Electric buses and trucks are coming. In June, the California Air Resources Board instituted a zero-emission mandate for truck sales—manufacturers must make zero-emission trucks at least 30% of sales by 2030. Following that announcement, 15 states plus DC have said they want all new trucks to be electric by 2050.

Granted, such measures are best described as aspirational—the requirements are vague and the timelines are timid. But they do indicate which way the wind is blowing, as real-world anecdotes accumulate. In July, Charged reported on new e-bus deployments in Finland, Germany, Chile, Alberta, and California—and these were only a fraction of the stories that came across the wire. Motiv is powering electric box trucks in Sacramento (among other cities), Hyundai’s delivering fuel cell trucks in Switzerland, Volvo’s piloting e-trucks in California, and Nikola hopes to deliver as many as 5,000 electric refuse trucks over the next few years.

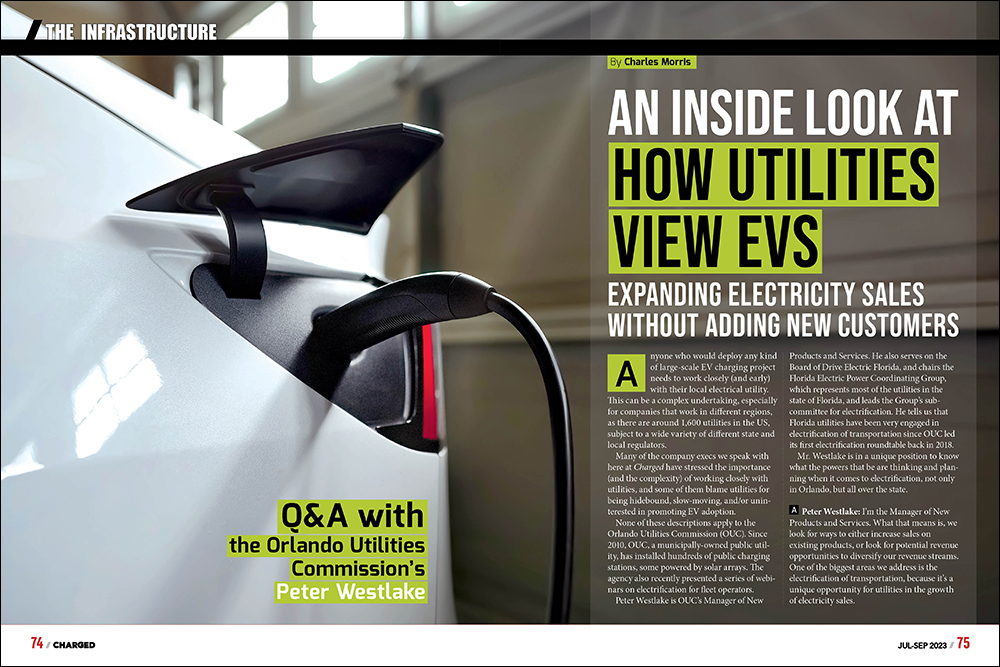

Are utilities going to be ready to supply the massive amounts of power that will be needed for electric fleets? A recent article by the nonprofit American Council for an Energy-Efficient Economy (ACEEE) finds that, while some utilities in California and elsewhere are planning for an increase in power demand, most have a long way to go.

Providing sufficient power is more of an issue for trucks and buses than it is for passenger cars, not only because of the formers’ much larger batteries, but also because fleets are likely to have many vehicles charging at the same location.

Some examples: a Tesla Model 3 battery has a capacity of 54-75 kWh, whereas a Proterra transit bus battery stores 220-660 kWh.

In Amsterdam, a 100-bus transit fleet is powered by a combination of slow and fast chargers that together have a peak load of 13 MW, equivalent to the power used by a large factory. The fleet is eventually scheduled to expand to 250 buses.

When Amazon starts electrifying, a fleet of 200 delivery vans at one fulfillment center might draw around 4 MW. Electric Class 8 trucks may need up to 2 MW of power each. A proposal from the West Coast Clean Transit Corridor Initiative calls for installing charging stations every 100 miles along the I-5 corridor, each with a peak load of 23.5 MW.

That’s a lot of juice—much more than most utilities will be able to provide without substantial planning and investment, as the ACEEE points out. Meeting the power demands will require upgrades to primary and secondary power distribution systems and substations. For large loads, a new substation may be needed.

A recent paper from the California Electric Transportation Coalition estimates that, for loads over 5 MW, distribution system and substation upgrades will typically be needed, at costs ranging from $5,000-100,000 for secondary distribution upgrades to as much as $9 million for substation upgrades.

As usual, California utilities are leading the way. The state has been funding various demonstration projects, and providing incentives for vehicle and charger purchases, for several years. Several California utilities are working with fleet owners to install the necessary EVSE.

Southern California Edison’s Charge Ready Transport program for medium- and heavy-duty fleets waives the usual fees for new or upgraded service, and in some cases chips in on the cost of chargers. SCE has 24 commitments so far, and has set a 5-year goal of 870 sites, with an average of 10 chargers per site. The utility notes that load management measures, including smart charging and stationary storage, can reduce capacity needs by as much as 50%.

Source: ACEEE

Image: Volvo Trucks