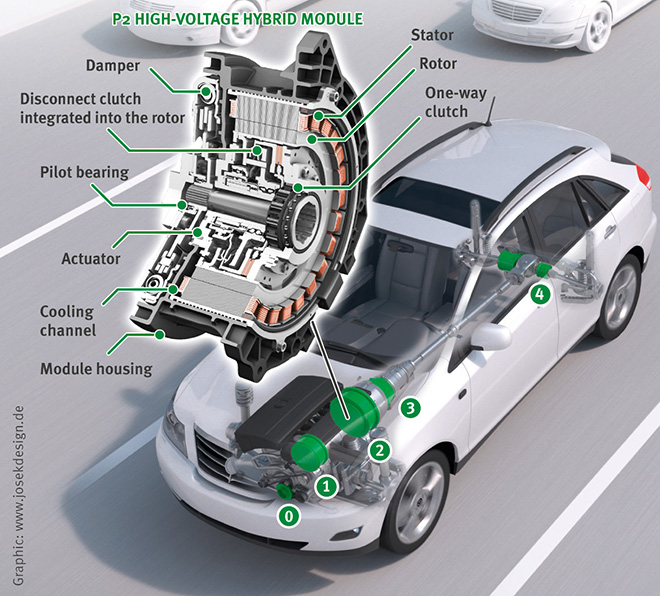

Schaeffler has developed a new P2 (parallel, two-clutch) high-voltage hybrid module -designed to fit between the internal combustion engine and transmission – that can transmit engine torques of up to 800 N·m (590 lb-ft) without having to incorporate an expensive clutch.

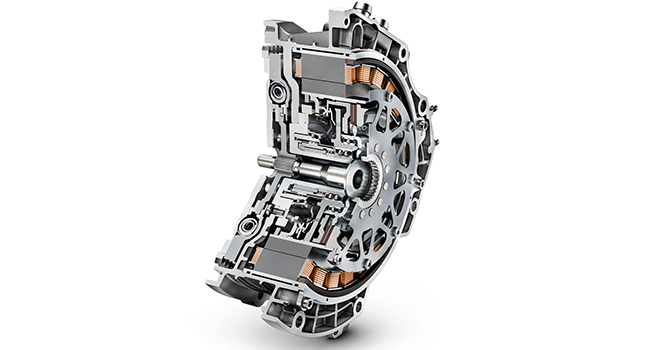

The P2 consists of an electric machine and an automated disconnect clutch, which is operated by an electromechanical central clutch release system that engages the clutch mechanically via a ball screw drive without a hydraulic transfer path.

The pathway of torque conveyance depends on its direction: torque is transmitted to the crankshaft via a 300 N·m disconnect clutch, while traction torque from the internal combustion engine is transmitted to the transmission via a one-way clutch. This allows a compact design, which can save on space and cost.

Regulating the connection to the engine when accelerating is normally a complicated matter that involves the gas engine, the disconnect clutch, the electric motor, and the transmission. The one-way clutch provides an immediate mechanical connection to the engine as soon as the engine and electric motor speeds synchronize, allowing regulation to take place more quickly.

The new hybrid module will go into volume production in China in 2017.

Source: Schaeffler via Green Car Congress