A team from the University of Texas at Dallas has teamed up with Texas Instruments to demonstrate silicon’s ability to harvest energy from heat while still remaining mass-producible.

“In a general sense, waste heat is everywhere: the heat your car engine generates, for example,” said Mark Lee, head of UT Dallas’s Department of Physics and author of the report. “That heat normally dissipates. If you have a steady temperature difference – even a small one – then you can harvest some heat into electricity to run your electronics.”

Lee said the primary hurdles for widespread thermoelectric harvesting have been efficiency and cost. Since the 1950s, researchers have known silicon to be a poor thermoelectric material in its bulk, crystalline form. But in 2008, new research indicated that silicon performed much better as a nanowire, which is a filament-like shape with two of its three dimensions less than 100 nanometers. (For comparison, a sheet of paper is about 100,000 nanometers thick.)

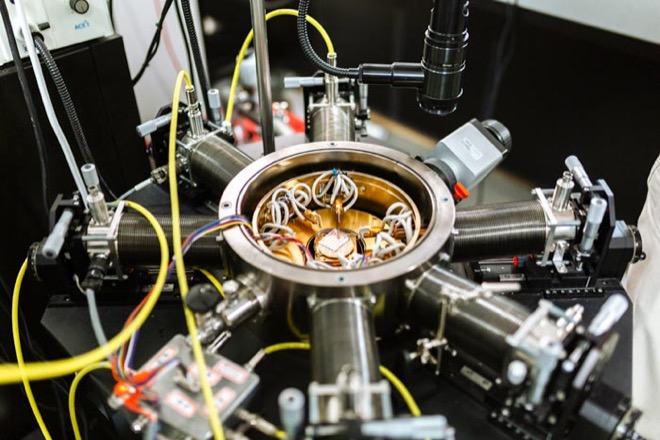

“In the decade since those experiments, however, efforts to make a useful silicon thermoelectric generator haven’t succeeded,” Lee said. One barrier is that the nanowire is too small to be compatible with chip-manufacturing processes. To overcome this, Lee and his team relied on “nanoblades” – only 80 nanometers thick but more than eight times that in width. While that is still much thinner than a sheet of paper, it’s compatible with chip-manufacturing rules.

Lee noted that the nanoblade shape loses some thermoelectric ability relative to the nanowire. “However, using many at once can generate about as much power as the best exotic materials, with the same area and temperature difference.”

The team’s circuit-design solution combined an understanding of nanoscale physics with engineering principles. One key realization was that some previous attempts failed because too much material was used.

“When you use too much silicon, the temperature differential that feeds the generation drops. Too much waste heat is used, and, as that hot-to-cold margin drops, you can’t generate as much thermoelectric power. There is a sweet spot that, with our nanoblades, we’re much closer to finding than anyone else.”