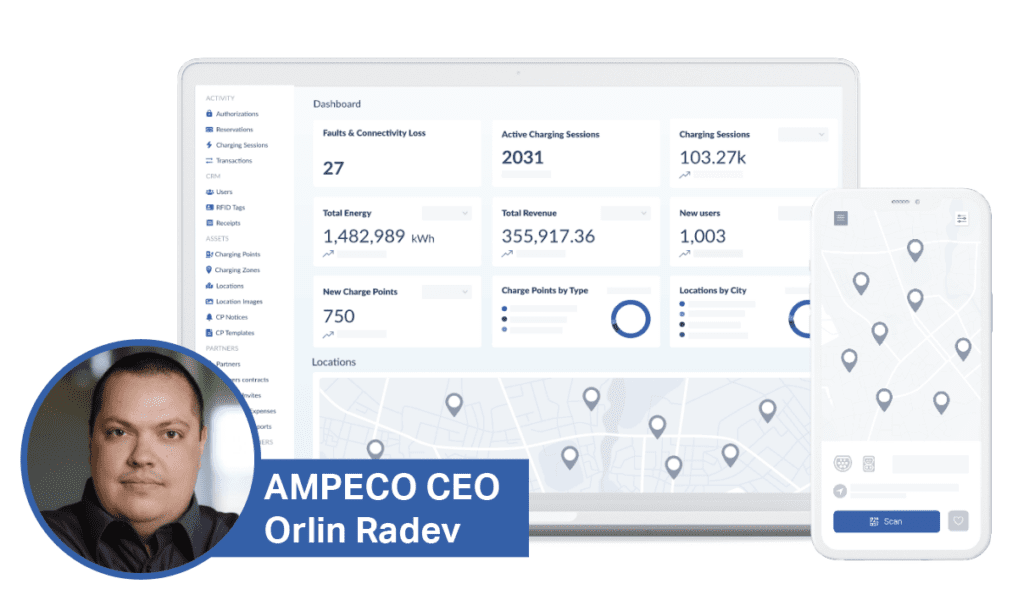

AMPLY Power says its charging as a service model provides 99.9% uptime, critical to scaling EV deployments

Fleet charging management may not be the most glamorous segment of the EV industry, but it is emerging as an extremely important component of the future EV ecosystem. As commercial fleets electrify, they are finding that they need expert help to design, install and operate their charging infrastructure. During previous tech revolutions, third-party contractors emerged to provide turnkey services to companies for things like data centers and solar installations. Now innovative companies are meeting the demand for similar services in the fleet charging realm. Charging as a service is the hottest trend in the EVSE world—it offers savings to fleet operators today, and once the nascent technology of V2G takes off, it could offer truly game-changing capabilities for utilities.

Three-year-old AMPLY Power is already providing charging management services to several fleet customers, and the company recently won a high-profile contract to provide managed charging for New York City’s largest pilot of e-school buses, to be operated by Logan Bus, the city’s largest school bus provider.

Charged had a chat with AMPLY CEO Vic Shao.

Charged: Could you explain a bit about why the charging as a service model is needed?

Vic Shao: For new EV fleet operators, charging as a service can be a difficult concept to wrap their heads around without some sort of comparison to parallel industries, so when I talk about charging as a service, I typically draw an analogy to solar PPAs [power purchase agreements].

You don’t really find customers anymore that would select solar panels and inverters on their own, hire a construction crew to build a system, then work with the utility directly on the utility interconnect. You would have a solar developer figure out all that for you and install it, and for large enough deployments, you would do a 20-year solar PPA.

I also tell the story of data centers. Twenty years ago, large companies would put a whole bunch of server blades into electrical closets, thinking this can’t be that hard—just servers in a closet and away we go. Well, as it turns out, it is a lot more complex than one would imagine—operating system upgrades and antivirus protection and batteries to back up the servers and cooling systems for that closet…all of this mess. So, what ultimately happened, of course, is that everybody started using Amazon Web Services or Microsoft Azure, and just buying the output and leaving all of the complexity to a data center operator.

Our mission is to provide uptime reliability, mission-critical robustness for charging of electric fleets—buses, trucks, light-duty vehicles, school buses and the like. We have live customers across all of those segments.

I’ve been a long-time clean energy entrepreneur. Prior to AMPLY, I founded and ran a company called Green Charge Networks, which over the span of eight or nine years became the largest distributed energy storage provider in the country. Back in 2016, the company was acquired by a French entity called Engie, which is the largest independent power producer in the world. I went on to head up Engie’s global energy storage practice for a couple of years prior to starting AMPLY.

So, the business thesis behind AMPLY is that I simply took what worked for me on my last company with energy storage—and I would argue it’s true for solar, data centers and cloud computing as well—and applied the as-a-service model to charging for fleets. And I believe that this is what’s needed in this market for the industry to scale.

Three big challenges for large EV fleets

Charged: What are some of the challenges that a typical fleet manager has to go through as they electrify?

Vic Shao: By now we’ve touched hundreds of fleets all across the country, and it seems to always boil down to three major fundamental issues.

In California, electricity costs for charging fleets could be up or down 400% in a single day.

The first is the cost of electricity. Fleet operators are used to a scenario with diesel or gasoline, that pricing goes up or down by, let’s say, 20% in a given year. With electricity, it’s fundamentally a much more volatile fuel pricing structure. In California, electricity costs for charging fleets could be up or down 400% in a single day. And there are something like 2,000 electric utilities across the country, all with their own individual tariff structures, time-of-use schedules, demand charge rates and whatnot. So, it’s highly complex—it’s like going to a gas station and it could be $3 a gallon, or it could be $12 a gallon, and it just depends on all of these extenuating circumstances.

Now, if you are a fleet operator, and fueling cost is your second-highest operating expense, right behind drivers, well then, if you don’t know what your costs are going to be next week, next month, next year, you’re going to have a really hard time committing to a large production-scale rollout. You’re kind of stuck in pilot mode, and that’s what we see all the time. A lot of fleets that have tried electric, they don’t have a path to scale because of this fueling price issue.

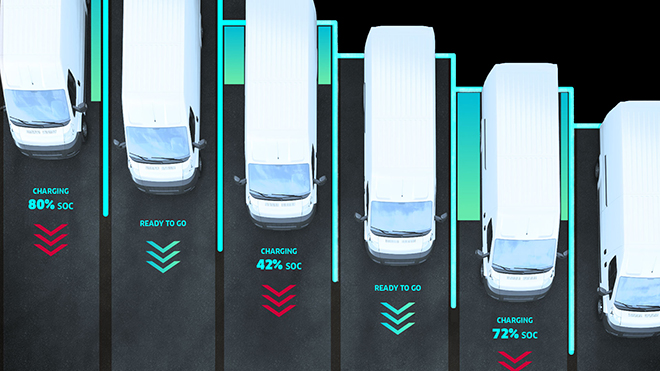

The second big issue is that, across these hundreds of fleets that we have touched, we have yet to come across a single fleet that standardizes on one OEM’s products—one make and model of electric vehicle, one charging hardware OEM. Without exception, every single one of them operates a mixed fleet, with mixed vehicle and charging hardware sets. They need to have an operating system that ties all these hardware sets together, that will deliver reliability, charge readiness at the time that they need the vehicles to roll off the lot.

Without exception, every single one of them operates a mixed fleet, with mixed vehicle and charging hardware sets. They need to have an operating system that ties all these hardware sets together.

And then the last issue—a big issue—is that it’s not a five-minute fuel-up anymore. No matter how you slice it, it’s going to be several hours of dwell time, so that means, for mission-critical operations, you really need to schedule the charging into the daily workflows of these vehicles. That means dispatch system integration, telematics integration, back-office ERP [enterprise resource planning] integration.

All three of these problems that I narrated are software-related. It’s not hardware, it’s software-related challenges, so what is required for the industry is an operating system that addresses all these points, and that’s essentially what AMPLY has been working on ever since our founding. We call it a charge management system, and it’s an operating system that tackles all three of these issues head-on. And the end output is that for all of our fleets, the charging infrastructure is 99.9% uptime available, robust with failovers and redundancy, and delivering energy savings versus an unmanaged scenario.

Charged: What kind of problems do they see because the vehicles and the charging systems are not standardized to one manufacturer?

Vic Shao: What we run across all the time is, a charger company with a network-enabled smart charger, during the demo phase with the customer, will say, “Look, you can log into the web portal, you can see that particular charger and what it’s doing in real time, and if you stick the charger into the vehicle, hey, look at that power spike.” The problem is that it’s completely beside the point. This is like if you’re operating a data center or something, and you’re logging into a particular server blade to see how it’s performing—it’s irrelevant. No fleet operator with 50 or 100 vehicles in their parking lot is actually going to do that on an individual basis.

What you need is a system that operates all of the charging and gets a system-level read on what’s going on. One of the problems with the individualized charger approach is that the charger is giving a particular reading on the state of charge, whereas, in their dispatch system, the expected state of charge is different, or the telematics system is giving them a different reading on various data points. Which one is the truth? Which one is the valid data point? You can’t dispatch a bus to drive out for the day’s 100-mile routes when you only have 20% state of charge left, so you need to have accuracy.

When you get a product spec on a DC fast charger, oftentimes what’s missing is the audible noise level of that charger. How many decibels at three meters?

Another one is a hardware-level example—we encounter this all the time. When you get a product spec on a DC fast charger, oftentimes what’s missing is the audible noise level of that charger. How many decibels at three meters? Now, when you’re installing a couple of chargers in one location, it may not matter all that much. But the kind of projects that AMPLY gets into—we announced a 20-year charging agreement with Anaheim transit last year, with 46 buses and 46 chargers—well, when you have that density, you better believe audible noise is a big deal. So, we would go back and ask the sales rep on that charger, “Hey, your data sheet is missing the audible noise. What is it? Can you tell us?” And the answer is often, I have no idea. In fact, nobody’s even asked that question before.

Infrastructure planning from day one

Charged: Let’s say, for example, a school district wants to deploy some electric school buses. Can you walk me through how your team gets involved with the project and give me the step-by-step?

Vic Shao: We engage in all different sales cycles. In the best-case scenario, we get involved upfront, before they even come out with a specification or an RFP, and in those circumstances, we can help them design, help them through the layouts. What is most efficient? What are your routes? How many miles a day? How many days of the week? We get our hands into the design of what they’re trying to accomplish, and that’s the most ideal case. We help them with the design, we help them with mapping out the interfaces with the utilities. Do they have existing capacity, or do they need to go back to the utility for a service upgrade? We walk them through all of that, and then we bid the job. If we win it, then we go through with the implementation and the operations.

However, we get into a lot of situations where the operator already has vehicles on order, they’re arriving in three months, and they haven’t even started on the infrastructure. Infrastructure is still often an afterthought in the marketplace.

In those kinds of situations, we have to do what we have to do to get the customer up and running. It may be too late for us to specify the chargers, and we have to live with whatever is already on order. But we’ve touched enough hardware sets by now that, for the most part, we can operate using our software. We can manage and operate 90% of what’s out there today already—ChargePoint, BTCPower, and so forth. Most of the time, it’s not a huge surprise to us.

However, when we get into a situation where we’re just implementing our software on top of whatever already exists, we can’t fully wrap the project. In other words, we can’t give our customers a performance guarantee on the operations. The ideal outcome is for us to fully wrap a project, so we can give our customers a performance guarantee of a 99.9% uptime. And we can give them a savings guarantee with managed charging. But if we get engaged late, then a lot of times we can’t guarantee the results.

Charged: You announced a project with Palermo, California school buses that will provide a $1.19 per gallon equivalent. Can you explain how you would help someone optimize for fuel costs? What can you do to drive those costs down over time?

Vic Shao: We tell the school district, whenever your drivers get back, just plug in the buses. They’re not going to energize right away, but when they’re needed the next morning, when you need to drive the routes, then these buses are going to be charged up, ready to go. So, from the time that they plug in the buses—let’s say 4 or 5 pm—until the next morning when they need to operate, we do a few things. We sequentially charge them as needed, or during the time when energy cost is lowest, when the demand spike in the building is reduced. Whenever there’s a dip in the power requirements of the building, we use that to charge up the buses opportunistically, while still meeting obligations that our vehicles will be charged the next day.

Whenever there’s a dip in the power requirements of the building, we use that to charge up the buses opportunistically while still meeting obligations that our vehicles will be charged the next day.

Second thing that we do is, we enroll the customer in grid services and demand-response applications. School buses are actually a perfect case for this. They are usually back and plugged in by the time that the grid really needs that capacity—the 4-to-9-pm window in California in the summertime is when energy is the most expensive. The grid is spiking during that period of time, and it just so happens that all the buses are plugged in and available, so the time-of-day use case is very strongly aligned with school buses.

V2B now, V2G in the future

Charged: Do you have active fleets that are doing that kind of demand response, or is this something that will be rolling out in the future?

Vic Shao: We’re doing that now. In fact, we had a ribbon-cutting ceremony last week in New York City with a school bus operator called Logan Bus, which is the largest school bus operator in New York City. I think they have something like 2,500 school buses out of 12,000 in New York City. We deployed a very small portion of their fleet just as a start, and on that project, we’re tied in with a demand response [DR] aggregator called CPower, which is going to be dispatching DR for us on that project. So it’s already in place.

Charged: So, in those cases, a utility will call the buses to supply power. And in order to get optimal rates from the utility, do you have to guarantee any kind of capacity at certain times?

Vic Shao: Correct. We have to guarantee a capacity at a certain time of the day. The utilities in Con Edison’s territory, in New York City, they typically have 20 or so demand response events, maybe 30 DR events a year in the summer months. So, you enroll in these programs, you get a day-ahead notice for the event, and you have to allocate certain hours, 3 or 4 hours at a time, when these assets are going to be available and can be used for demand response purposes. Demand response is not pumping power back onto the grid—it’s just that the building load is reduced. We can dispatch power from the bus battery to serve the building, to reduce the overall net draw from the grid, but it’s not pumping power back onto the grid.

We can dispatch power from the bus battery to serve the building, to reduce the overall net draw from the grid, but it’s not pumping power back onto the grid.

Charged: Are there any projects that are looking to pump power to the grid, or is that still in the distant future?

Vic Shao: It’s not in a distant future—in fact, the DR is just the first phase of the Logan Bus project. The hardware set that is in use at Logan Bus is V2G-capable. Right now we’re not doing V2G, but it’s a demonstration that we can do in the coming months. And I use the word demonstration very carefully here, because it requires participation, not just from AMPLY or Logan Bus, but Con Edison has to be on board for that demonstration in order to make this work.

The utility has to be involved, because when you pump power back onto the grid, it needs to be very carefully thought through. In solar it’s called net metering, when you deliver power back onto the grid. In fleet charging, the term is V2G. And when you spin the meter backwards, when you push power back onto the grid, in Con Edison’s territory, there are network protectors in the distribution lines. When you see a reverse power flow, those network protectors will trip so that it’s not endangering the equipment.

It requires participation from Con Edison for the demonstration, so that we’re not endangering the utility assets, so V2G is very much in a demonstration phase right now. There are no production V2G programs out there in existence, but the equipment that we have deployed is capable.

Charged: Do you ever deploy stationary storage in these systems?

Vic Shao: Stationary storage is the world that I came from—prior to AMPLY, I founded and ran a stationary energy storage company, so it’s a topic that I know really well. For AMPLY, stationary storage is an option for our customers, for resiliency and backup purposes. For mission-critical operations the question is, if the grid goes out, are we screwed? Can we still get service? And the answer is yes, we can install a stationary storage system for you, to tide you over, but it’s not going to be a full fleet—it’s going to be a select handful of vehicles that you can still continue to operate on an emergency basis. And in those cases, we typically would also pair stationary storage with a solar installation, so that the stationary battery can refill itself when the sun is shining. Again, it’s all for the purpose of resiliency.

99.9% uptime

Charged: After you help a school district electrify, what do you do in the next 10 years for that operation?

Vic Shao: We provide the customer with 24/7 support. We are monitoring all of the chargers in real time. We’re seeing their performance. We’re seeing exceptions. For example, for plug-in chargers, we are seeing across the board with our customers that 5% of the time, the guy sticking the plug into the vehicle doesn’t fully insert the plug all the way, so the vehicle cannot energize. In those circumstances we send automatic text alerts, we notify the folks on site: Please go back to bus number one and reinsert. Because what happens without that monitoring is that the morning-shift driver comes in and notices that the bus is not charged, and they’re scrambling to find a replacement vehicle. That bad charging scenario doesn’t need to happen too many times for the fleet operators to go, well, this technology is just too new, it’s not reliable, and I better go back to fossil fuels.

That bad charging scenario doesn’t need to happen too many times for the fleet operators to go, well, this technology is just too new, it’s not reliable, and I better go back to fossil fuels.

That’s the last thing that we want the customer to experience, so proactive alerting, monitoring, energy management is huge. We monitor the load at the meter—exactly what the utility meter sees, we see in real time. The customer doesn’t experience demand charges, we manage the charging so that the profile at the building is as flat as possible, so we get the lowest cost of energy. When there is a hardware problem, we know about it before the customer does, and we try to remotely troubleshoot, diagnose, triage the situation. As a last resort, if we can’t bring it back up remotely, we will roll a service technician to the site, get that charger fixed or replaced if necessary.

Uptime is something that we take very seriously. We have been benchmarking our uptime availability ever since the very first customer went live a year and a half ago. So today we’re very proud of the fact that we’re at 99.9% uptime on all of the chargers that we manage across our customer base.

This article appeared in Charged Issue 55 – May/June 2021 – Subscribe now.