Electronics giant Honeywell has created a number of solutions to improve the safety of lithium-ion batteries, for EV drivers, first responders and workers involved in battery production.

In rare cases, Li-ion batteries can undergo thermal runaway incidents, causing intense and prolonged electrical fires. Workers assembling batteries face risks such as hand injuries and exposure to chemical hazards. As EVs and batteries proliferate, companies need to maintain a focus on safety.

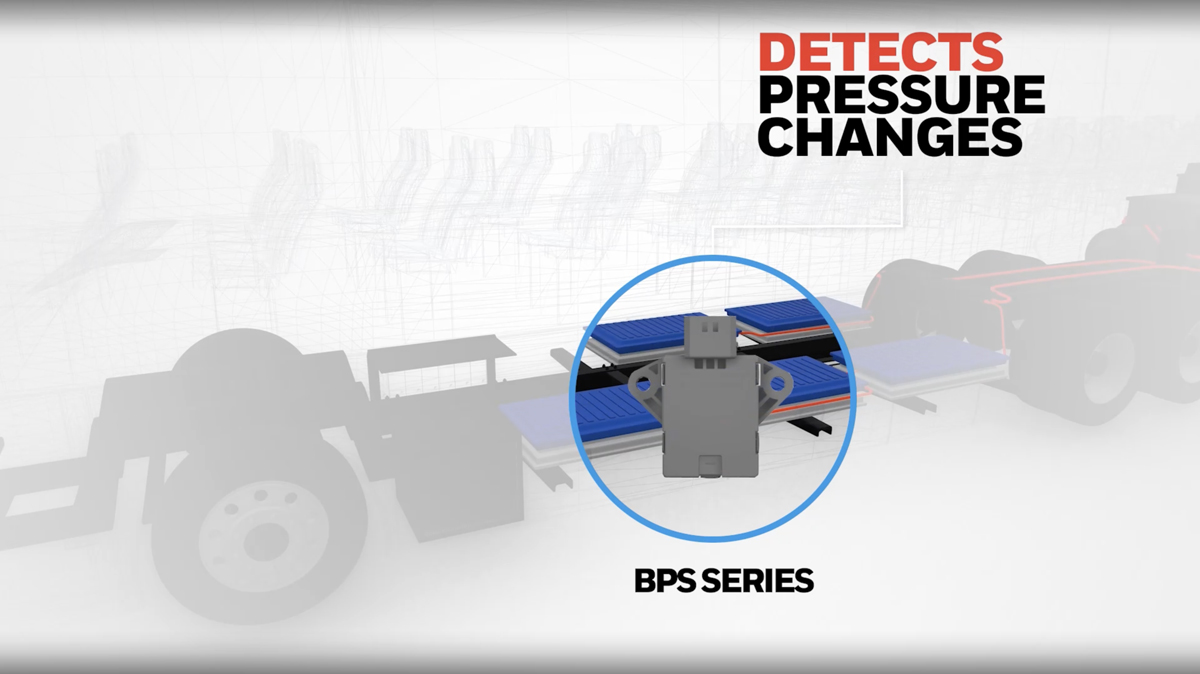

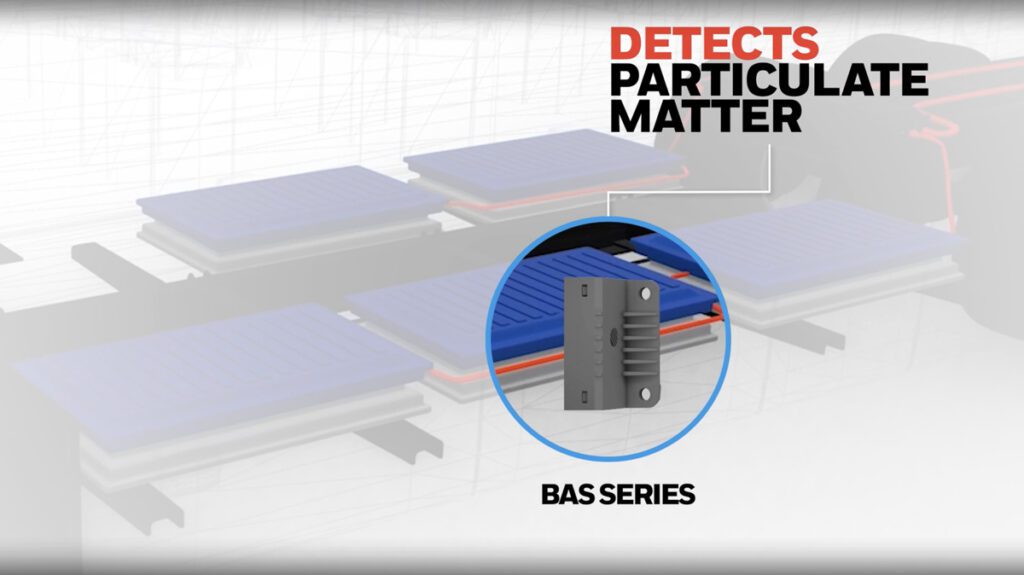

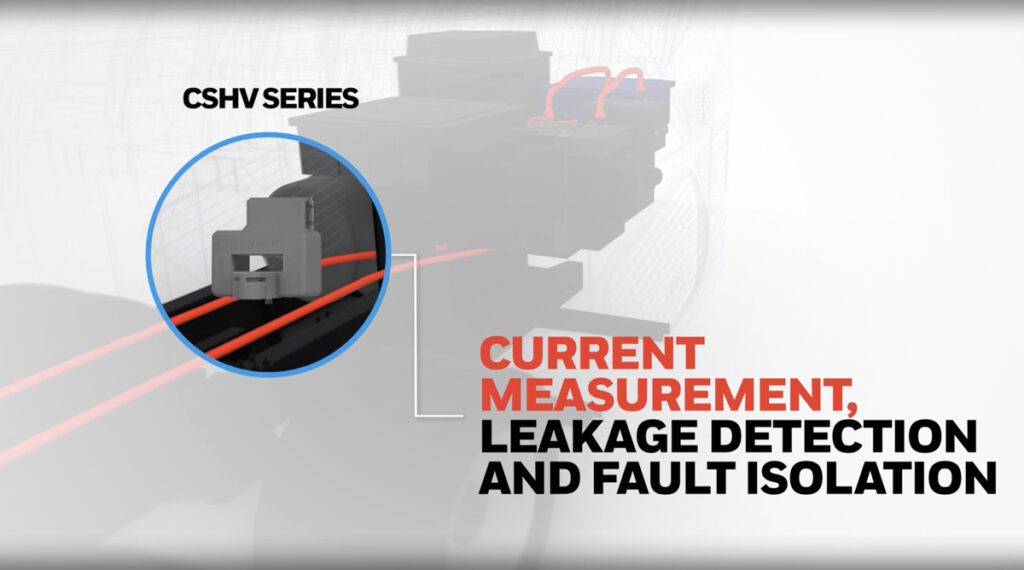

Honeywell’s battery safety sensors, integrated into EV battery packs, are designed to detect the signs of impending thermal runaway events, allowing passengers to be notified of the risks. Through a strategic alliance with Nexceris, developer of the cleverly-named Li-ion Tamer gas detection solutions, Honeywell is developing sensors to detect earlier thermal runaway indicators in EV batteries.

While sensors can allow for early detection of battery malfunctions, they cannot yet prevent them altogether. When a Li-ion battery fire does occur, first responders must be properly equipped to fight these fast-burning, incredibly hot flames. Honeywell provides fire and emergency services departments with the gear needed to combat battery fires.

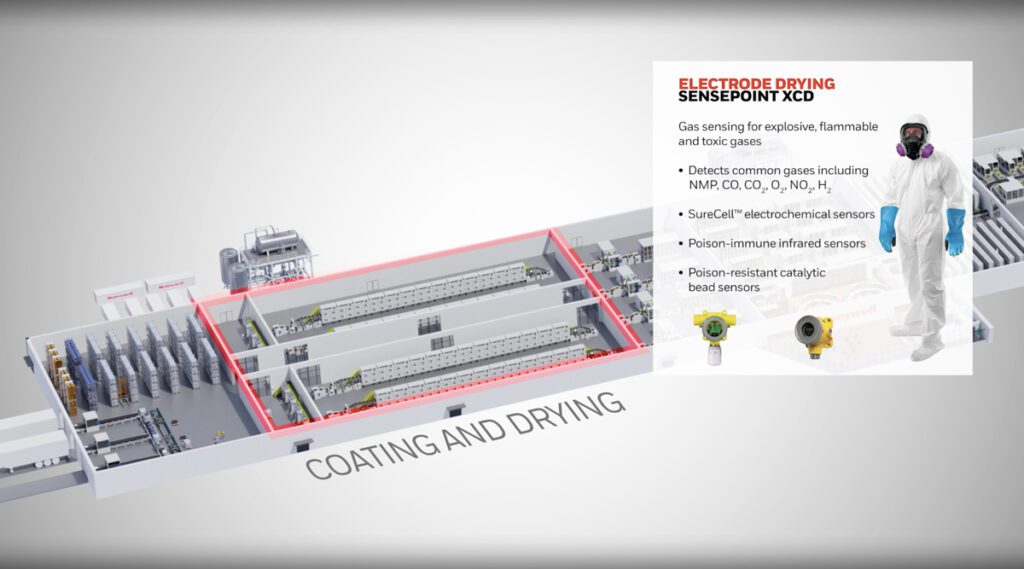

The battery assembly process poses risks of hand and eye injuries, exposure to toxic and flammable chemicals, electrocution, and arc flash, which occurs when electrical current leaves its intended path and arcs to the ground.

To help keep workers safe, Honeywell offers comprehensive personal protective equipment (PPE), electrical safety gear and gas detection technology for high-risk areas such as electrode mixing, coating, drying and cell finishing.

“Electric vehicles are pivotal for a sustainable future of transportation,” said Victor Verissimo, General Manager of Electrification for Honeywell Sensing and Safety Technologies. “However, sustainability can’t compromise safety. Honeywell’s portfolio of solutions helps make the production and operation of EVs safer for all involved.”

Source: Honeywell