Spider9 weaves a matrix for stationary energy storage and shows that when it comes to fitting battery technology into electric vehicles, it’s not all for one and one for all.

Many real-world technologists and engineers take inspiration from the worlds of science fiction, where recurring themes of systems theory take shape in the Grid of Tron or the matrix of, you guessed it, The Matrix. Yet such fantasy worlds of total interconnectedness are based in turn on the reality of interconnected systems. In the case of vehicle electrification, the research of academia connects to profit-driven businesses. Each of those businesses makes up a small part of the overall EV industry, which in turn benefits from the larger continuing process of making renewable energy plentiful and cost-effective.

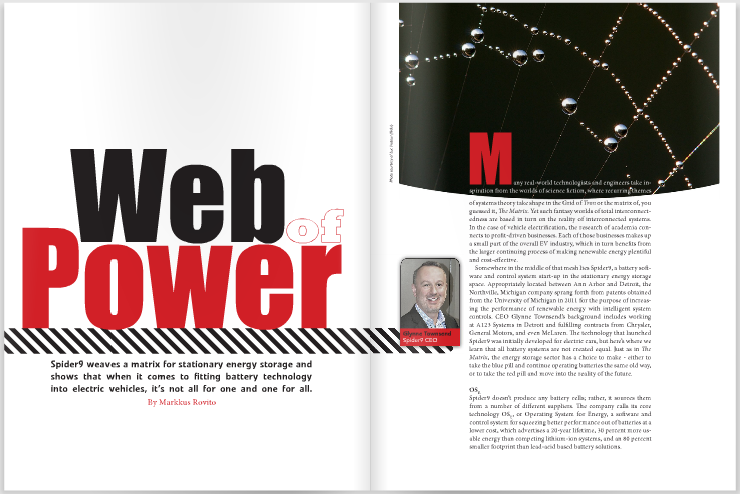

Somewhere in the middle of that mesh lies Spider9, a battery software and control system start-up in the stationary energy storage space. Appropriately located between Ann Arbor and Detroit, the Northville, Michigan company sprang forth from patents obtained from the University of Michigan in 2011 for the purpose of increasing the performance of renewable energy with intelligent system controls. CEO Glynne Townsend’s background includes working at A123 Systems in Detroit and fulfilling contracts from Chrysler, General Motors, and even McLaren. The technology that launched Spider9 was initially developed for electric cars, but here’s where we learn that all battery systems are not created equal. Just as in The Matrix, the energy storage sector has a choice to make – either to take the blue pill and continue operating batteries the same old way, or to take the red pill and move into the reality of the future.

Somewhere in the middle of that mesh lies Spider9, a battery software and control system start-up in the stationary energy storage space. Appropriately located between Ann Arbor and Detroit, the Northville, Michigan company sprang forth from patents obtained from the University of Michigan in 2011 for the purpose of increasing the performance of renewable energy with intelligent system controls. CEO Glynne Townsend’s background includes working at A123 Systems in Detroit and fulfilling contracts from Chrysler, General Motors, and even McLaren. The technology that launched Spider9 was initially developed for electric cars, but here’s where we learn that all battery systems are not created equal. Just as in The Matrix, the energy storage sector has a choice to make – either to take the blue pill and continue operating batteries the same old way, or to take the red pill and move into the reality of the future.

OSE

Spider9 doesn’t produce any battery cells; rather, it sources them from a number of different suppliers. The company calls its core technology OSE, or Operating System for Energy, a software and control system for squeezing better performance out of batteries at a lower cost, which advertises a 20-year lifetime, 30 percent more usable energy than competing lithium-ion systems, and an 80 percent smaller footprint than lead-acid based battery solutions.

After whiteboarding OSE’s advantages for its customers, the founders noticed that their company sat in the middle of nine extending characteristics – like a spider in a web – and christened the company Spider9. If it fulfills its goals, OSE should alleviate or solve the problems of other energy storage systems, namely, huge operational and maintenance expenses, not meeting performance and life expectations, and obsolescence when new cell technologies appear.

OSE’s nine core characteristics are:

- Reconfiguring electrical architecture in real time to adapt to customer demands, environmental conditions, and system status, thereby delivering more energy with less maintenance and increasing the life of the system.

- Integrating all energy generation and storage components and all battery chemistries into a single user interface.

- Predicting where the lowest-cost electricity source is according to analytics that consider utility rates, scheduled load requirements, past load requirements, and forecasted solar and wind availability.

- Balancing each cell during every charge cycle to reduce system stress and allow more energy extraction from every cell.

- Saving customers money through lower up-front costs, improved performance, lower operating costs, and longer life.

- Storing energy from renewable sources so it can be used at any time. The system provides ramp rate control, voltage and frequency regulation, off-grid operation, and other management functions.

- Alerting operators with automatic notifications if a component fails or conditions exceed normal ranges. Alerts detail the nature of the problem, its location within the system, and whether the operator should act immediately or save money by waiting until the next scheduled site visit.

- Isolating compromised components, allowing up to 95 percent of the system to operate normally, while preventing a fault from propagating and damaging additional components.

- Reporting to customers how much money they have saved, how each component performs, and whether any service is needed from data stored on the Spider9 Cloud.

Worldwide storage

In June, Spider9 started taking orders for its residential and light commercial system, the Energy Vault, which basically scales down Spider9’s commercial and utility product, the modular 500 kWh Mega Vault energy storage unit.

Townsend eyes potential customers in growing markets spread over the globe, but immediate demands need filling in the western US and especially Germany. “It’s the leader in Europe for renewable energy,” Townsend said. “Most of its renewable energy is from residential solar. They’ve now initiated a program that funds 30 percent of the cost of energy storage for a home.”

Much like EV manufacturers taking advantage of government programs to assist the adoption of electric cars and trucks, Spider9 wants to establish itself commercially at first where government requirements and assistance can lend a hand. In Europe, the EEC wants to generate a minimum of 13 percent of its grid energy from renewables, and both Italy and the UK are evaluating residential programs similar to Germany’s for subsidizing energy storage. “Without any storage, renewable energy just comes onto the grid when it’s generated, and there may not be any use for it,” Townsend said. “That can cause a lot of instability, like blackouts and failures of the grid, which is totally unacceptable.”

Townsend sees every inhabited continent as a growth market for Spider9. “Japan’s energy sector investments are fueled by a lot of concern over the nuclear failure about two years ago, and they’ve become a very large market for energy storage,” he said. “China, with its incredible renewable footprint has the least amount of storage. You look at some of the areas where there’s poor power quality for consumers, like India, with the massive blackout they had last year and the chronic power supply issues they continue to face. In Africa and South America there is not enough reliable, well-supplied, high-quality electricity in a lot of the places where it needs to be. Australia’s been another very interesting market for the product. There used to be a high feed-in tariff for residential solar electricity supplied to the grid, up to 40 cents/kWh in some cases, but due to recent policy changes the feed-in tariffs have been reduced and charges increased for time of use and service connection. This forces consumers to store and use their energy rather than sell it on the grid. In these circumstances, taking a home effectively off-grid with a solar installation and storage asset becomes economically viable, and in fact provides a payback period of less than five years.”

Essentially, Spider9 sees the entire power-hungry world as its oyster, and it wants a piece of the $20 billion that some forecasters predict for the renewable energy market by 2020. “It’s a very exciting market to be in,” Townsend said, “and really it’s about going where the markets are, which is where people pay a high cost for electricity or there’s not enough supply or reliability.”

Chemistry-agnostic

As it tries to expand its web of energy storage around the world, an advantage for Spider9’s OSE Vault systems could be that they can work with any battery chemistry. They’re also flexible enough to install as new systems or retrofit into existing systems. Currently, Spider9 focuses mainly on Li-ion, but Townsend hesitates to say whether he thinks Li-ion will be the clear winner for energy storage. He estimates that there’s only about 150-200 MW of Li-ion energy storage units out there right now, many of them demonstration projects.

Although Li-ion occupies an 80 percent smaller footprint than lead-acid batteries, Townsend thinks lead-acid is still developing and improving. “If you look at sodium batteries, I really think lithium’s got the better of them in terms of power applications,” Townsend said, “but some of the zinc-air batteries look promising in terms of power densities. The suitability of a given chemistry will depend on its life, its physical footprint, the budget that’s available, and the system’s power and energy requirements. That’s why we focused on developing an operating system and architecture that’s not predisposed to a certain type of chemistry. We can manage, reconfigure, extend the life and improve the reliability of any battery cells, essentially future-proofing the system from changing technology and revenue streams. Our early deployments have been with lithium, because that’s really what the market and applications have called for to date.”

Reconfigurability

The University of Michigan’s balance control technology, which spawned Spider9, was an infinitely reconfigurable series-parallel matrix structure. To commercialize the product, Spider9 added some system resolution to it, but the reconfiguration capabilities of the company’s Vaults still count as one of the strongest selling points; they make it possible to achieve more energy and longer life from the same batteries.

As a comparative example, Townsend proposed a battery unit with blocks of energy that are placed in series strings and then parallel, becoming a fixed architecture. “If you have one cell that fails,” Townsend said, “it could compromise the whole battery. Then you’ve got the issue of determining which cell failed, breaking and replacing welded joints to physically remove it, replacing more cells than you need to due to accessibility issues, and keeping the system offline for an extended period of time to rebalance the pack, because you’ve now put a different block of energy into it. That’s a real litany of the real-world practical problems.”

However, Spider9’s Vaults can isolate a cell failure, and reconfigure the system so that it isn’t forced offline, getting more energy out of the pack.

Reconfiguring also comes in handy for maintaining energy levels while discharging a battery. “When you’re discharging from top of charge to bottom of charge, the voltage can decrease by 30 to 60 percent. As this energy is fed into an inverter, there’s a lot of heat generated at the bottom of charge where you have low voltages and high currents. We’re able to reconfigure these series-parallel elements to effectively boost the voltage level of the system and maintain a higher system voltage. We avoid inverter cutoffs; we create less heat; we extend life on an architectural basis. Our research shows we get up to 15 percent more energy out of the battery by doing that than comparable systems.”

Reconfiguring also comes in handy for maintaining energy levels while discharging a battery. “When you’re discharging from top of charge to bottom of charge, the voltage can decrease by 30 to 60 percent. As this energy is fed into an inverter, there’s a lot of heat generated at the bottom of charge where you have low voltages and high currents. We’re able to reconfigure these series-parallel elements to effectively boost the voltage level of the system and maintain a higher system voltage. We avoid inverter cutoffs; we create less heat; we extend life on an architectural basis. Our research shows we get up to 15 percent more energy out of the battery by doing that than comparable systems.”

It’s that usable energy that Spider9 emphasizes as an advantage to its OSE products, as chief operating officer Dave Park has said. “Our competitors tend to quote the maximum storage capacity, but are never clear on how much of their energy capacity is actually usable. Usable energy is what matters.”

No vehicles for Spiders

While reconfigurability may give Spider9 a leg up in stationary energy storage, the same system doesn’t translate well to EVs. Although this technology originated as an automotive solution, it would have passed on a significant cost to the OEMs, which Townsend said would be rejected in the EV market. It turns out that this system currently makes the most sense for what, compared to EV batteries, are much larger-format arrays.

“In a vehicle battery, you really only get two parallel strings, which isn’t a lot to reconfigure,” Townsend said. “The automobile manufacturers put all their validation into making sure this 2P configuration is reliable and lasts as long as it possibly can, and really they only monitor those cells without actively managing them. We look at it differently. We’re trying to pull energy out of that battery. That’s the primary function, whereas in a vehicle, you’re trying to get a driver from point A to point B as economically as you can.”

Spider9 has looked at some EV applications in the high-performance arena, where electric motors drive at higher RPMs, and therefore keep a higher torque curve coming out of a power train. “We just haven’t had the bandwidth yet to try to commercialize on that,” Townsend said.

There are many applications that a stationary energy storage system can support, from load shifting, which requires a slow transfer of energy, to frequency regulation, renewables firming or PHEV charging stations that need a fast transfer of power. Very similar to the differences between battery packs for EVs and HEVs, each application has differing needs and complementary battery chemistries to support them. Townsend believes that too many EV battery companies have tried to overlap into the stationary storage market when their products aren’t exactly suited for them. Because these companies don’t have enough orders yet from EV makers, they’re trying to capitalize on their products in the wrong way.

“What you find is that a lot of the square pegs don’t fit into round holes,” he said. “They’re using a prismatic cell in a stationary application, and it’s not ideal. A prismatic cell was designed specifically to go down the center of a vehicle and maximize the volumetric density of the energy sent down that tunnel. If you put that into a stationary application, it creates all sorts of cooling and serviceability issues. The driving factor is not volume package density like it is in a vehicle. It also leads to a lot of system cost issues. Imagine that these things are tasked with multiple applications. If you have a cell that fails, and you don’t have the robustness that the OSE provides, you’ve lost a system.

Then you’ve got to go out and fix it. It’s a very costly problem that a lot of people in the stationary storage market aren’t considering. The up-front cost of purchasing an energy storage system is only one third of the total cost of owning and operating it over a twenty-year life. Most people miss this point. By having an intelligent battery with a flexible chemistry platform, you can ensure your investment is safe from changing revenue streams and evolving chemistries, reducing your up-front cost and slashing your operating costs, saving up to 40% compared to traditional systems. It is those issues that we are addressing in a very significant way.”

This article originally appeared in Charged Issue 10 – OCT 2013