Groundbreaking glue: New results show as much as 44% core loss reductions for the same steel and lamination thickness.

Many design decisions in the EV industry are still driven by range. Engineers remain focused on delivering system efficiency improvements, because it directly translates into delivering more range without increasing the size and cost of the battery pack.

In the field of electric motor design, automakers are continually pushing suppliers to achieve the next level of torque, speed and efficiency. To get there, engineers are incorporating new steel formulations, manufacturing techniques and the latest and greatest motor designs and topologies.

At the heart of the motor are soft magnetic materials called electrical steels. They’re typically manufactured by steel mills in cold-rolled strips, then stamped into precisely-shaped thin laminations, which are stacked together to form the stator and rotor of a motor.

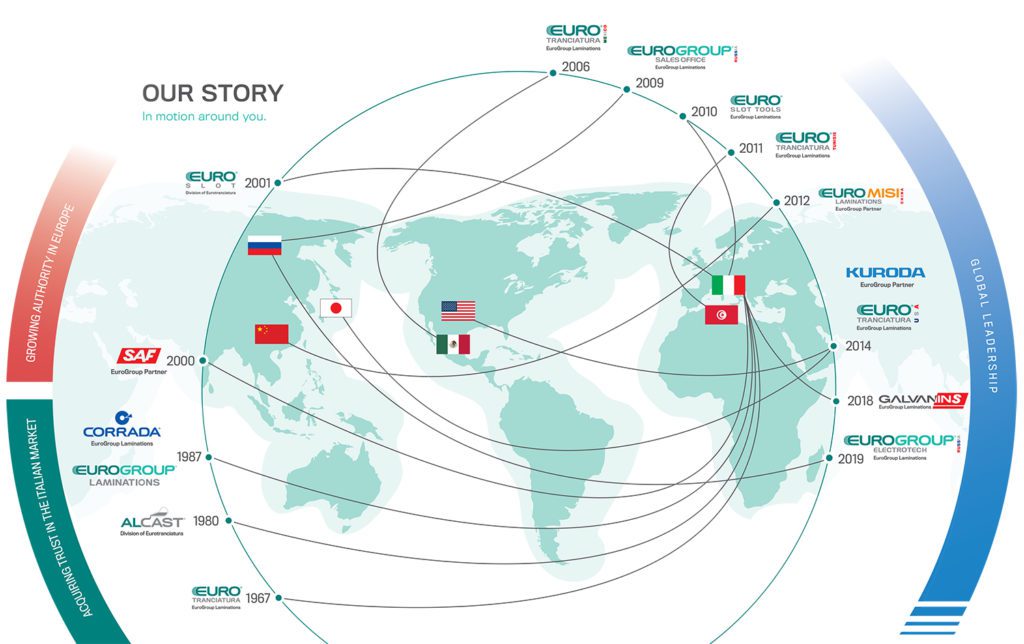

EuroGroup Laminations is a company that focuses on the production of high-tech stators and rotors to power a variety of applications, including the booming EV industry. The company works with all the major automakers and has a truly global reach, with facilities across the globe.

One of the group’s partners in Japan, Kuroda Precision Industries, has developed a ground-breaking system using glue to firmly fasten laminations together, making it possible to automatically stack the metal sheets inside the die and maintain excellent magnetic properties.

The new technique, called GlueFastec, is ideal for working with very thin lamination steel.

In the EV industry, there is a trend toward using thinner and thinner laminations, because the thinner you make the electrical steel, the better the magnetic characteristics of the core pack. However, these tightening specs have presented significant engineering challenges in manufacturing, as high-speed stamping and stacking of thin materials required process innovation.

R&D undertaking

Since 2016, Eurotranciatura México – another of the company’s subsidiaries, located in Santa Rosa Jáuregui, Mexico – has been charged with the study and development of Kuroda’s GlueFastec to decrease losses in electric motors across a range of applications.

EuroGroup Laminations funded unique R&D laboratories in its Queretaro, Mexico, facility devoted to measuring core loss, with physical test benches and proprietary simulation programs.

Core loss in a magnetic core is associated with two factors: hysteresis loss due to iron grain damage and mechanical stress; and eddy current losses (also called Foucault current) due to short circuits between laminations that oppose themselves to magnetic flow.

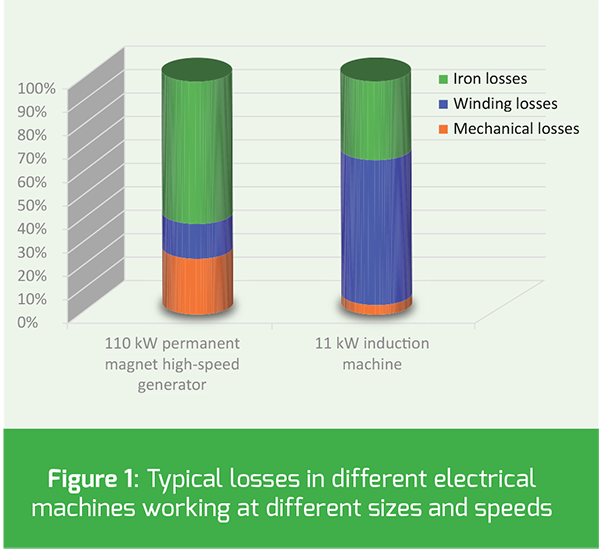

Some published research has shown that “iron loss accounts for 34% of total losses in induction motors and up to 59% of total losses in high-speed permanent magnet motors,” as Andreas Krings writes in a 2014 doctoral thesis. That research, completed at the KTH School of Electrical Engineering in Stockholm, showed that “at higher speeds, iron losses due to the fast-changing magnetic fields become the major loss component.”

These findings underline the importance of the EuroGroup initiative, and the company says its R&D effort has paid off with a new generation of electric motor designs, both in the fast-growing EV sector and in the traditional industrial motor industry.

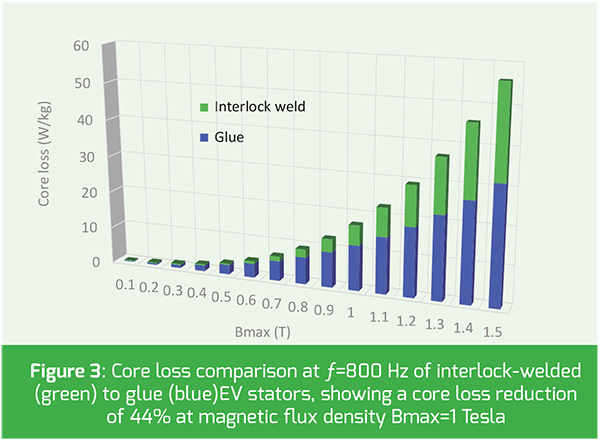

The R&D project’s first results, obtained in 2017, demonstrated a 15% decrease in core loss when an interlock core stacking method (one common production technique) is replaced with GlueFastec technology.

The latest results, soon to be published in a peer-reviewed journal, compare three production methods: interlock versus glue in EV stators; cleated versus glue in industrial stators; and interlock-welded versus glue in EV stators. The work reveals improvements, dependent on design, ranging from 15% to 44% core loss reductions for the same steel and lamination thickness.

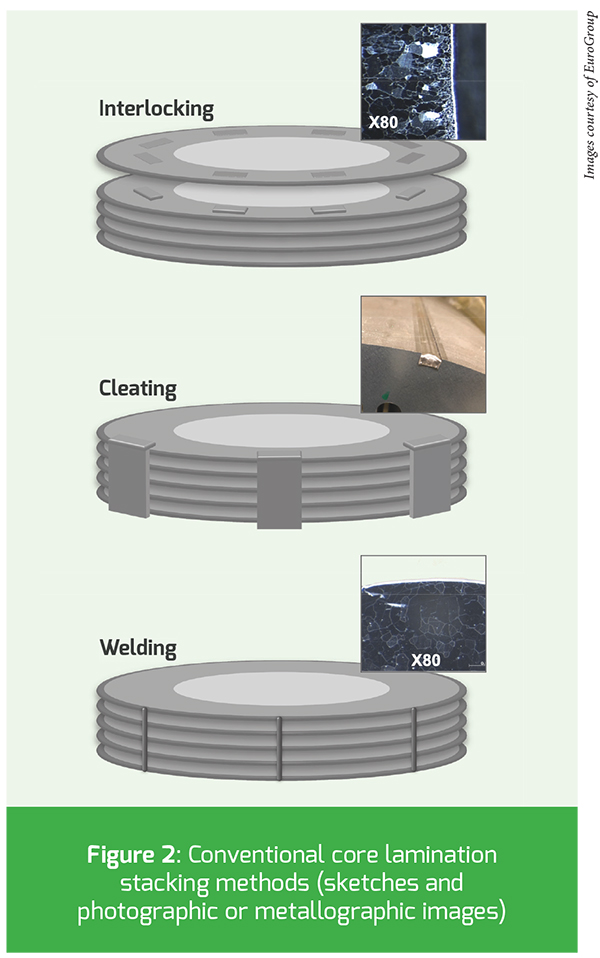

Figure 2 shows three conventional stacking methods that hold steel laminations together: interlocking, cleating and welding. Metallographic images reveal iron grain damage as well as reduction in size and homogeneity, while inter lamina contacts (short circuits) are shown in sketches and photography.

Reducing mechanical stress while maintaining high-speed assembly

EuroGroup says that GlueFastec technology can further improve motor efficiency as it allows high-speed stamping and assembly of thin materials, without adding further mechanical stress.

“Other glue techniques for an iron core have been around for many years,” Mario Villalon, Technological Innovation Director for Eurotranciatura México, told Charged. “However, one of the big innovations of GlueFastec is the cure time. Other glues take a very long time to cure. They need to be placed in an oven and cured for hours. The key to our technology is that it cures so fast that you can integrate it into the blanking process.”

EuroGroup explains that, unlike traditional gluing processes, which are inconsistent with mass production of electrical machines, GlueFastec adhesive is applied in the blanking process and cures at room temperature in less than 3 minutes, with sufficient adhesion to be handled within the blanking process.

This process is proving to be ideal for very thin laminations, because the glue can bond stacks together without deforming the delicate stampings of electric steel. “In other processes that are traditionally used for core manufacturing, mechanical fixtures are used for stacking methods that hold the laminations together,” explained Villalon. “Those methods will stress the lamination in a mechanical sense. So when the laminations are too thin, you start to see deformations that you will not be able to control. But using this new glue and stacking method, you never stress the lamination – that’s a big advantage of using it.”

The company’s research shows that consistency of dimensional accuracy is improved, and in addition to creating an insulating layer, which contributes to significantly decreasing magnetic losses, GlueFastec was found to reduce acoustic noise by up to 5 times when compared to interlocking, as well as reducing vibration and increasing water resistance.

Figure 3 shows a typical result obtained when the core loss of interlock-welded versus glued EV stators was compared at a frequency of 800 Hz and magnetic density of 1 Tesla.

Real-world implications

With the global EV market expected to reach $912 billion by 2026 (according to Polaris Market Research), these efficiency gains could translate into a great business. EuroGroup says every automaker that is producing EVs is keen to learn more about GlueFastec, because EV designers could use the improvements to increase EV range, use fewer batteries for the same range, or increase vehicle performance.

Outside the EV industry, EuroGroup is also optimistic about the ability for GlueFastec to increase efficiency and lower power consumption for consumer products, aid industrial motors in meeting increasing efficiency standards, and offer motor designers the ability to achieve the same performance while using lower-grade steels.

EuroGroup innovation teams as part of the customer’s design team.

Electric drivetrain designers must address many parameters, including electrical efficiency, noise, vibration and mechanical integrity. EuroGroup says that the inherent concept of GlueFastec is ideally suited to help meet all of those demands.

To support its global partners, the company has developed a multi-discipline systemic approach to clarify the benefits of the GlueFastec core’s magnetic efficiency on a case-by-case basis.

“We spent the last year sharing the research results with our partners and customers. The concept of GlueFastec when employed in the original design concept has benefits not only associated with core loss,” said Villalon. “Now we’re working very hard to employ it in new designs and production. We’ve already won some very important contracts with GlueFastec, and we’re moving very fast.”

The company has established state-of-the-art laboratories to allow new electric machine designs to take advantage of core loss improvement. The company’s worldwide network is using a systemic approach to produce more efficient magnetic iron cores in one single process step, automatically, and fully integrated with industry 4.0 connectivity.

This article appeared in Charged Issue 45 – September/October 2019 – Subscribe now.