Who knew? The miracle material that could enable a game-changing battery breakthrough is (drumroll, please)…beach sand.

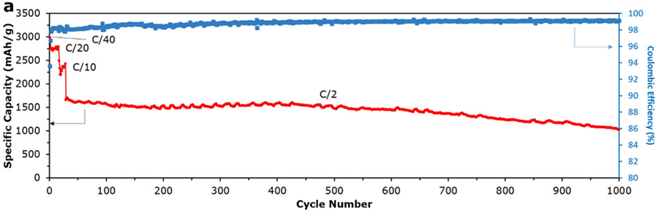

Researchers at the University of California Riverside have created a lithium-ion battery that outperforms the current industry standard by three times, using a nanoscale silicon dioxide anode.

“This is the holy grail – a low cost, non-toxic, environmentally friendly way to produce high-performance lithium-ion battery anodes,” said Zachary Favors, a UC Riverside graduate student and co-author of a new paper, Scalable Synthesis of Nano-Silicon from Beach Sand for Long Cycle Life Li-ion Batteries, published in the journal Nature Scientific Reports.

A number of scientists have explored the possibility of replacing graphite with silicon as a material for anodes, but so far, most have found that nanoscale silicon degrades quickly and is hard to produce in large quantities.

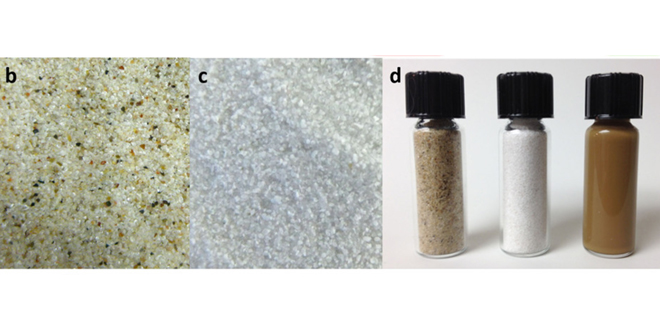

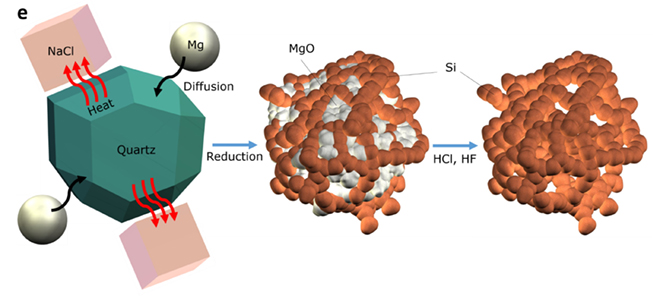

Favors set out to solve both these problems. He found a variety of sand that contains a high percentage of quartz, and milled it down to the nanometer scale, followed by a series of purification steps, ending up with a material that looks like powdered sugar.

He then ground salt and magnesium into the purified quartz, and heated the resulting powder. With the salt acting as a heat absorber, the magnesium worked to remove the oxygen from the quartz, resulting in pure silicon.

The pure nano-silicon formed in a very porous 3D sponge-like consistency. According to the research team, that porosity enables them to build batteries with an expected lifespan, and energy density, three times higher than those with traditional graphite-based anodes.