Sponsored by TTI and TE Connectivity

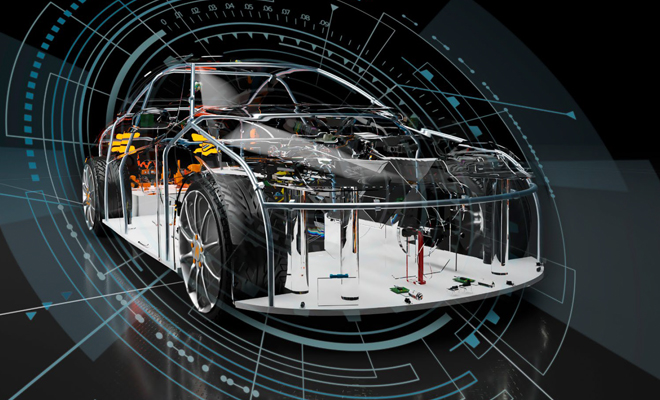

Automotive manufacturers have been building more electronic content into vehicles with powertrain electrification and increasingly sophisticated driver assist systems accelerating that trend. As a result, many sensor-driven control units with multiple printed circuit boards now have kilometers of new cabling and an exponential number of new connections all of which compete for space in dense car architectures. At the same time there is a growing trend towards light-weight components for greater fuel-efficiency and more environmentally friendly cars.

Manufacturers therefore need to find smarter electronic solutions that save space and reduce weight. Industry manufacturers are widely adopting miniaturized connectors inside vehicles, as wire sizes and packaging space within control units have been reduced. In some cases, so-called “black-box” components have included non-automotive miniaturized connectors. Their lack of robustness for automotive harsh environments have led to quality problems in a few modules and in certain cases component failures.

Automotive OEMs need to ensure that the sub-system modules they source are fitted with connectors that are truly automotive-grade – designed to comply with specifications and validation requirements such as LV214 (Europe) and USCAR2 (USA).

In this paper, we examine how manufacturers can achieve strategic space saving goals by using miniaturized connectors that provide true automotive-grade robustness. Specifically, we examine two of TE Connectivity’s miniaturized interconnection platforms for automotive applications; NanoMQS and MCON 0.50 interconnection systems – examining how they meet industry specifications, provide key technical advantages, and enable space saving of up to 50 percent. We also consider other factors contributing to the robustness of miniaturized components, such as small-wire crimp quality, and discuss how to address the increased risk of metallic whisker growth on high-density PCB pin connections.