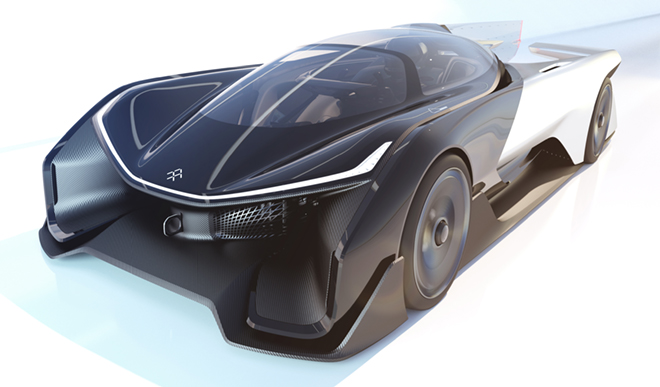

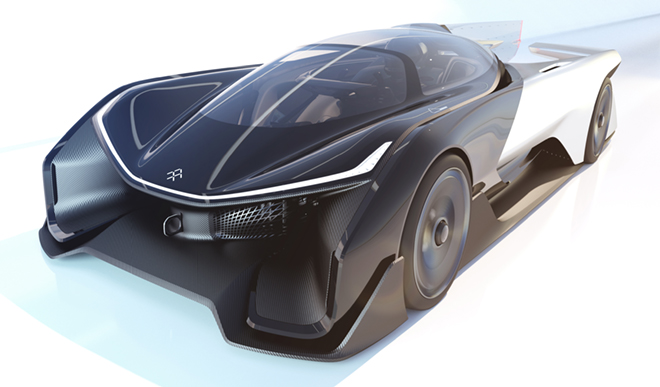

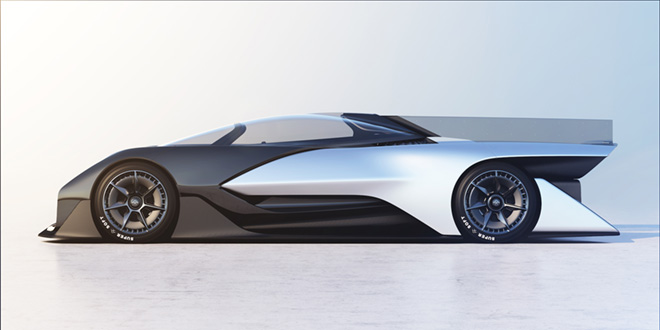

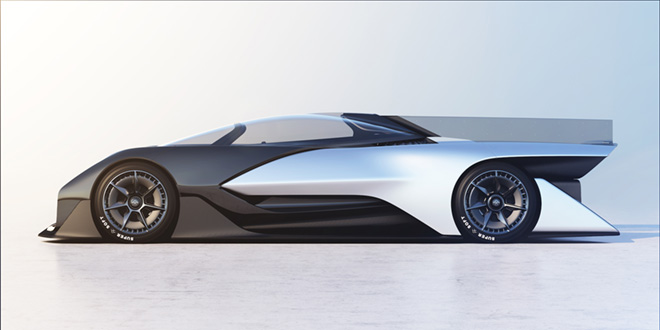

EV startup Faraday Future’s carmaking prowess has yet to be tested, but it has already revealed some impressive marketing talent. After milking several months of mystery, the company unveiled its FFZERO1 supercar concept at the recent CES in Las Vegas.

The event was one of the hottest tickets at a show that has reinvented itself as a venue for the latest automotive tech. By all accounts, the presentation delivered a healthy helping of hype, but a dearth of details about the company’s “complete rethink of what mobility means.”

The car itself is a single-seat racecar that more than one reporter compared to a Batmobile. It boasts 4 motors, with total power of 1,000 hp, a 0-60 time under three seconds, and a top speed over 200 mph.

Futuristic features include “aero tunnels” that run through the vehicle to reduce lift and cool the batteries, a steering wheel-mounted smartphone, several touch screens and augmented reality views that can be projected onto the road.

The company hopes to produce its first production vehicle by January 2018 – the media was shown a couple of images of a modern fastback utility vehicle. Senior VP Nick Sampson said that the production car will be something more practical than the FFZERO1 but still a premium-priced vehicle, perhaps a sedan or SUV.

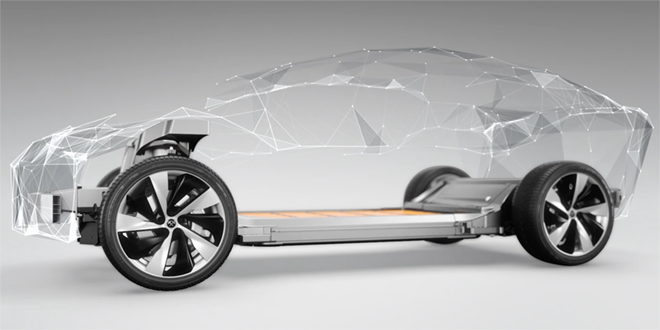

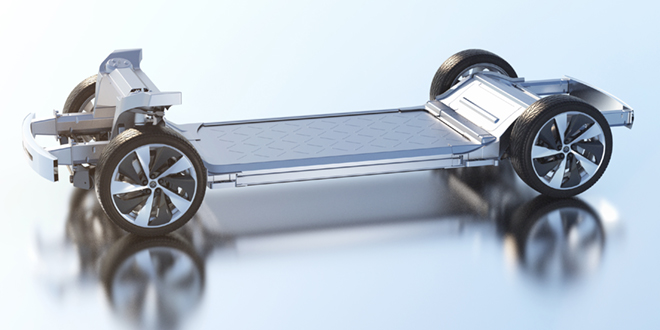

FF did provide some details about its Variable Platform Architecture (VPA), which underpins the FFZERO1 and will be used to build its production cars. The basic idea is a Teslaesque chassis with a flat battery pack that can be fitted with motors on one or both axles.

“The VPA will enable FF to minimize production costs, deliver exceptional quality and safety, dramatically increase its speed to market, and could easily support a range of vehicle types and sizes,” said Faraday in a press release.

“The skateboard-style chassis can be adjusted by changing the lengths of the rails and other relative structures to accommodate the number of battery strings per each configuration. There are structural benefits to the design as well, such as larger crumple zones that improve safety by centralizing and protecting the battery pack.”

“We can change the number and power of the drive systems,” Senior VP Nick Sampson told The Verge. “We can change the physical size and electrical size of the battery packs.”

Faraday spokesperson Stacy Morris compared the design of the battery pack to a Hershey bar: rows of batteries can be added for the desired capacity. The placement of motors can also be shifted for a front-wheel, rear-wheel, or all-wheel-drive vehicle.

Meanwhile, the company has committed to building a billion-dollar assembly plant outside Las Vegas that will cover 3 million square feet and eventually employ 4,500 workers.

Nevada lawmakers awarded FF a $335-million incentive package, a little over a year after Tesla scored a $1.3-billion haul for its Gigafactory.

The state’s wooing of EV companies seems more than a little ironic in light of the news that its Public Utility Commission has revised the state’s net metering rules to make rooftop solar less economical – so much so that SolarCity and other solar installers have announced plans to pull out of the state.

Sources: LA Times, BBC, The Verge, Gizmodo, Green Car Reports, Forbes