Widescale commercial vehicle electrification requires intelligent systems engineering

Electrification continues to gain traction throughout the commercial vehicle industry. Driven primarily by rapidly falling battery costs, and thus lower total operating costs, vehicle makers are racing to electrify existing models and launch all new electric vehicles. Tightening emissions regulations and corporate social responsibility targets also factor into the rise in electrification’s viability. Since commercial vehicles are a substantial source of greenhouse gas emission, they have become a priority segment for electrification – a trend spurred by diesel bans and zero-emission regulations announced inside major cities around the world.

As a result, the market value of industrial and commercial electric vehicles (EVs) is expected to increase considerably in the coming years. According to a recent Frost & Sullivan report, the electrification of the medium- and heavy-duty truck market is expected to grow by 48 percent by volume compounded annually from 2017 to 2025. In just the next six years, 11 percent of this entire market is expected to become electrified. If battery costs continue to drop at rates ahead of many projections, substantially larger adoption rates may be possible. Despite the projected EV growth, commercial vehicle manufacturers still face challenges to electrify fleets.

One significant barrier slowing the pace of commercial vehicle electrification, especially for large Class 6, 7, and 8 trucks, is the lack of viable electric powertrain alternatives. Although cost effectiveness and packaging remain a concern, the performance of many commercial vehicle e-powertrains currently falls below the capabilities of conventional diesel powertrains.

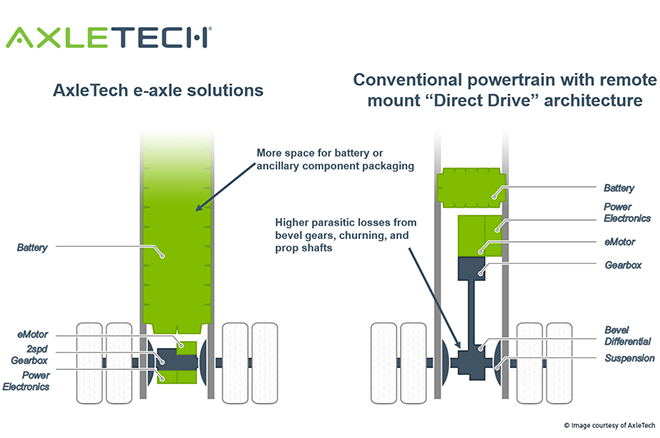

Early solutions have involved replacing the heavy-duty truck engine with a single, large electric motor and multi-speed gearbox. This configuration is referred to as a “direct drive” solution because it follows the traditional longitudinal drivetrain platform. However, this direct drive approach has noticeable drawbacks, including poor packaging, efficiency, cost, and compatibility of the major components. While this approach is certainly easier to implement, the lack of systems engineering experience often equates to performance and packaging concessions that fall below user expectations.

More recently, many companies have sought to engineer around these deficits by launching new commercial EV powertrains with very specialized configurations. Some of these solutions offer superior performance to diesel, but they contain varying degrees of customized chassis, suspensions, and e-powertrains that raise concerns of long-term supportability and cost. Consequently, successful Tier 1 suppliers must take a different approach to develop optimized e-powertrains that are efficient, reliable, and easy to implement and maintain. This systems-engineered approach will drive wide scale electrification of commercial vehicles.

Introducing an e-axle system for commercial vehicles

AxleTech has created a highly integrated e-axle for medium- and heavy-duty commercial truck applications. By fully integrating the motors and two-speed transmission into the axle, AxleTech’s solution provides the highest performance and efficiency in the smallest packaging, while fitting within the existing chassis, suspension, and wheel end envelope. With these crucial benefits, this EV system lowers the total cost of ownership, decreases the required battery size, and improves the regeneration capabilities versus a diesel or unintegrated e-powertrain. The number of moving parts in the AxleTech system also is much less than traditional drivetrains, so maintenance costs are lower.

Employing its unique approach, AxleTech will unveil its first product offering in early 2019. This product has been designed to exceed the power requirements of current diesels and fit in the same package space, on top of providing optimized efficiency and serviceability that is required of existing commercial trucks. Upon its release, the system will be the most powerful electric heavy-duty powertrain from a Tier 1 supplier, surpassing the performance of diesel and all other EV systems.

Power-dense, efficient performance

AxleTech’s commercial vehicle e-powertrain is expected to lead the industry in power and efficiency. The system features two high-speed electric motors, a multi-speed transmission, and eliminates the need for additional driveshafts and support structures. As a single axle, it meets, and in some cases exceeds, the power and capabilities of a 15-liter diesel engine, generating much more power per axle than the next best e-powertrain offering. While other Tier 1 solutions require two e-axles in a 6×4 configuration for Class 8, AxleTech’s solution can provide full Class 8 performance in 4×2 or 6×2 configurations. As a 6×4 tandem set, the solution will be the most powerful Class 8 powertrain in the world.

To optimize cost and performance for different customer and application demands, the system can be configured with one or two motors per axle, allowing customers to customize the desired performance level. For example, a 4×2 Class 6 e-axle will match diesel performance with a single motor, while a Class 8 customer can order a 6×4 with two motors on one e-axle and a single motor on the other. This flexibility is critical for cost since motors and inverters represent a large percentage of overall e-axle cost.

Unlike many of the current EV powertrains that use single-speeds that must trade off gradeability for top speed, AxleTech’s integrated multi-speed transmission helps ensure that there are no concessions in performance. Having two speeds also increases efficiency by allowing the electric motor to run in its most efficient operating zones. Compared to a diesel powertrain, the integrated e-powertrain is much more efficient.

Beyond these performance metrics, AxleTech’s e-powertrain provides the needed technical advantages to ease fleet operators’ transition to electric powertrains.

Compact packaging with standard parts

To support mass adoption of the technology, AxleTech designed its commercial vehicle e-axle to fit into the typical Class 8 truck chassis and suspension used by almost every global commercial vehicle manufacturer. The new EV system has a packaging size comparable to that of a standard tandem axle “between the wheels.” This allows for easy integration of the system into existing vehicle platforms as well as frees up space for the battery and ancillary components. Additionally, the company incorporated many industry standard parts and suspension locations, including mounting points, to make assembling the system into the vehicle via traditional manufacturing processes possible.

Ultimate flexibility

With many paths to electrification being forged, AxleTech strived to make its e-powertrain a fully flexible solution. The new technology is agnostic of the electrical power source – battery, fuel cell or range extender systems – and only requires power cables, cooling lines, and a control cable to connect to the vehicle. Furthermore, AxleTech designed its solution from the start to be modular, allowing for high part commonality between its Class 8 and Class 6 e-axles.

Enhanced driver safety and productivity

Adding to its performance and technical advantages, the new e-powertrain is beneficial to end users. Trucks will accelerate quicker, increasing vehicle safety by assisting drivers in more easily merging with traffic and keeping pace with lighter vehicles. There also is the option of one-pedal driving to improve the driving experience by reducing the risk of driver fatigue. Overall, the advanced solution will boost a truck’s ability to get places safer and faster, which will raise the productivity of drivers and fleet owners.

Looking ahead, AxleTech’s highly integrated e-powertrain technology has tremendous potential for additional applications in other heavy-duty commercial vehicles. The company is exploring future iterations of the product in vehicles with different power level requirements, such as school buses and trucks in Europe and Asia – which represent a bulk of new EV growth.

Contact AxleTech more information on its electric vehicle systems.