Researchers around the world are working on improving various aspects of battery performance – capacity, charging speed, usable life. Scientists at the Karlsruhe Institute of Technology (KIT) are focusing on the speed with which they can be manufactured, which has a direct effect on costs.

The researchers have increased the manufacturing speed of electrode foils coated batch-wise by a factor of three, using a flexible slot die process that enables production of any pattern with high precision at high speeds.

After three years of research, a team headed by Professor Wilhelm Schabel and Dr Philip Scharfer has succeeded in increasing the speed of intermittent production of electrode foils to 100 meters per minute. So far, 25 to 35 meters per minute has been the industrial state of the art.

SEE ALSO: New study: Rapid charging doesn’t damage lithium-ion batteries as much as thought

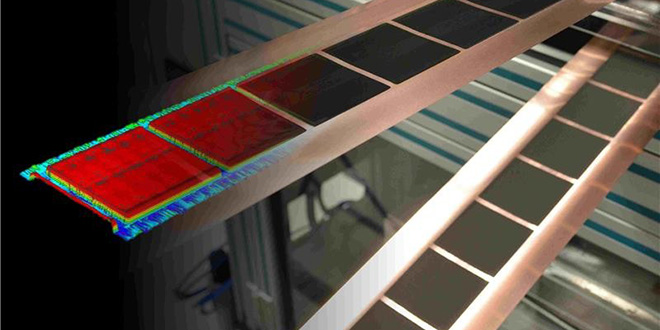

When producing an electrode foil, a slurry containing the active material, carbon black, binder, solvent, and additives is applied onto a substrate foil made of copper (for the anode) or aluminum (for the cathode). The coating is often processed continuously, but intermittent coatings are associated with a superior processability for subsequent process steps.

“In the case of intermittent coating, defined start and stop edges are required no matter the coating speed,” Schabel explains. “In our process this is achieved by a membrane that quickly moves back and forth in a controlled manner in the coating head, i.e. in the slot die.” No other movable parts are required. This allows high frequencies of up to 1,000 electrode patterns per minute, and highly precise coating.

Using a similar process, the KIT scientists have already successfully produced electrodes for EVs at pilot scale. “The new coating technology, in combination with the helix technology developed and patented by KIT for the production of spirally wound lithium-ion batteries, offers the potential of reaching cost leadership,” said project leader Dr Andreas Gutsch.

Source: Karlsruhe Institute of Technology via Science Daily