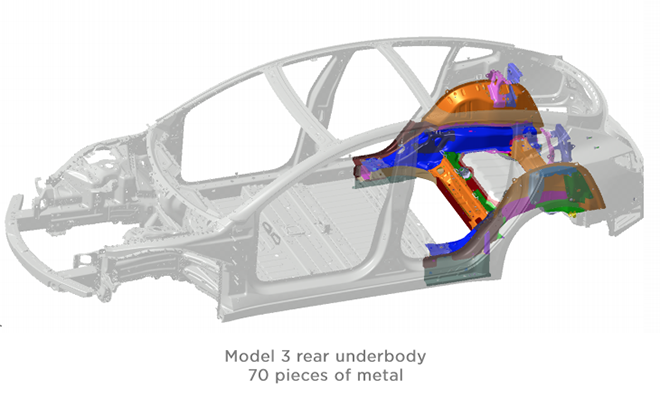

Tesla is constantly working to simplify the manufacturing process for its vehicles. Last year the company applied for a patent on a new casting machine that would be used to build Model Y. “When we get the big casting machine, it’ll go from 70 parts to 1 with a significant reduction in capital expenditure on all the robots to put those parts together,” said Elon Musk.

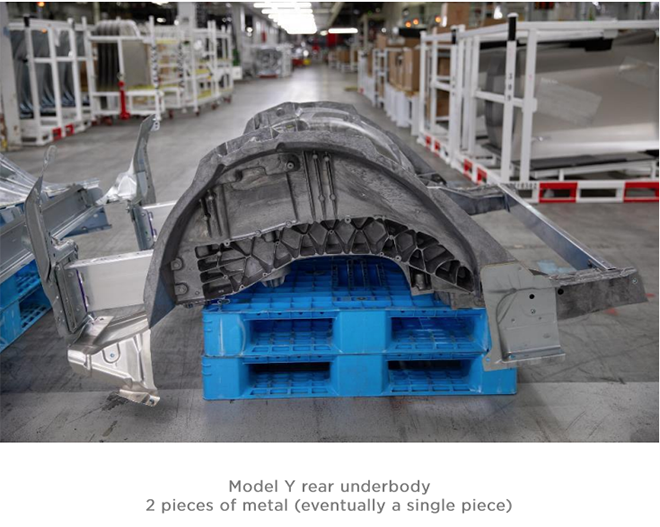

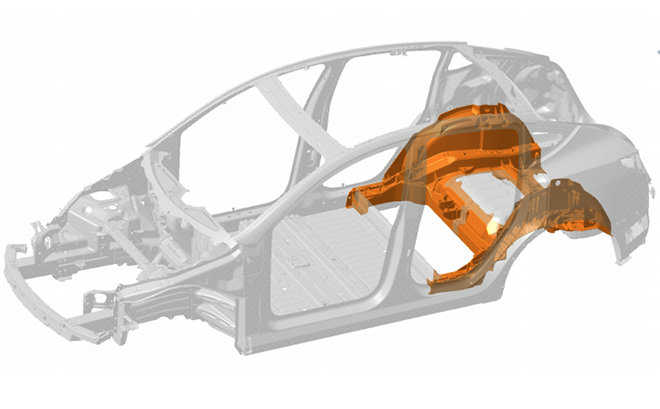

Now Tesla has released images of the results. Diagrams show Model 3’s underbody, which is made up of 70 stamped steel and aluminum parts, and Model Y’s underbody, which consists of just two huge hunks of cast aluminum. (Sandy Munro also gave us a look at the innovative new parts in his recent Model Y teardown.)

In the Q1 earnings conference call, Musk called the new casting procedure “revolutionary”—no overstatement, considering the amount of time and money it must save—and said that more advances are in store: “We are going to be making a single-piece casting later this year, meaning…the rear third of the body is cast as a single piece. There is no casting of the size and complexity that has ever been done before.”

Tesla plans eventually to use the same casting technology on its other vehicles—a change that will surely require a major revamping of the production line—but has not mentioned a timeline.