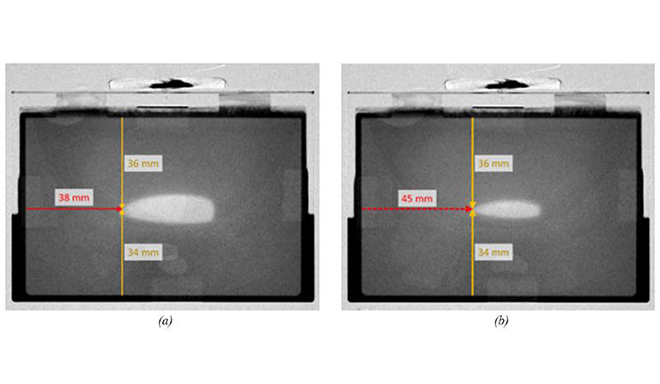

Researchers from Bosch, the Technical University of Munich, and the University of Erlangen-Nuremberg are using neutron imaging to analyze the filling of lithium-ion batteries with electrolytes. Since very few neutrons are absorbed by the metal battery housing, they are ideal for analyzing batteries.

In “Visualization of electrolyte filling process and influence of vacuum during filling for hard case prismatic lithium ion cells by neutron imaging to optimize the production process,” published in the Journal of Power Sources, W.J. Weydanz and colleagues explain how they found that electrodes are wetted twice as fast when the filling process is performed under a vacuum. Their tests showed that in a vacuum, the electrodes were wetted completely in just over 50 minutes, while under normal pressure, it took around 100 minutes. This occurs because the liquid spreads evenly in the battery cell from all four sides, from the outside in.

These findings have the potential to greatly reduce battery manufacturing times, as one of the most critical and time-consuming processes in battery production is the filling of lithium cells with electrolyte fluid. Manufacturers often fill the lithium cells in a vacuum, monitoring the process indirectly using resistance measurements. “To make sure that all the pores of the electrodes are filled with the electrolyte, manufacturers build in large safety margins,” says Bosch developer Dr. Wolfgang Weydanz. “That costs time and money.”

Source: TUM News via Green Car Congress