Success stories sometime spring from unlikely places, especially during times of rapid, disorienting technological change. Consider the case of Tritium, a small independent company based in Australia, half a world away from the centers of automotive power, that has grown to become one of the world’s leading manufacturers of DC fast chargers.

When asked about the progress of electromobility in his home country, Tritium’s Sales Manager Marcelo Salgado, didn’t mince words. “Australia’s EV market is very poor,” Salgado told Charged. “We’re a good 5 years behind the rest of the world. At the moment we only have 3 plug-in vehicles, so there aren’t enough cars available, and there’s no government support.”

The lack of opportunities at home has inspired Tritium to reach out around the world, and today it’s selling in some 20 countries, including such remote markets as Sri Lanka and Kazakhstan. “We literally have product on every continent, including Antarctica, where we’re driving a telescope for a university,” says Salgado.

Tritium was founded 15 years ago by the 3 directors, David Finn, James Kennedy and Paul Sernia, who started out developing EV motor controllers.

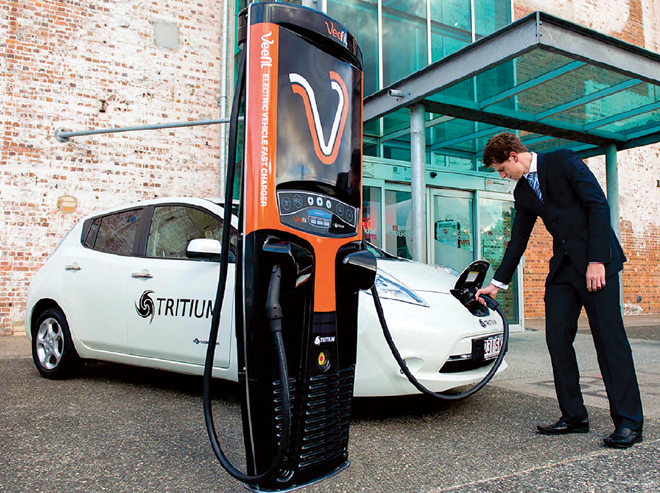

About 3 years ago, Israeli startup Better Place approached Tritium to develop a charger, and that was the genesis of the company’s signature product, the Veefil. Since then, Tritium has focused on EV charging, although it continues to sell its motor controllers, mostly to solar racing teams. “We have about 90% of the solar race teams using them,” says Salgado. “We’re big supporters of the solar racing industry, so we will keep making our WaveSculptor Motor Inverter products for those markets.”

Cool in more ways than one

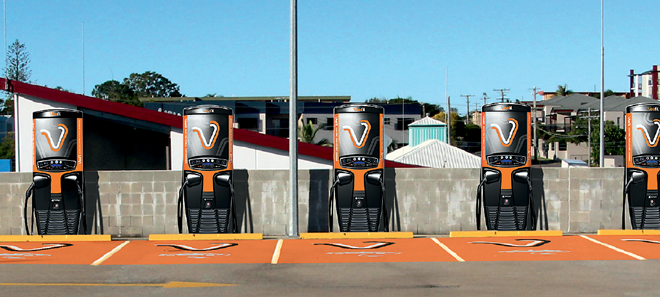

One thing that sets Tritium apart from other EVSE manufacturers is the attention it pays to aesthetics. Whereas many chargers are nondescript white boxes, the Veefil is slim and curvaceous, is available in a variety of bright colors, and can be fully customized with a customer’s own branding. In 2014 it won the Good Design Australia Award in the Automotive and Transport category.

However, it isn’t designed for looks alone. Its slim form factor gives it an extra-small footprint and light weight, which Tritium says will enable it to be installed in more locations than other chargers.

Salgado is convinced that the company’s great product design is the key to its sizable share of the global DC fast charger market. “The Veefil is probably the first product that was designed specifically for EV fast charging. I think a lot of our competitors got parts off the shelf and stuck them in a box. We have a market-leading product line because our products look great, they’re easy to install, and they have a very small footprint thanks to our use of liquid cooling.”

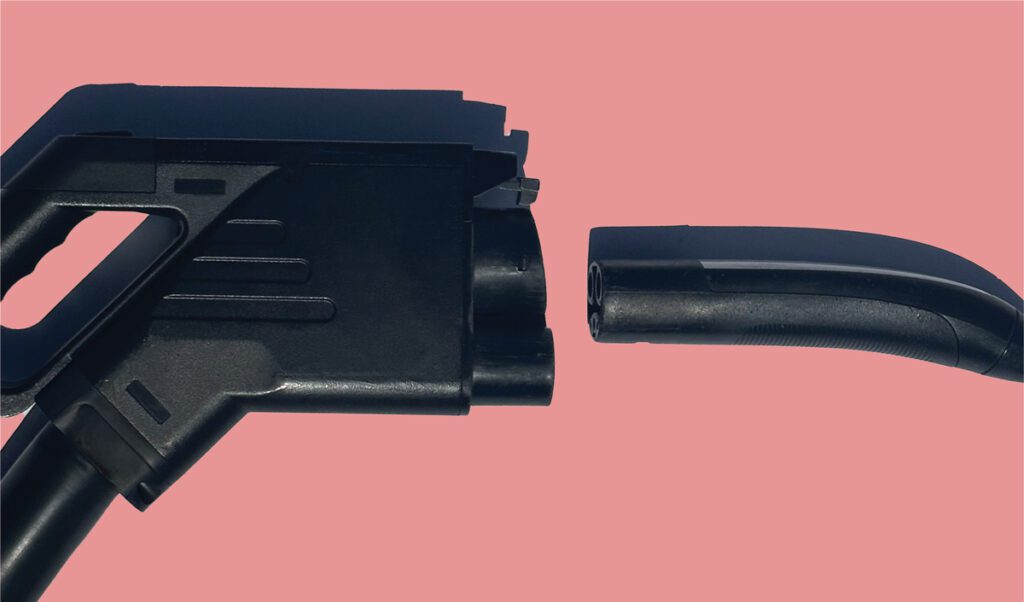

Liquid cooling delivers several advantages. “The Veefil was designed from the beginning as a liquid-cooled charger, which allows us to make a slimmer, sleeker product compared to our competitors, and it also helps with a reduction in maintenance and increases reliability because we’re dealing with the heat a lot better. Our power electronics are a lot happier when the overall operating temperature is reduced.”

Veefil chargers support all the major charging standards: CHAdeMO, CCS types 1 and 2, and GBT. Products sold in the US market offer a choice of CHAdeMO, CCS, or both.

Conquering Europe and America

Most of Tritium’s market is in Europe and North America, with a roughly equal split between the two at the moment.

Chargepoint has been the exclusive US distributor for the Veefil, which is sold under the Chargepoint Express 200 brand. Part of Tritium’s expansion strategy for 2017 is to grow its re-seller network across the US, and it’s looking for potential partners who are interested in the opportunity.

Tritium recently opened an office in Torrance, California. “This facility will become our sales and support office to support our existing customers, and we’ll do a bit of R&D and then some local manufacturing,” said Salgado. “We will continue to expand our manufacturing capabilities in the US over the next couple of years, so this will be our second manufacturing facility. And we’ll scale it to a much larger facility in the future.”

Europe is also a major market. “We have really strong market share in Norway. We’re supplying Fortum, which is the largest network operator there, and others as well.” Tritium is also expanding into the UK, Germany and Belgium.

New Veefils

Tritium has recently introduced 2 new models, which will be available in the States near the end of this year.

The Veefil-WP 12 kW DC ground-mounted charger is “specifically designed for fleets and workplaces where you would have a situation with more than one charger installed in the same location, so they can communicate together.” Its price point is meant to be competitive with that of a fast AC charger.

The Veefil-UT 50 kW DC is designed to be connected directly to a power line. “It was designed with a utility, and it has what we call a backpack box where you can put the meter, switching and safety gear in the backpack and actually connect it directly to the power line.”

Higher and higher

With a new generation of power-hungry long-range EVs on the horizon, charger manufacturers are developing new models with higher voltages and higher currents, and Tritium is no exception. “We’re currently in the prototype phase of the next-generation Veefil – that will be our 100 to 500 kW charging solution,” says Salgado. “Again, we’re taking a very different approach to the power electronics. We won’t be doing what the rest of the market is doing – sticking power modules in a cube and hiding them in the bushes.”

Tritium aims to have the new product certified and available to buy in the second quarter of this year. “It’s going to give customers flexibility. You’ll have multiple heads, so from the one source you can have a 350 kW head and a 100 kW head. And they will get along with load sharing and all that kind of fun stuff.”

This article originally appeared in Charged Issue 30 – March/April 2017 – Subscribe now.