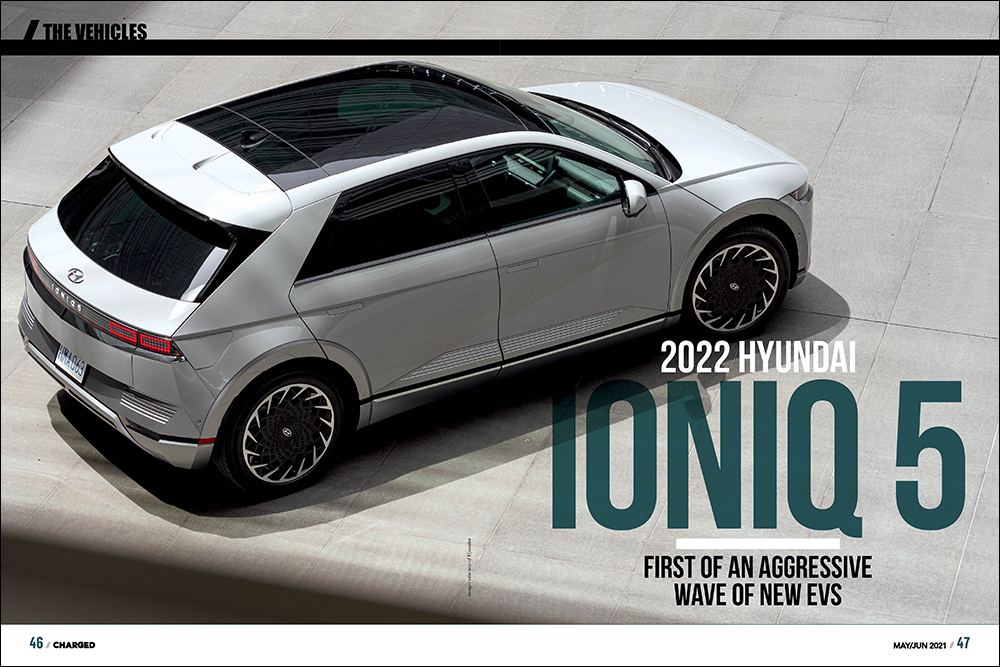

If there’s one thing everyone can agree on about EVs, it’s that ranges need to become longer. That means battery capacities need to grow, and therefore charging levels will have to increase as well, if charging times are to stay the same (or, preferably, become shorter).

One company that’s been working on higher charging levels is Porsche, which has set its sights on 800-volt DC charging technology. The VW Group subsidiary developed an 800-volt charging system (double the voltage of the current CCS standard) for its Mission E concept, which was shown in Frankfurt last September.

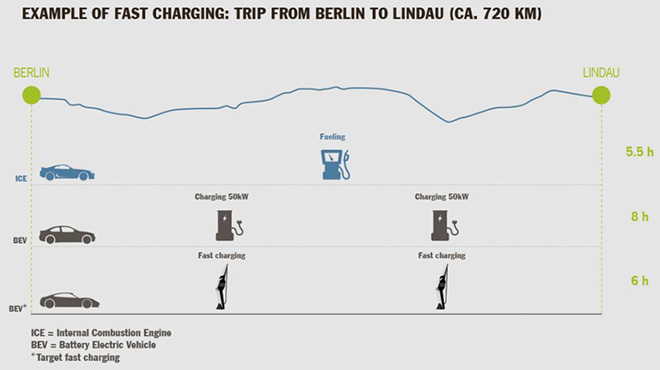

In a verbose recent article in Porsche Engineering Magazine, Volker Reber explains the benefits of higher charging levels, pointing out that current EVs require frequent recharging, and that, even with overnight charging, the range that is gained remains relatively small.

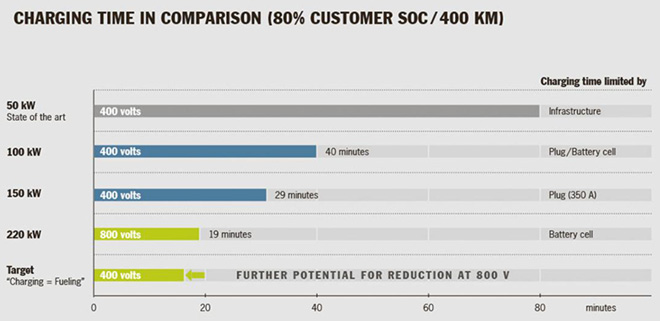

When it comes to long-distance driving, a rapid-charging infrastructure needs to offer a convenient ratio of driving time to break periods. “It should be possible to get a sufficient charge for roughly 400 kilometers within the usual break time of 15 to 20 minutes.”

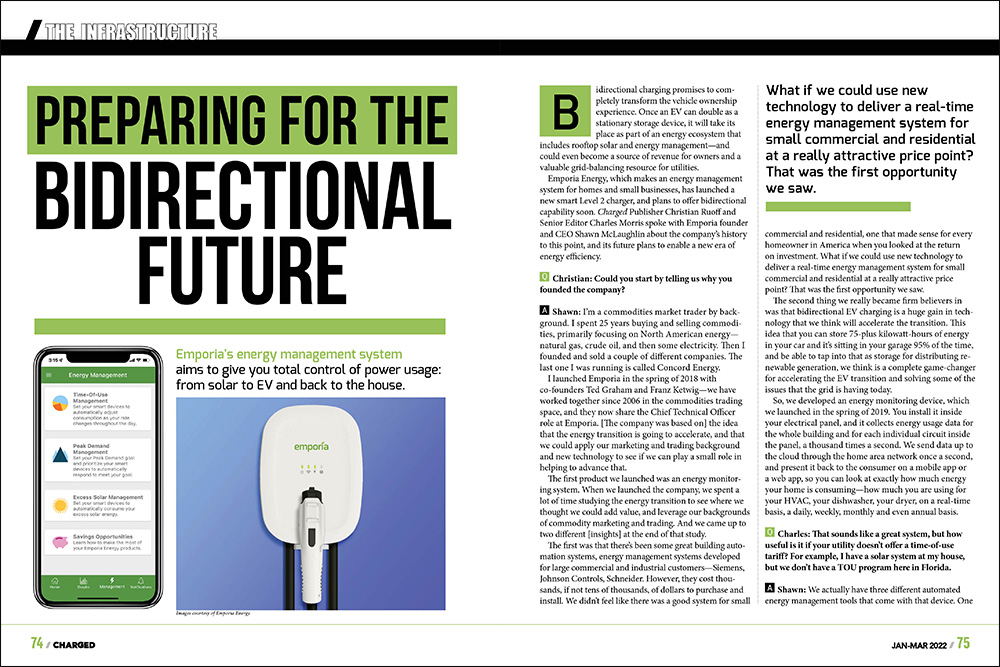

Charging time limited by mainly technical factors

Charging time limited by mainly technical factors

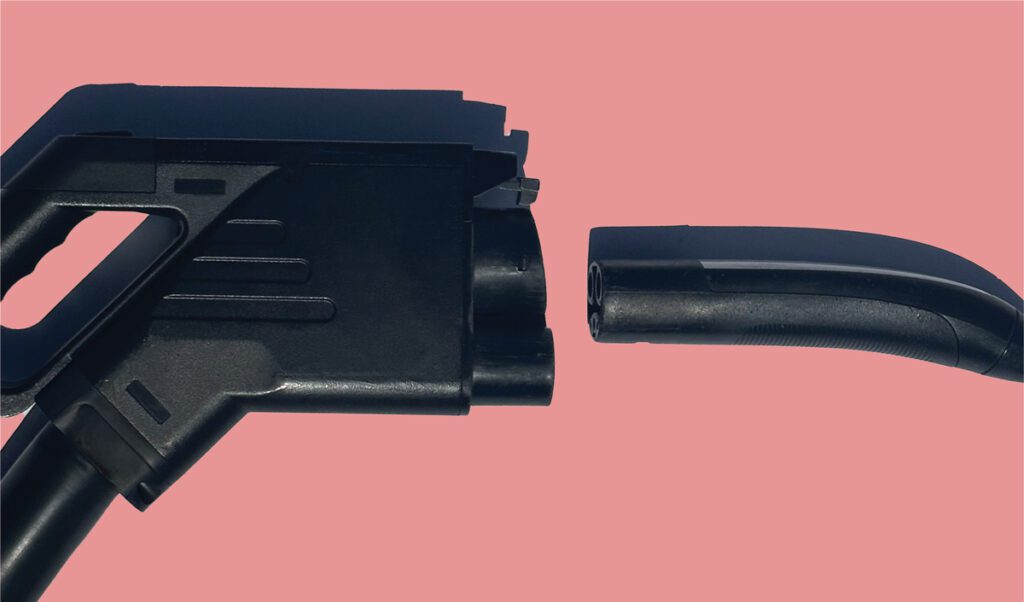

Unfortunately, technical factors currently stand in the way. Today’s DC fast chargers typically run at 400 volts, with 50 kilowatts of power. Even if charging levels could be increased, the capacity of the charging pins in the charging plug maxes out at roughly 100 kW, which still translates to about 40 minutes to add 400 km of range.

Further increases in charging power require some sort of cooling, and various companies are working on such systems.

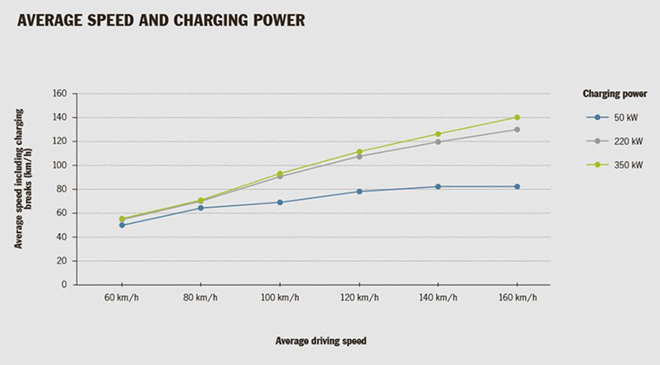

Achievable average speed in relation to the charging power

Achievable average speed in relation to the charging power

However, to get to the desired charging time, Mr. Reber finds that a shift to a higher voltage will be inevitable. Doubling the voltage to 800 volts could theoretically reduce charging time to about 15 minutes with the same electrical load on the charging pins, just enough time for a bathroom break and a quick snack.

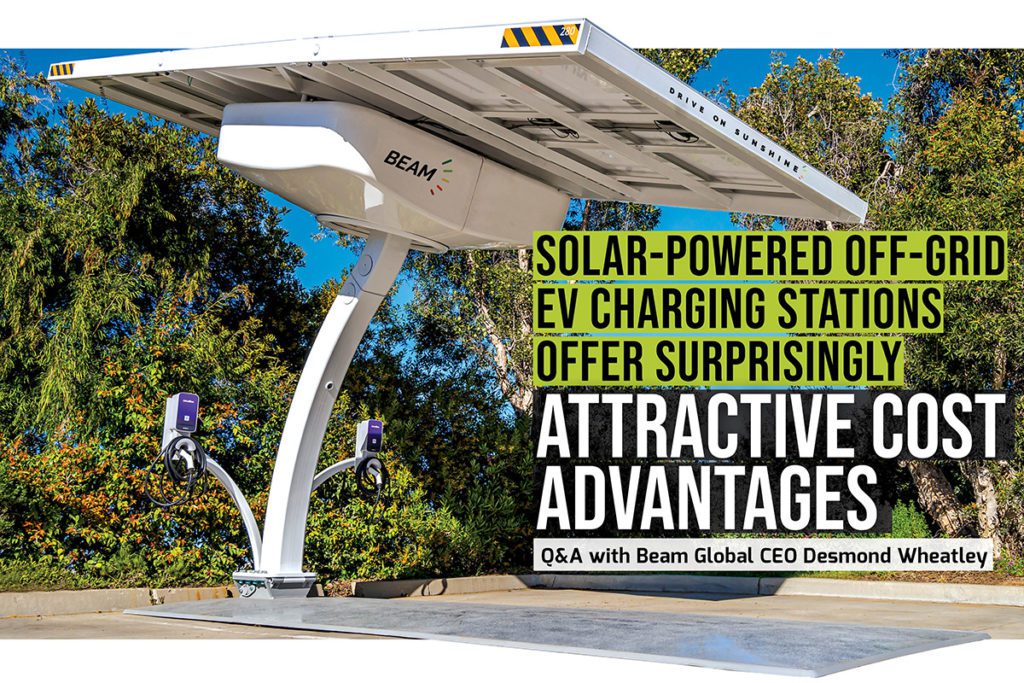

Faster charging would be good news not only for drivers, but also for station owners. The costs of installing charging stations are high. In terms of the price per kW, a higher-power charging infrastructure would be significantly more cost-effective (a recent blog from the Dutch charging station operator Fastned reached a similar conclusion).

Source: Porsche