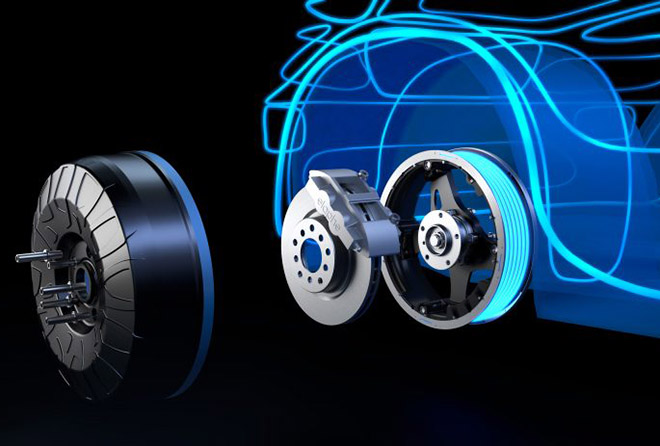

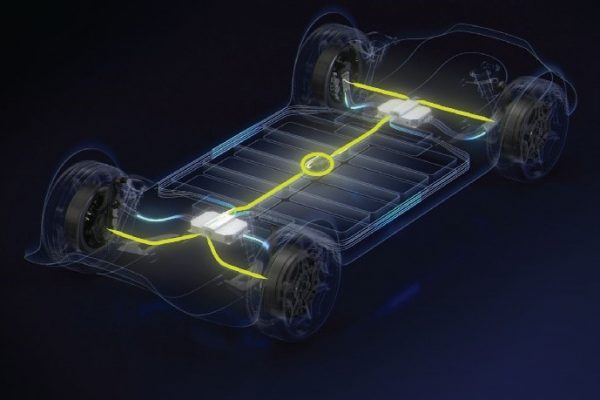

Are in-wheel motors the future? We’ll see—no OEM that we know of is using them in any large volumes yet, but companies are definitely still pursuing the technology. In-wheel proponents point to significant space and weight savings, which can deliver reduced energy consumption.

Motor-maker Elaphe and component supplier McLaren Applied have partnered to develop an in-wheel propulsion system for “a vehicle segment of highly efficient and hyper-responsive electric vehicles.”

The system pairs McLaren’s inverter technology with Elaphe’s direct-drive in-wheel motors and vehicle controls. The companies say it offers “best-in-class long-range cruising efficiency and unmatched vehicle controllability, with a torque response five times faster compared to existing systems.”

Elaphe says its in-wheel technology has demonstrated energy efficiency of over 97% on vehicles such as the Lightyear Zero and Aptera’s EV. With torque densities up to 460 Nm/liter and 100 Nm/kg, Elaphe’s in-wheel technology “takes advantage of the high control bandwidth of each wheel to enable premium safety capability.”

McLaren Applied specializes in high-performance power electronics, and has supplied inverters for both Formula 1 and Formula E since 2013. McLaren’s 800 V silicon carbide inverter, IPG5, offers “unrivalled gravimetric and volumetric power density of 90 kVA/kg and 130 kVA/L respectively, variable switching frequency, and efficiency of up to 99%.”

Source: Elaphe