Canada-based Mkango Resources has teamed with UK-based Metalysis to develop and commercialize novel rare earth metal alloys for use in 3D-printed permanent magnets.

The two companies envisage a comprehensive R&D program, taking advantage of Mkango’s knowledge about the performance characteristics and demand outlook for rare earth magnets and Metalysis’s solid-state process, which it says can generate high margins from the manufacture of metal powders.

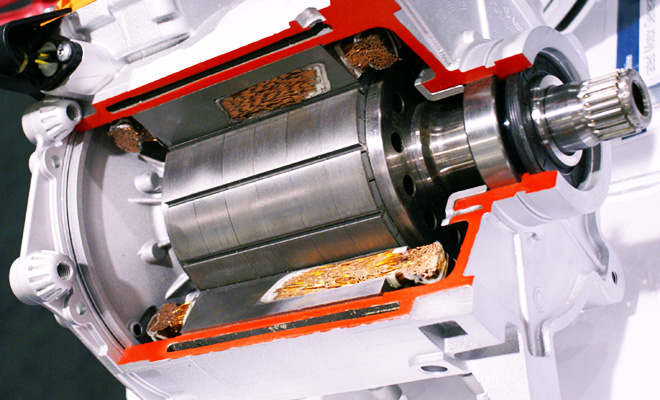

Rare earth permanent magnets are a critical component of many EVs. China currently dominates the rare earth permanent magnet industry, and Mkango has one of the few rare earths projects outside China to have advanced beyond the pre-feasibility stage. The company is exploring for rare earth elements and associated minerals in the African nation of Malawi, where it hopes to exploit deposits of carbonatite-hosted rare earths, niobium and tantalum.

Metalysis has a patented process, which has been proven at industrial scale, for producing titanium, tantalum, other metals and innovative alloy powders for markets including 3D printing.

“It is a core part of Mkango’s strategy to be at the forefront of research and technology in every step of the rare earths supply chain; positioning the company as a future low-cost, sustainable supplier of rare earths used in electric vehicles,” said Mkango CEO William Dawes.

Source: Mkango via Green Car Congress