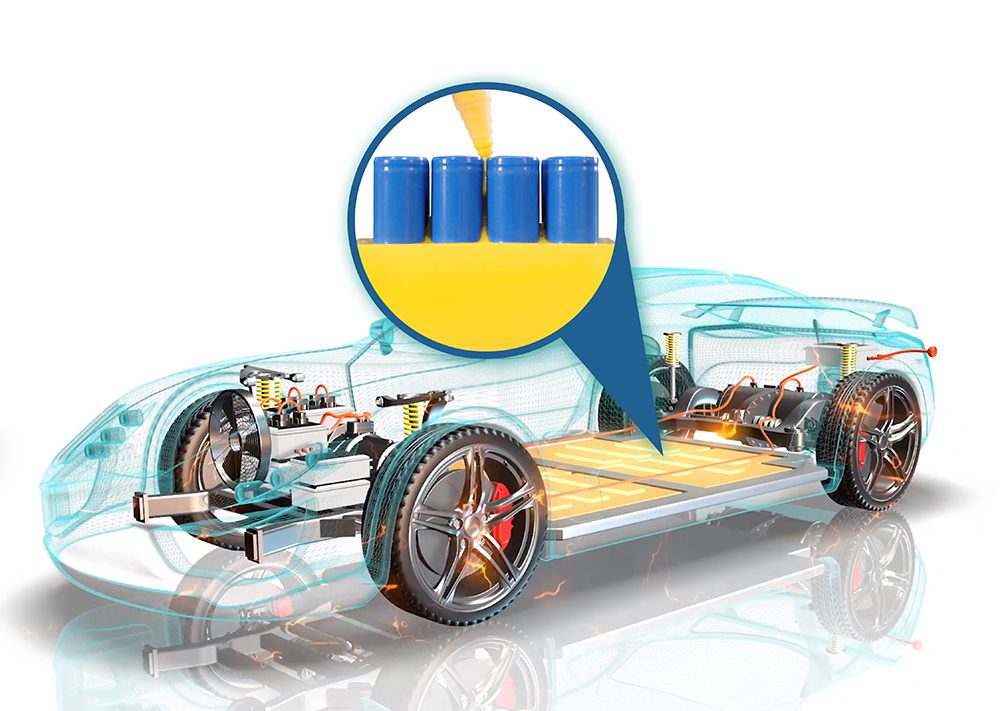

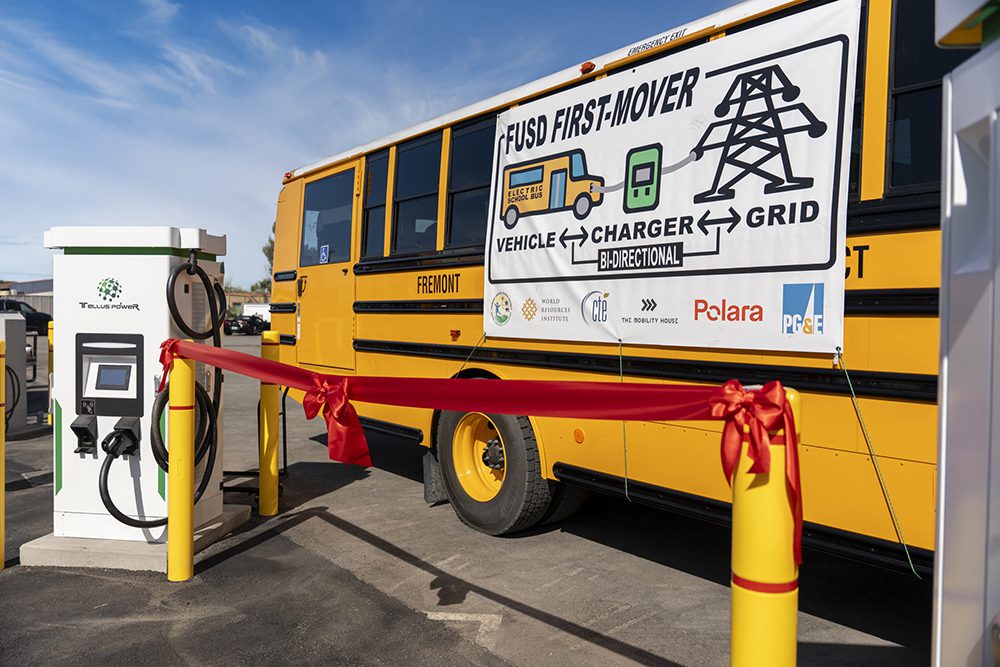

Nanotech specialist Xtalic Corporation has created alloys and coatings that increase battery connector lifespans from 250 charge cycles to 10,000 at temperatures of 150° C and above. In order to do this, the company places certain elements in its primary material’s grain boundaries to create alloys with higher stabilities at various temperatures and accurately controlled grain sizes. This precision allows Xtalic to provide both graded options and stack solutions to customers.

XTRONIC and LUNA alloys are two of Xtalic’s most significant developments. XTRONIC is a nanostructured nickel alloy that has a Vickers hardness number (HV, a measurement of a material’s resistance to deformation by indentation) of over 650. It is designed to extend connector lifespans and reduce precious metal costs. To control its grain sizes and stabilize its grain boundaries, XTRONIC has been infused with tungsten. LUNA is a silver alloy that also uses tungsten and has an approximate hardness of 200 HV. It closely mimics the electrical properties of hard gold. Xtalic’s latest project is the development of XTALIUM, a durable corrosion-resistant aluminum alloy coating that allows light, cost-efficient magnesium to be used in automobile components.

“As more electric-powered vehicles take to the highways, the life expectancy of their battery charging interfaces are becoming critical,” said Xtalic CEO Tom Clay. “Extending the lifecycle of the charger’s connector contacts has become an important customer satisfaction issue for electric vehicle manufacturers.”

Source: Xtalic via Green Car Congress