Researchers from Ohio State University have designed a thin plastic membrane that could improve the charging speed of current batteries, and possibly enable a new type of battery as well.

In a study published in the journal Energy & Environmental Science, assistant professor Vishnu-Baba Sundaresan and doctoral student Travis Hery argue that current battery designs have hit a performance limit, and are unable to add more than 0.4 miles of range per minute of charging. They believe that their new membrane technology may be the only way to exceed that limit, short of developing an entirely new category of battery electrodes.

“Research over the last 50-plus years has focused on advancing the chemistry of battery electrodes to increase capacity,” Sundaresan said. “We’ve done that, but the increase in capacity has come at the cost of robustness and the ability to rapidly charge and discharge batteries. Electric vehicle design is mature enough now that we know the limit they’re reaching is because of the chemistry of lithium-ion batteries.”

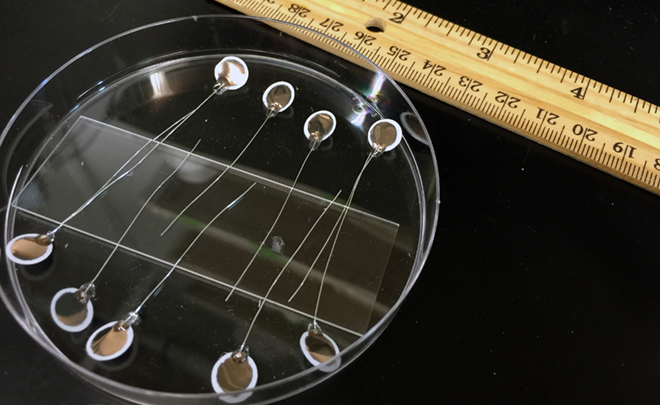

Li-ion batteries already have membrane separators that physically separate the anode and the cathode, but current membranes can’t completely prevent charge from leaking. An internal chemical reaction called self-discharge causes a gradual power drain or, in the worst-case scenario, a phenomenon called thermal runaway that can cause a battery pack to overheat and catch fire.

Sundaresan and Hery believe their membrane, when used with a specially designed electronic control unit, can shut down charge transport and prevent thermal runaway before it starts.

While the researchers have proven that the membrane works with conventional batteries, their ultimate goal is to use it as the basis for what they call a redox transistor battery – a new type of redox flow battery, in which a liquid electrolyte is pumped from anode to cathode to generate power (the company nanoFlowcell and a team at Pacific Northwest National Laboratory have both done work on flow batteries).

“For everyday commuting, the electrolyte can be simply regenerated by plugging it into a power outlet overnight or while parked at the garage,” Sundaresan explains. “For long road trips, you could empty out the used electrolyte and refill the battery to get the kind of long driving range we are accustomed to with internal combustion engines.”

Source: Ohio State University