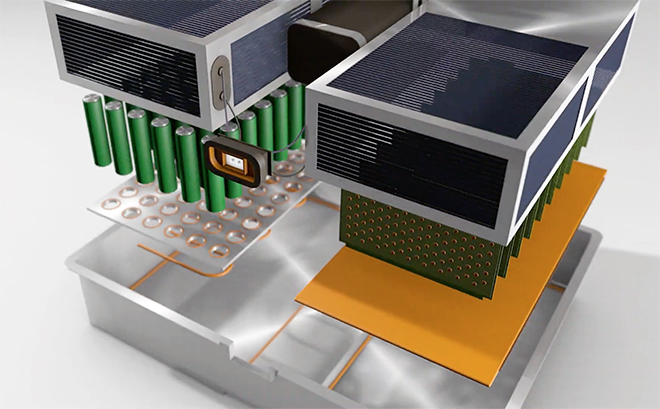

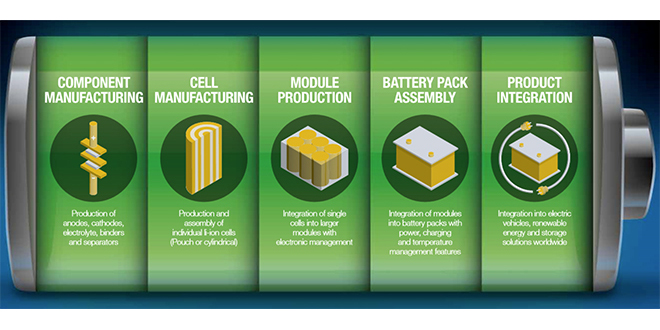

Overview: Battery cells are manufactured in many sizes to fit the end product, the most being cylindrical, prismatic and pouch styles. While the use of a specific cell shape is dependent on the battery pack design, dispensing methods for securing the cells into larger battery modules share common challenges.

The Nordson Solution: Module integration of cylindrical battery cells are often challenged by production speed and location accuracy; with the application and material knowledge, coupled with extensive robotic automation experience, Nordson designs engineered solutions that provide the correct number of dispense heads at the flow rate and robotic speed necessary for the application needs.

Square battery cells often experience air becoming wrapped around, or caught under, battery cells during a fill or pour. Nordson’s programmable dispense speeds allow for mid-shot adjustments in material flow rate, which allow air to escape from the fill. Speed can be adjusted back to full speed once the material is past the point of concern, allowing necessary production speeds to be achieved.

Battery Cell Power Distribution

Overview: Applying the exact bead size can be challenging; for long bead requirements of various patterns, the length may exceed the volume of the meter and require reload, resulting in a gap or overlap in the bead.

The Nordson Solution: Nordson specializes in bonding thermal interface materials between the current circuit and the battery cell module. Nordson uses continuous flow meters and can optimally size the meter to ensure reloads are not necessary before the end of the bead. Intricate bead paths can result in sharp turns where the robot slows down, causing the meter to deposit too much material. Nordson’s servo-driven meters have an auto-flow mode where the flow rate can be adjusted at the same time as the robot, allowing for even material placement along the battery cell or module.

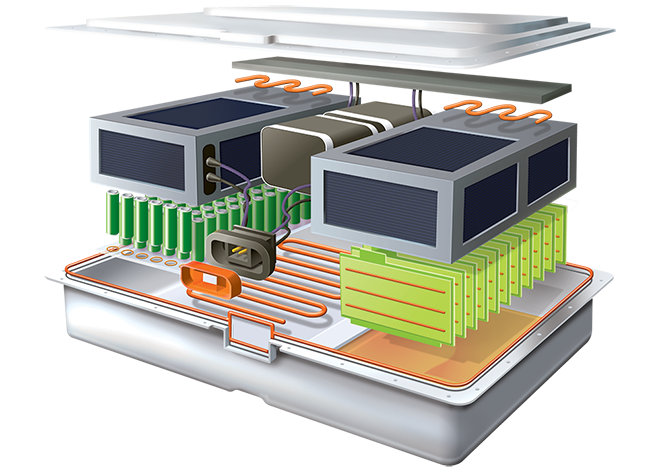

Overview: Ensuring a battery cell module provides enough power with the correct form and fit for the end product is no simple task. Typically, numerous modules are placed together to create a larger assembly of modules, also known as a pack. The shape of these packs varies greatly depending on the vehicle or the storage battery’s overall shape and are usually bonded together to reduce vibration problems or sealed to prevent corrosion issues due to moisture.

The Nordson Solution: Battery packs are bonded in one of two ways: bead bonding utilizes robotics to apply a precise amount of material to the face of each module; flood methodology simplifies robotic needs by applying material to the base of the entire battery pack to bond each module in place. A large meter needs to be mounted near or directly to the robot for both methods. Nordson’s continuous flow meters can be used for dispensing one- or two-component epoxies.

Battery modules are sealed with a bead that encapsulates the battery pack module or by a bead placed between a top and bottom cell module. Both sealing methods require accurate bead placement to ensure assembly compression does not overflow into battery cells or outside of the pack. Nordson’s variety of nozzles are specifically designed for precise application in difficult-to-access channels or locations.

Industry partnerships

Nordson Sealant Equipment works alongside adhesive manufacturers and automation/robot suppliers to ensure their solution is uniquely engineered to the customer’s application. Nordson’s volume displacement rod metering technology permits dispensing thermal gels or other heavily filled materials without packing out or wearing the equipment over time. Additionally, a wide range of wetted components and seal offerings allows Nordson’s dispensing equipment to be compatible with battery assembly materials across the globe, with many material suppliers incorporating the Nordson technology in their own test laboratories.

As global leaders in metering, mixing, and dispensing solutions for Battery Cell manufacturing applications, Nordson encourages early involvement in projects. Please reach out to Nordson Sealant Equipment’s team of experts to improve your production capabilities and performance.