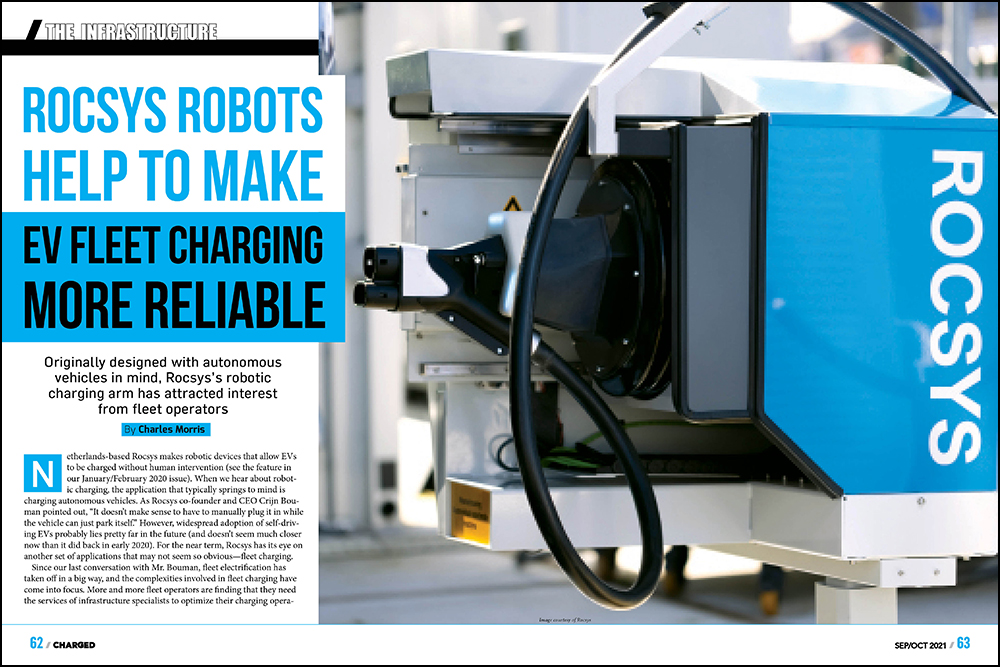

Originally designed with autonomous vehicles in mind, Rocsys’s robotic charging arm has attracted interest from fleet operators.

Netherlands-based Rocsys makes robotic devices that allow EVs to be charged without human intervention (see the feature in our January/February 2020 issue). When we hear about robotic charging, the application that typically springs to mind is charging autonomous vehicles. As Rocsys co-founder and CEO Crijn Bouman pointed out, “It doesn’t make sense to have to manually plug it in while the vehicle can just park itself.” However, widespread adoption of self-driving EVs probably lies pretty far in the future (and doesn’t seem much closer now than it did back in early 2020). For the near term, Rocsys has its eye on another set of applications that may not seem so obvious—fleet charging.

Since our last conversation with Mr. Bouman, fleet electrification has taken off in a big way, and the complexities involved in fleet charging have come into focus. More and more fleet operators are finding that they need the services of infrastructure specialists to optimize their charging operations. A new ecosystem of fleet charging service providers is emerging, in which Rocsys could claim a valuable niche.

The company is steadily signing up customers as it moves toward serial production. It’s been seeing increasing interest from US companies, so Rocsys recently opened an office in Portland, Oregon, a metro area where a lot of companies are already making the transition to electric transportation.

Charged reconnected with CEO Bouman, along with Senior Business Development Manager Erin Galiger, to get an update on Rocsys’s activities, and to learn more about why it makes sense to let robots do the charging, even if humans are doing the driving.

Crijn Bouman: Our mission is to power clean transportation by making charging autonomous. At the moment, our focus is mainly fleets—trucks, buses, yard tractors, etc. Longer-term, of course, we are also focused on autonomous vehicles [but] today the market is mainly fleets.

We are now supplying small quantities of product to customers, mainly big-vehicle OEMs in the professional fleet space, which are typically either at the OEM’s premises or at the end customer—one, two, three units, not complete fleets.

When Rocsys started, we thought our market would be mainly opportunity charging and automated vehicles, but we were getting a lot of requests for fleet charging—overnight charging, where we solve the reliability problem of charging connections.

We’re getting a lot of interest for—let’s say—a slightly different application than what we envisioned. When Rocsys started, we thought our market would be mainly opportunity charging and automated vehicles, but we were getting a lot of requests for fleet charging—overnight charging, where we solve the reliability problem of charging connections.

Charged: Could you walk me through the advantages for trucks, buses, and yard tractors of using your system for overnight charging? What kind of problems is it solving in each use case?

Crijn Bouman: Yeah. Of course there needs to be a reason why the driver can’t do the charging, right?

In some of the cases, like yard tractors, for example, they’re used at seaports, it’s an opportunity charging regime, and the driver is just not allowed to get out of the vehicle because it’s too dangerous—big harbor cranes driving around, etc. In mining, we have some customers that have autonomous mining vehicles, and of course it’s very logical.

In the big fleets, it’s more about reliability of plugging in. Drivers can do it, but they’re actually not very consistent in doing it. They forget it, and they find out the next morning it’s not charged. We have seen vehicles that are moved from one location to another during the night, somebody forgets to plug in, or they don’t plug in properly. Fleet owners have indicated that drivers can sometimes be careless, they leave the cable on the ground. Big truck comes, breaks the cable, and then the charger’s out of order for three days.

We were actually a bit surprised that this segment is so interested in our solution, but we see now it’s actually a majority of the customers. It’s basically: be more reliable than people. We also see that drivers are typically not really enthusiastic to take charging as part of their scope. We always say it’s a small job, but it’s a big responsibility—if something doesn’t work properly the next morning, everybody knows who forgot to plug in that bus.

Also, in some cases it’s triggered by unions. The drivers in bus operations, and also in seaports, their job is driving, not other stuff. It’s not part of their contract, and they have to be compensated extra if they have to take charging as part of their scope.

Also, high turnover of drivers. Every month there are new people starting, and every month there are people leaving. These people are like six months on the job, then they leave, and it’s a constant hassle for the fleet managers to make sure this is reliable.

It’s actually a big variety of cases, I would say. But in overnight charging, it’s mainly reliability. It’s making sure the operation becomes more predictable and reliable.

The majority of our customers now are actually more in these commercial fleets, so we decided to focus more on this. At the moment we are mainly in pilots with all kinds of large professional-vehicle OEMs, and beginning to develop a new design specially for these fleets.

Charged: How would a product specifically designed for this type of overnight fleet charging application differ from the one you originally envisioned?

Crijn Bouman: It will be more compact, and more cost-efficient in terms of price.

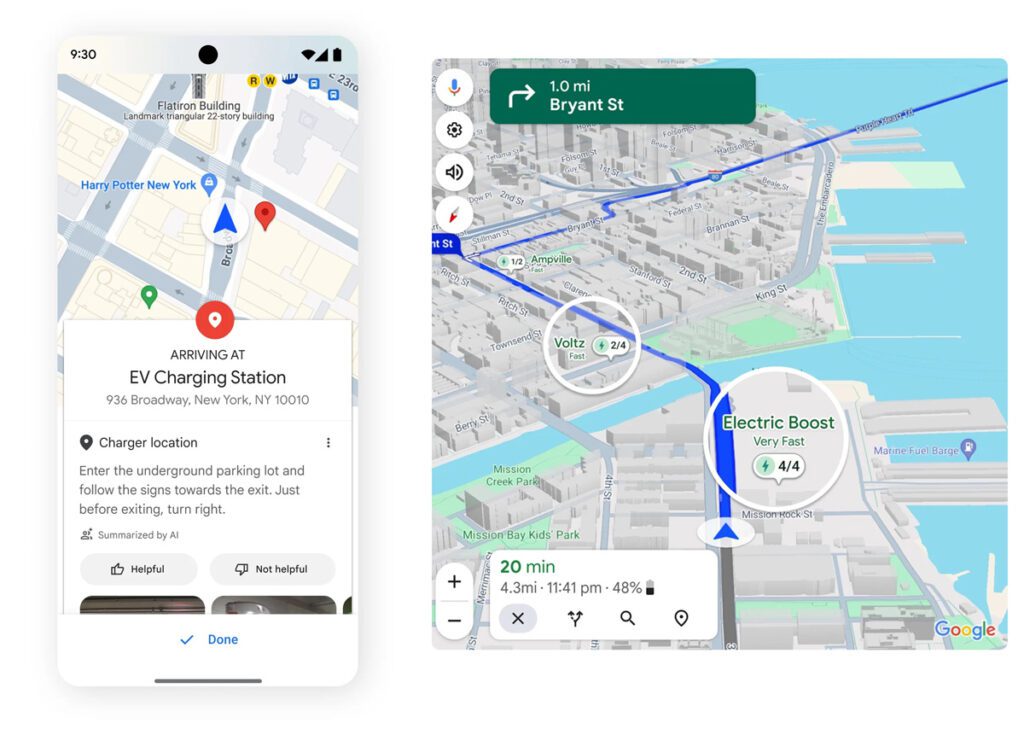

Erin Galiger: I think there’s also the pairing pieces, because opportunity charging is just a vehicle pulling up, and the robot sensing the port, seeing the port, and connecting. There’s a little bit more intelligence and fleet coordination in a depot setting where it’s not necessarily first in, first out, but there’s some thoughtfulness around which vehicles need to be charged first.

Crijn Bouman: We try to support our customers in achieving a higher throughput, or higher performance from their fleet, either by improving the reliability of the charging connection, or improving the throughput of a certain charging location, trying to serve as many vehicles as possible within a certain footprint and amount of charging equipment on the site.

Charged: Are your systems designed to work with any charging hardware?

Crijn Bouman:Yes. It’s basically mounting the CCS connector, or any other charging standard, to the robot with a specially-designed bracket, and then it’s an automated charger. There’s no integration with charger manufacturers. On the vehicle side, we basically need an automated charge port cover. That’s the only change on the vehicle side, because you want the charge port cover to open when it’s pulled up in front of the robots. We designed a special retrofit part for that, which can be used by commercial vehicle manufacturers.

Charged: So, you can retrofit that on many different types of vehicles?

Crijn Bouman: Yeah, exactly. For fleets, that’s the plan, and for automotive it’s about standardization. There is now an IEC and ISO standard, and hopefully soon, North American standards for robotic charging, in development. It started in January [2021], and it’s mainly about the sequence of automating the charge port cover, and the communication signal to synchronize this.

Not all vehicles today have an automated charge port cover, and in automotive, everything needs to be standardized—if it’s not standardized, it doesn’t scale.

Charged: Have you seen interest from the passenger OEMs?

Crijn Bouman: Yes, we have. At the moment our application with passenger OEMs is mainly in the R&D center, and in order to support development programs of self-driving vehicles. So, you could imagine that OEMs, which have very significant self-driving development efforts, are our customers.

Charged: On the fleet side, who do you foresee will be the customer? I would imagine it would be one of the many companies that are popping up to help people do their charging infrastructure for these large fleets, like In-Charge or AMPLY Power.

Crijn Bouman: They could be. Actually, for the US, we are investigating how the market works, because this category of companies, it’s not that big in Europe. In Europe at the moment, our customers are mainly the OEMs, who are selling it to the end customer together with the vehicle. But one of Erin’s many hats as Business Development Manager is to figure out the best model for the US. We had some talks with the fleet charging solution companies. I think it makes sense.

Erin Galiger: What I’ve seen in the market is, there are some companies that package a whole charging solution with the vehicle. I know companies such as Proterra and Daimler are really keen on having both the vehicle and also the charging solution, and making sure all that’s integrated to the end user. But I think for others, there might be more use of some type of integrator solution, so that they’re using multiple vehicle manufacturers and multiple charging manufacturers, bringing it all together.

Crijn Bouman: For us it’s quite strategic to work with the vehicle OEMs because in the end, for large projects, you often need the buy-in from the OEM, because the fleet operator will buy millions worth of vehicles and they will ask the OEM about the charging solution. Do you support it? Do you recommend it? So, for us, it’s important for them to get the buy-in from the OEMs that it works in a stable manner with their vehicles.

Charged: Are you still iterating on the hardware side, or have you found a solution that you think is ready for production once the industry is ready?

Crijn Bouman: Our current product is optimized for the opportunity charging cases, and the more industrial cases. At the moment we are supplying on the order of a dozen systems, or for pilots, and probably by the end of the year, beginning of [2022], we would be ready for larger projects. Also, it’s such a new application that it requires quite some learning curve for us on the customer side to understand how to apply the product in the best way. What kinds of customers actually make sense for this product? But in terms of product readiness, I would say early next year.

Charged: Can you walk me through the process of installing the arm, and how it works exactly?

Crijn Bouman: It uses computer vision. It can be installed next to any charging station, and the installation process is very simple. It’s four bolts in the ground, then there is a special bracket to connect the cable. Then there is commissioning, which is a one-time process, setting the software parameters, etc, for that application. That part is relatively simple. No special power requirements—it’s just 120 or 240 volts, so it’s really super-easy to install.

It uses computer vision. It can be installed next to any charging station, and the installation process is very simple. It’s four bolts in the ground, then there is a special bracket to connect the cable.

Also, for some of the pilot projects, we have a portable robot base, which is just a heavy metal structure, which you can move around for piloting. But the navigation of the robot works based on computer vision, and so it’s deep learning technology, AI. It’s trained to recognize the CCS (or other charging standard) inlet, so there is a basic level of training.

These are self-learning algorithms, so the more pictures you feed to the algorithm, the better it gets at the job. It has a certain preset, and when we go to a fleet customer, it’s then specifically trained for that customer. We take a couple hundred pictures, train the algorithm, and then it gets better and better over time. The computer vision has 3D detection and the robot has six degrees of freedom, allowing for the connector to be guided in regardless [of whether] the vehicle is parked at a small offset.

Charged: So a vehicle would park next to it, its automated door would open and then just detecting the plug would initiate the movement? Or is there some other communication?

Crijn Bouman: That depends per customer. In most customer cases now, they actually want the driver to trigger it, but it could also be automated like you just said. But with vehicles with drivers, often the customers prefer that the driver triggers it, because the driver then also has the job to secure that everything’s all right, and that it’s ready for charging.

Usually in the overnight case, you want to make sure that the vehicle is on the handbrake, or that the drivetrain is disabled, when the robot moves towards the vehicle. So, when the vehicle’s on the handbrake, then the robot is triggered to approach. That’s one way of doing it.

Charged: On some passenger vehicles there’s a little plastic flap that covers the DC charging prongs in the CCS socket. I imagine you just remove that on commercial vehicles?

Crijn Bouman: For commercial vehicles it’s easy to solve, because it’s integrated into the charge port cover. But that question is also part of the standards—to agree on how to deal with the additional cover. Actually, the question is: why is it actually needed? Tesla doesn’t have it. It seems to be something which just evolved—until now, we haven’t found any OEM who has a clear reason why. On the one hand, its intention is to protect the socket better. But if this is open and then it’s raining and there is sand on it and you close it, it’s actually making the situation worse. That’s the question, which is now in standardization.

Charged: We talk a lot to companies that are working on fleet charging solutions, and they talk about the same things all the time, how they need third parties to help manage all these charging challenges, because the fleet managers just don’t consider it.

Crijn Bouman: It’s really a headache for them. Also, what we have seen in Europe is that the first pilot starts with five or ten vehicles, and you have very motivated drivers, everybody’s happy, but then it’s rolled out in a complete fleet. If you have 100 vehicles, and three are not charged, it sounds like a small problem. But for a fleet operator, three out of 100 EVs not charged is really a big problem because the whole schedule is messed up.

This article appeared in Issue 57 – Sept/Oct 2021 – Subscribe now.