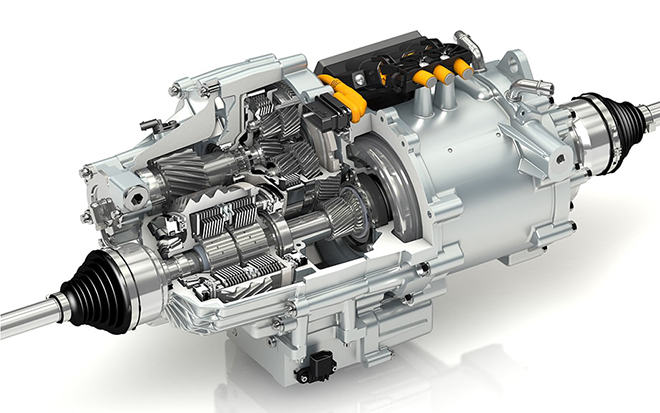

GKN Driveline’s eAxles integrate an electric motor and a two-speed transmission in a single compact unit. This not only makes it easier to fit an eDrive unit within a vehicle chassis, but also improves efficiency on vehicle assembly lines.

GKN supplies front eAxles for the Porsche 918 Spyder and BMW i8, as well as rear eAxles for the Volvo XC90 T8 Twin Engine and BMW 2 Series Active Tourer.

GKN’s newest offering, the eTwinsterX, takes compactness to a new level. The company says it’s significantly smaller than other systems with equivalent power outputs, and is adaptable to any vehicle type, from city EVs to plug-in hybrid SUVs, with single-axle or all-wheel drivetrains. The eTwinsterX is also the first of the company’s eAxle line to offer full off-road capabilities.

GKN’s eTwinsterX system can be used either for the primary drive in fully electric vehicles, or for the secondary drive on plug-in hybrid vehicles, creating a split-axle driveline. It can be integrated into existing vehicle platforms, enabling bolt-on AWD hybridization without major modifications to the vehicle design.

Conventional wisdom is that EVs don’t need a multispeed transmission, but according to GKN, a two-speed transmission enables a better balance of acceleration and top speed. Multi-speed transmissions enable EVs to deliver better launch performance, using the lower gear, and more efficient high-speed driving, using the higher gear. Torque vectoring provides intelligent control of vehicle dynamics by managing the distribution of torque to individual wheels.

Plug-in hybrid drivelines typically involve adding an electrified element to the rear axle, which adds weight and can increase the vehicle’s tendency to understeer. The eTwinsterX’s precision torque distribution to the rear wheels is designed to mitigate the change in mass, delivering greater agility and more engaging driving characteristics.

eTwinsterX can also produce a negative torque effect to slow the vehicle, and provides a limited-slip differential function. When a dynamic imbalance is detected across an axle, the system sends more power to the wheel with the higher traction. When slowing down, the electrified Twinster system can stabilize the vehicle and recover kinetic energy at the same time.

“eTwinsterX applies principles from our GKN driveline portfolio in a single state-of-the-art electrified system,” said Peter Moelgg, CEO of GKN Driveline’s AWD and eDrive business. “GKN is unique in being able to deliver an integrated e-motor, two-speed electrified transmission and torque vectoring within a complete eAxle system. GKN’s capability as a complete systems integration partner will also allow us to calibrate eTwinsterX to deliver fully brand-aligned experiences for our OEM customers.”

SEE ALSO: Electric torque vectoring

Source: GKN Driveline