Canada’s CapTherm Systems’ multiphase cooling technology could take the heat off of EV batteries and charging stations more efficiently, taking up less space using fewer materials while improving longevity and performance. Charged takes an early peek at this innovation before it goes commercial next year.

If you’ve never dropped your smartphone 10 feet onto pavement, left it in a cab, or witnessed it being accidentally knocked into a hotel room toilet bowl, you may still have the utmost faith in the genius of those ubiquitous uber-gadgets. But if you have seen the world grind down to slow motion as your expensive holder of relevant personal information is about to be submerged in water without anything you can do to stop it, you may have developed a semi-healthy case of phone paranoia.

Such was not the case when Philipp Fuhrmann, Co-Founder and COO of the early-stage Canadian company CapTherm Systems, willfully dunked his iPhone into the proprietary coolant fluid the company developed for its multiphase electronics cooling system.

“Our machinist then called him while the iPhone was submerged, and it was still fine,” said Timo Minx, Co-Founder and CEO of CapTherm. Minx is also the inventor of the company’s multiphase, liquid-to-vapor cooling technology. “In case of a leak,” he said, “our fluid doesn’t harm electronics equipment, because it’s non-conductive.”

Great! So what is this liquid, and can we use it in the aquarium that sits next to all the remote controls? “I’m very hesitant to tell,” Minx said. “It’s a customized formulation – it’s nothing off the shelf.”

What CapTherm more than happily tells us involves its debut of a commercialized multiphase cooling system planned for a launch at either CES in Las Vegas in January 2014, or at CeBit in Hanover, Germany next March. CapTherm will initially launch its systems in the IT space, followed by solutions for electric vehicles, EV charging stations and many other industries once the technology gains traction.

Vapor trails

Water and liquid cooling of electronics have been gaining in popularity over the tried and true heat sinks-and-fans method of air cooling. “Even in the IT world and the data center world, the unthinkable is happening right now,” Minx said. “People are actually pumping water into their server racks and into their servers – extracting the heat from the electronics components with water, simply because it is so vastly superior to air cooling. However, water cooling is not necessarily well-suited for electronics equipment because of the inherent problem: What happens in case of a leak? Also, water cooling requires the addition of a pump, a mechanical component that can fail over time.”

CapTherm’s multiphase cooling of electronic components (or batteries) as it relates to EVs, alleviates the danger of leakage by using its nonconductive fluid, but there are other advantages to multiphase cooling over water cooling.

“The primary difference is that we actually change the phase, so we boil the liquid off,” Minx said. “We go from a liquid phase to a vapor phase and condense it back in a condenser/radiator-like heat exchanger, where it changes back from vapor to gas. It’s very similar to your air conditioner or fridge. However, we do not utilize a compressor, so we’re not able to drop below ambient temperature. We can move heat without using any electricity. The energy required to initiate the process actually comes from the electronic component that gets hot in the first place. We’re really using waste energy to drive the system. Another big advantage is multiphase shows vastly better performance.”

Minx also cites greater volumetric efficiency: multiphase cooling is about 30 percent more space-effective than existing systems with the same performance. “We can make it smaller, lighter, and utilize less air flow,” he said. “It gives you all the advantages and more that liquid cooling gives you over air cooling with none of the drawbacks that liquid cooling currently has. For example, our systems that we designed and built in-house are all metallurgically sound, metal to metal connections.”

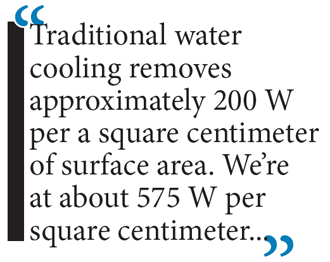

This multiphase cooling approach differs somewhat from heat pipe technology, which was invented in 1962 and is used in computers, HVAC, and other systems. “A heat pipe effectively utilizes the vapor phase change process on the inside,” Minx said, “but it is a very crude approach. Heat-pipe cooling doesn’t utilize the concept in a fashion that is efficient enough to really offer a competitor to liquid cooling. Actually, water cooling is more efficient than heat-pipe cooling. On the other hand, the way we’re putting the system together, we beat liquid cooling by a considerable margin.”

To help quantify that margin, CapTherm tests its units with a mass spectrometer that goes to 1×10-11 cc/sec/atm. “To put that in perspective,” Minx said, “we can detect leaks that equal one sugar cube of helium gas over 3,000 years. That’s something that no water cooling system could compete with or even come close to.”

The system also should operate at a wide range of temperature and pressure conditions. Minx gave -80 to 250 degrees Fahrenheit as the temperature range. As for pressure, Minx said, “As long as there’s fluid in the system, the pressure is dictated by temperature. As it gets hotter, pressure increases. If it gets colder, pressure decreases. Traditionally we can run these systems anywhere from vacuum conditions to 100-600 psi, depending on what fluid we use.”

Entry strategy

For Minx, CapTherm represents a revisiting of his past in more ways than one. His multiphase cooling innovations are a fulfillment of a previous mission that was cut short when he worked at Calgary, Alberta’s Cool IT Systems, where products under his direct management won three CES Innovation and Design awards for liquid cooling products. But it’s also a reunion with childhood friend Fuhrmann. Born in the same German hospital, Minx and Fuhrmann attended the same schools through the high-school level, and then met up again by coincidence in Canada after a disillusioned Minx quit his job at Cool IT. Minx had been assigned a multiphase cooling project that was pulled because the company didn’t want to take on the risk of developing a new technology. The two old friends decided to start a company outside of Vancouver, where Minx could bring his multiphase cooling ideas to commercialization. It was there that CapTherm was launched in February 2011 and soon after raised a $600,000 early investment from Greenscape Capital.

With Minx’s experience and reputation in IT cooling, it seemed practical to enter that market, and CapTherm has been iterating prototypes for a year and a half ahead of its commercialization early next year.

“We see the IT market as a low-hanging fruit,” Minx said. “We have all the contacts necessary in the IT world to launch a retail product. In essence, the IT opportunity creates brand awareness, technology awareness, educates consumers about our technology, and is a nice opportunity for us to ramp production, validate the manufacturing process, and prove that we’re able to manufacture these units and this technology at a competitive price with great quality. However, the medium- and long-term approach at CapTherm is definitely to take these technologies and apply them to a multitude of other markets, including advanced materials like graphene with the help of our development partners Focus Graphite and Grafoid, wind and solar power applications, high-quality electronics, generators, electric vehicles and EV charging stations.”

Minx pointed out that CapTherm already has some prototypes for battery-cooling products that could lead them into the EV and EV charging station fields. But the start-up needs to focus its resources on the IT market for now and branch out once it’s at or near the break-even point. It also helps that in the IT world, where there is little protection if current liquid cooling systems leak, the CapTherm product offers “a huge value add over the current technology,” according to Minx.

There will also likely be an early-adopter period for CapTherm’s systems, which will cost a premium until economies of scale help them compare in price to current liquid cooling systems. “Primarily we’re more expensive on the material side, because we use all metal-to-metal connections,” Minx said. “At the same time, we save on components. We don’t utilize a pump.”

Assuming the CapTherm multiphase cooling system eventually becomes more of a volume product, the company will look at opening it up to all sorts of industries, but there is still at least one limitation to it.

“The version we’re releasing is gravitationally-dependent, meaning if you were to flip your car upside down, it would no longer work,” Minx said. “Initially, we were going to commercialize an even more sophisticated multiphase technology, but with the technology that we’re now launching in Q1 next year, there is still gravitational dependence. So the technology is now more affordable, but if there is any drawback so to speak, this would be the one. It’s interesting – with the less sophisticated technology, you can cover about 90 percent of all market opportunities, because they don’t look for orientational independence.”

Minx figures the only applications gravitational dependence excludes them from are aerospace, some military applications, zero-gravity environments, and smartphones. Yet that leaves them with plenty of possibilities for servers, work-stations/desktops, EVs, LED lights, high-beam lighting and floodlighting, and telecommunications.

“We’re shying away from completely commodity processes and products for the time being,” Minx said, “because it’s very difficult for a start-up company to compete against China. So we’re not interested in cooling LED light bulbs that you can buy for $5 at Home Depot, but there are floodlighting applications where the cooling system for the LED alone costs $10,000 or even $30,000 as a matter of fact. It’s those specialty applications we’re interested in working on for the next few years.”

Multiphase EV plan

CapTherm cites battery cooling as an area that has been woefully underaddressed in the EV industry, and points to problems that can arise when there is poor thermal management of batteries: safety hazards from uncontrolled battery temperatures, batteries wearing out faster, reduced performance from unbalanced modules, and impacted charge acceptance. Once its multiphase cooling system hits EV manufacturing, CapTherm believes it will offer such benefits as virtually maintenance-free operation, which reduces costs; better temperature control with minimal variations, which can lead to better battery capacity; improved charging times, range, reliability, life cycles, and life expectancy; and a lighter, more compact cooling apparatus.

“There really is no drawback to the customer experience,” Minx said. “Whoever adopts our technology is going to have a considerable competitive advantage simply by using what our technology is going to enable the battery to do.”

Batteries aren’t the only area in which CapTherm could impact the EV industry. Its multiphase cooling also can apply to insulated gate bipolar transistors (IGBTs), the high-power switching transistors that switch large amounts of power from the battery pack to the motor to accelerate quickly.

The growing number of EV charging stations could also get a boost from CapTherm’s technology. “Energy conversion efficiency is higher if you utilize a better cooling technology,” Minx said, “so it doesn’t just apply to the EV market – it also applies to the charging stations. If you reduce temperature, you increase energy efficiency. If you spin the fan at a slower speed, it consumes less power, and the underlying equipment becomes more reliable.”

CapTherm’s system could integrate with EVs in a variety of ways, such as drop-in replacements for existing batteries or an add-on battery that would work with the existing infrastructure. There are also prototypes of systems that would actually fit inside the cells of a battery pack such as the Chevy Volt’s. “I can’t really speak too much about it, but that is a unique project we’re working on,” Minx said. “We’d love to find somebody to partner up with us on that as well.”

When cooling heats up

There are at least a couple of other companies with related technology, that also claim to offer the first multiphase cooling system. These include Thermal Form & Function in Massachusetts, and the larger Communications & Power Industries (CPI), headquartered in Palo Alto, California. The competition should make watching this new sector more interesting, and hopefully help bring the advantages of multiphase cooling to the EV world even sooner. For CapTherm, developing strategic partnerships could help establish it as the front-runner in multiphase cooling. The company struck its first joint venture with Focus Graphite in April. The agreement will see Focus Graphite’s Grafoid subsidiary supply CapTherm with high-energy graphene materials and its science for incorporating that graphene into CapTherm’s multiphase cooling systems for EV batteries and LEDs.

Graphene is a superconductor with great lateral and vertical heat-spreading properties. “Graphene simply possesses excellent thermal properties,” Minx said. “Our multiphase technology could employ graphene and make it perform even better. We’re really happy about the partnership.” If it goes as planned, the Focus Graphite joint venture will only be the first of many partnerships CapTherm enters for EVs and other markets, and the company’s initial foray into IT multiphase cooling systems next year will serve as a jumping-off point for what’s to come.

“The IT launch is kind of a marketing exercise,” Minx said. “We want to create brand awareness. We want people to recognize what CapTherm is and have a showcase project where we can say we have 10,000-20,000 units in the field; we manufacture them in North America at high quality for a good price; and we believe that will build trust with the larger companies to embark on R&D project with us. We’re very open to that. If the right opportunity were to walk across our table today, we would certainly allocate resources to it.”

This article originally appeared in Charged Issue 9 – AUG 2013