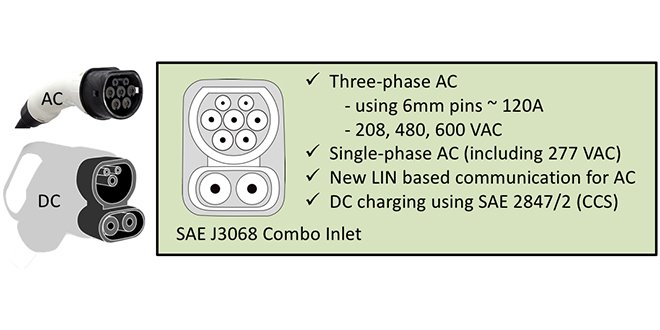

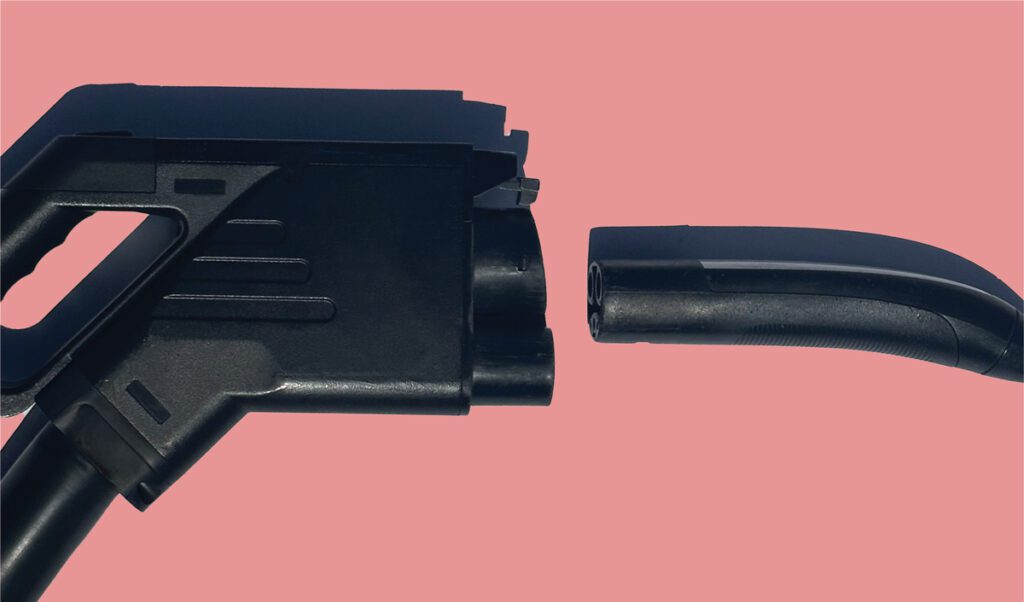

SAE International has published its recommended practice for plug-in charging of heavy-duty EVs. The new J3068 standard allows vehicles to fully utilize three-phase AC power.

Presenting a symmetric three-phase load enhances grid stability, especially at high power levels. SAE J3068 standardizes an AC three-phase-capable charging coupler and digital control protocols, offering sufficient power and reliability for the commercial vehicle market.

Existing technology is combined to provide higher power than existing charging solutions from the passenger car sector, with added diagnostics. DC charging on separate contacts with PLC controls is also described, as is limited three-phase AC charging with PWM controls, providing interoperability with J1772 protocols where possible.

SAE J3068 provides for:

- A higher-power version of an existing charge coupler, for example 133 kW at 480 VAC 160 A three-phase.

- Bidirectional digital communication between EV and EVSE via single-wire baseband signaling for local control.

- Grid supply voltage is signaled before the EV and Supply Equipment agree to charge. For example, in Canada 600 VAC is more common than 480 VAC but not all EVs can use 600 VAC.

- Independent control of current limits on a phase-by-phase basis. For example, this enables the minimum overall de-rate when only one phase leg has the available current restricted by the utility.

- The EV may signal requested current, to enable a power management system to balance loads better. A minimum power requirement communication option supports fixed loads such as refrigeration, which cannot control current draw other than in an on-or-off fashion.

“This new standard was designed to offer a single vehicle inlet solution for three-phase and single-phase AC and DC charging for a class of vehicles,” said SAE J3068 Task Force Chairman Rodney McGee. “We wanted to combine this new approach for AC charging with 1,000 V DC charging based on existing SAE communication standards.”

“The goals of J3068 include bringing a proven, mass produced three-phase charging coupler to North America, and establishing a low-cost, reliable communication and control protocol for AC with inherently high interoperability,” said Document Sponsor Jim McLaughlin. “High-power AC charging has cost advantages in many use cases, and three-phase charging simplifies balancing of the power grid.”

Source: SAE International