CD-adapco has developed a set of Li-ion battery simulation tools designed to enable faster design and development of EV power systems. The new technology is available within CD-adapco’s flagship software package STAR-CCM+ and the application-specific Battery Design Studio.

The new software tools were developed as part of the DOE’s Computer Aided Engineering of Electric Drive Batteries (CAEBAT) project. CAEBAT’s objective is to incorporate existing and new models into design suites/tools with the goal of shortening design cycles and optimizing batteries.

“CAEBAT has provided us with world-class capabilities to model the performance and safety of Lithium-ion batteries,” said Johnson Control’s Director of Controls & Modelling Brian Sisk. “These technologies have helped us design innovative battery systems and enable new fuel-saving technologies for vehicles.”

“Continued progress developing and linking physics-based models of batteries allows developers to better understand the internal behavior of batteries and explore new designs in a virtual environment, reducing the number of prototypes and tests required by a traditional build-break design cycle,” said Ahmad Pesaran of the National Renewable Energy Laboratory. “This project is expected to enable scientists and engineers to further improve the performance, cost, and lifetime of advanced lithium-ion batteries in support of the DOE’s EV Everywhere Grand Challenge.”

CD-adapco’s solution combines flow, thermal and electrochemical simulation. The models span multiple computational domains, from systems models to complex 3D models.

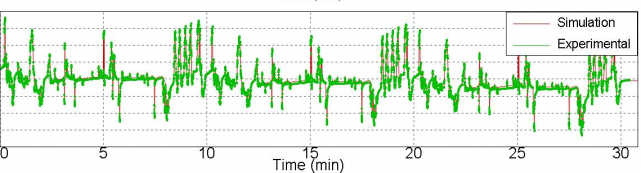

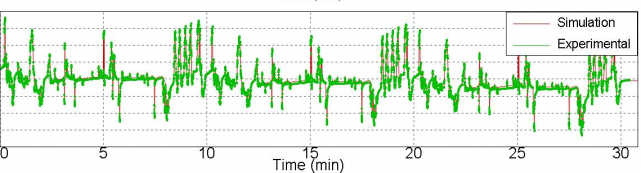

Predicted cell temperature during an automotive drive cycle.

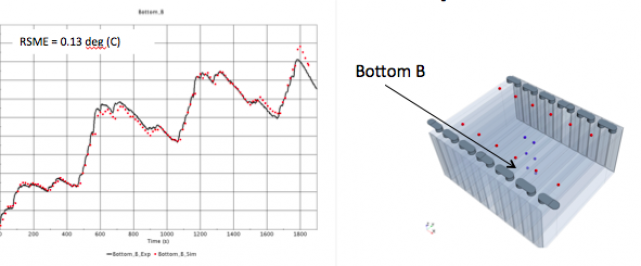

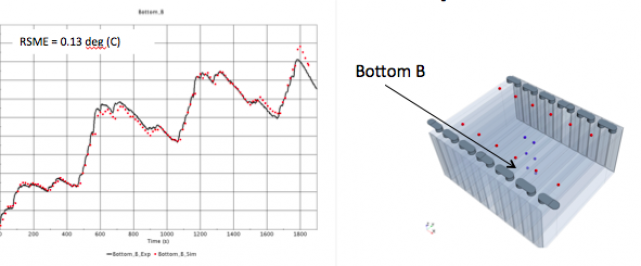

Left: Plot of temperature on the surface of a cell within the simulated module compared to an experimental measurement. Right: Position of the temperature sensors in the tested module.

The electrochemical and thermal model is applicable at the cell, module and pack levels of analysis – users can control the fidelity of the model depending on desired output and level of accuracy.

The project team used five cells from two different manufacturers, including stacked, cylindrical and prismatic wound electrodes, to validate the computational model using real-world drive cycles. They also added a database incorporating 12 contemporary electrolyte formulations, typical of those used in modern lithium-ion batteries, and created a calendar aging model, which works alongside the created cell performance models, preconditioning them to an “aged” stage.

Source: CD-adapco via Green Car Congress