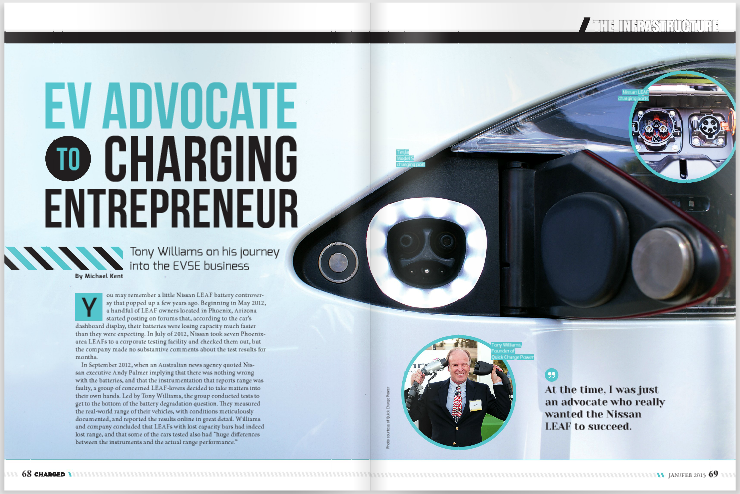

EV advocate to charging entrepreneur

You may remember a little Nissan LEAF battery controversy that popped up a few years ago. Beginning in May 2012, a handful of LEAF owners located in Phoenix, Arizona started posting on forums that, according to the car’s dashboard display, their batteries were losing capacity much faster than they were expecting. In July of 2012, Nissan took seven Phoenix-area LEAFs to a corporate testing facility and checked them out, but the company made no substantive comments about the test results for months.

In September 2012, when an Australian news agency quoted Nissan executive Andy Palmer implying that there was nothing wrong with the batteries, and that the instrumentation that reports range was faulty, a group of concerned LEAF-lovers decided to take matters into their own hands. Led by Tony Williams, the group conducted tests to get to the bottom of the battery degradation question. They measured the real-world range of their vehicles, with conditions meticulously documented, and reported the results online in great detail. Williams and company concluded that LEAFs with lost capacity bars had indeed lost range, and that some of the cars tested also had “huge differences between the instruments and the actual range performance.”

“At the time, I was just an advocate who really wanted the Nissan LEAF to succeed,” Tony Williams told Charged. “We tried to do our tests as openly as we could, because we wanted to show everyone that there was a real problem that needed to be fixed.”

The whole issue was put to rest when Nissan took several steps to mitigate any technical or public relations problems, including: establishing an independent “LEAF Advisory Board” to improve communications with customers (including Williams as a charter member); buying back a couple of LEAFs that had lost capacity; announcing a 2013 LEAF with a new and improved battery; and upgrading the LEAF’s warranty to cover capacity loss.

Before the battery brouhaha, Williams spent his free time helping to roll out DC Fast Charging infrastructure. When he wasn’t busy at his full-time job – an aviation professional and airline pilot for nearly 30 years – he worked to install the very first DC Fast Charger on the ChargePoint network in San Juan Capistrano, California. “It’s one of the busiest, if not the busiest,” said Williams, who is a part owner of the station. “We’re over 4,000 paid charge events now.”

“My interest at the time wasn’t to be in business, to be honest. I had a LEAF, and I wanted to help it succeed, because I thought it was the car that was going to lead the way. It was a lot of legwork to get that first charger installed. But we got it done, and I’m very proud of that.”

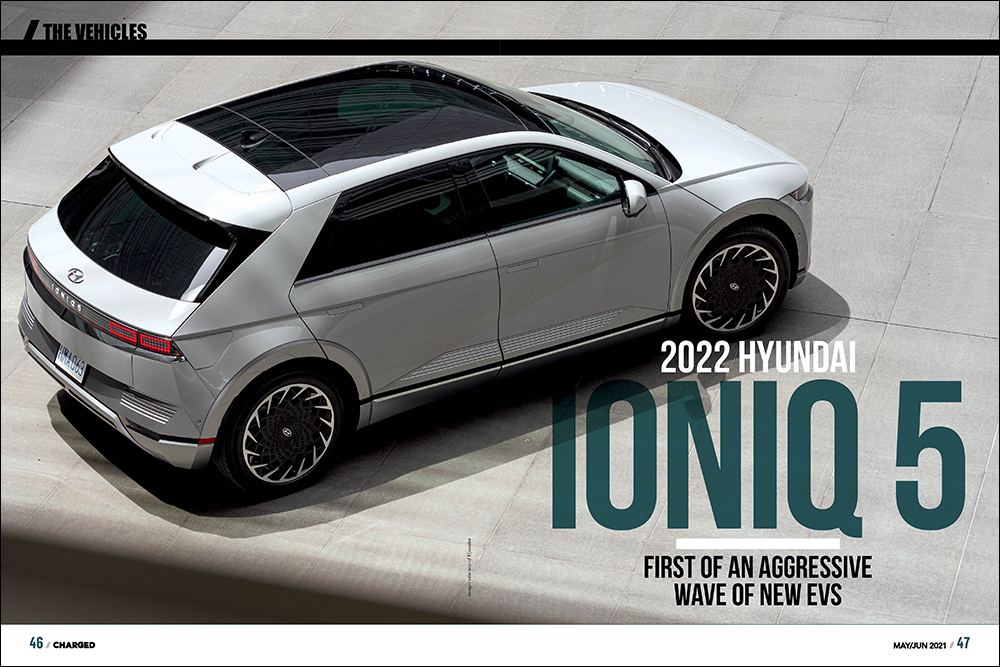

In the aftermath of the LEAF battery controversy, however, Williams says he was “a little frustrated with Nissan,” and decided to buy a Toyota RAV4 EV.

JESLA – a company is born

The second-generation RAV4 EV – released September 2012 in limited quantities in California – has a battery and powertrain built by Tesla. Like the Model S, the RAV4 EV is equipped with a high-power onboard charger, relative to other EVs on the market. At 10 kW, Williams says he had trouble finding a portable 40 A Level 2 charging station that could deliver the fastest possible charging speed.

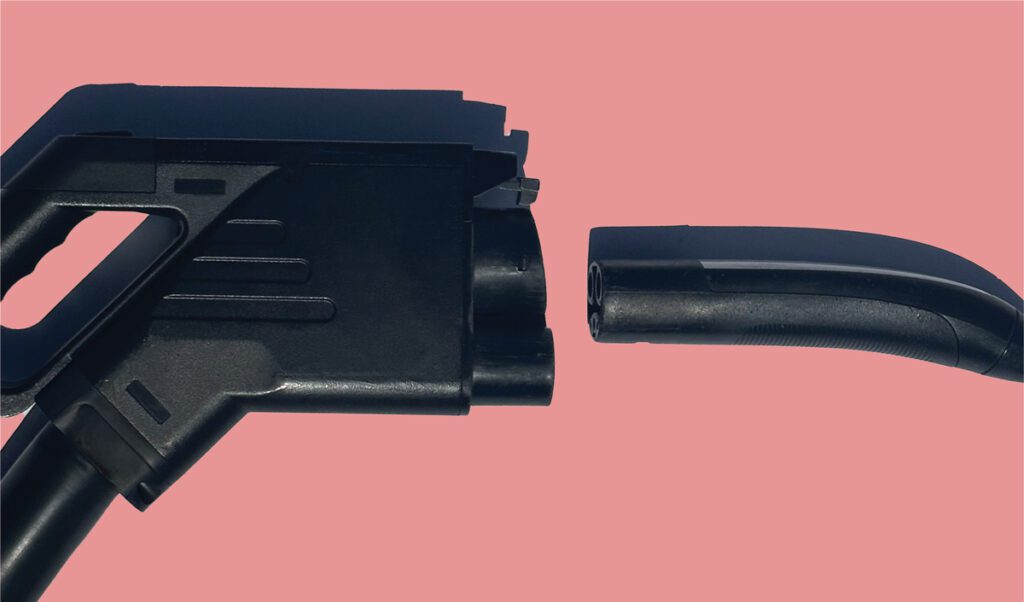

“There were a couple options for a 40 A J1772, but they were big, clunky, not very portable, and very expensive,” he said. “I knew that the RAV4 had a Tesla-designed onboard charging system so I thought there was no reason that the Tesla Model S mobile charging connector wouldn’t work.”

Tesla’s Mobile Connector Bundle, supplied with the Model S, will automatically adjust the current up to 40 A by switching between one of five plug adapters (NEMA 5-15, 5-20, 10-30, 14-30 or 5-20). The unit is very compact and portable, and the company was selling them for around $700 – far cheaper than other 40 A EVSE at the time. The problem, however, was that it uses Tesla’s proprietary charging connector. So, Williams bought one, hacked off the handle, wired up an SAE J1772 connector, and the rest is history.

“I didn’t know for sure that it would work,” he said. “It was a leap of faith and ended up working perfectly. So, I built one for my RAV4 and thought, ‘If I could sell a few more of these it would pay for itself.’ I put out a call on the internet and sold ten quickly. Then ten became 100 and the business was started with that product.”

Tony and his brother Bob went on to found Quick Charge Power LLC to sell charging equipment through its online store at www.QuickChargePower.com.

Securing a steady supply of Model S chargers to convert to J1772 was not easy, because Tesla is not used to supporting retail customers other than its vehicle owners. “A friend who owns a Model S helped me buy the first one,” said Williams. “But then to buy them in large quantities was a real pain in the neck sometimes. There were times when I could source them easily and times when I couldn’t. Today I’m able to order larger quantities online and have them drop-shipped, without any issue.”

JAMP – necessity breeds invention

At one point, Tesla stopped producing its charge cord as it rolled out a redesigned version, and Williams was left with steady demand but no supply. During that dry period, it wasn’t clear that he would ever be able buy more of Tesla’s chargers. So, naturally, he began a yearlong design process to build his own J1772 charge cord, dubbed JAMP.

The first in the JAMP product line of EVSE is the JAMP JR, due out March 1st. “The JESLA is great, but it’s kind of expensive because we have to buy the unit from Tesla at retail prices, before it’s modified,” said Williams. “And there is still uncertainty about our future supply. So, we’re going to offer the JAMP JR as a simple, low-cost, portable 40 A solution. You just plug it into a 50 A outlet and it provides 40 A, or the maximum that your car will accept.”

At 40 A, the JAMP JR will be able to charge every EV currently available in North America at its fastest possible Level 2 rate, except the Tesla Roadster and Model S with two onboard chargers. The ultimate goals are affordability, full power, and high quality. Williams says that the company is pushing to be the lowest-cost 40 A J1772 charging solution, and at the planned retail price of $499, it will be.

The JAMP JR will also be available in lower-power versions, beginning at $299, which will capture the moniker of lowest price Level 2 EVSE available anywhere. And by the end of the year, Quick Charge Power plans to offer the JAMP SR – a wall mounted unit that will cover power ranges between 41 A and 80 A.

“All of our products are made in the US, assembled in Washington State,” boasts Williams. “Most of the components, like the cables, are made in California. And the handles are built right here in San Diego county. Right down to the circuit boards, which most people farm out overseas, we build right here in California. We’re pretty proud of that.”

JLONG – in a pinch

Williams has been driving EVs for about 4 years, including two Electric Vehicle rallies from Mexico to Canada dubbed “BC2BC.” This has put him in a position to use a lot of public charging infrastructure and noticed one very common problem: the charging station cord is often too short.

“When you come to a charging spot it’s often blocked, or the last guy left his EV there, or you just can’t reach because your charge port is in the rear – like with the RAV4, BMW i3, Mercedes B-Class, and Tesla Model S,” said Williams. “The number-one problem with charge ports in the rear is when you pull into angled parking spots with a charger on the curb. Often, the cord will barely reach, or it won’t at all, and turning the car around to back it in on a busy street is nearly impossible.”

In these cases, Williams realized that a J1772 extension cord would be invaluable. So he created one, called it JLONG, and started selling it. It’s one of those products, like jumper cables or a spare tire, that when you need it, you really really need it. The unfortunate truth is that when a driver needs to charge away from home, the competition is not only other EVs, but also gas cars that want to use the charging spots for parking. The JLONG helps to satisfy this really basic need. “I’ve seen some really nutty stuff out there with people stretching cords to the limit,” said Williams.

As it turns out, many EV drivers have also realized its value, and Williams reports that it’s been very successful. “It saved my bacon quite a few times, and I’ve heard a lot of similar stories from our customers. We sell quite a few of them.”

Currently, the JLONG is available in any customized length, but Williams told us that the company will begin to standardize it to help meet high-volume demands. Personally, he carries a 40 ft extension. “The standard car is about 20 ft long, plus or minus a few feet. So, I found that you need 40 ft just to be comfortable.”

Charged full-time

In 2014, Tony spent most of the year shuttling between Europe, North Africa and the Middle East as an airline pilot, while Bob ran the daily operations of the business. With the launch of the JAMP JR, both Williams brothers are now focused on the company full-time. This year will bring a marketing push for the newest products, partnership discussions for rebranding and wholesaling, and the continual development of what’s next.

The path from EV enthusiast to entrepreneur has led Quick Charge Power into an EVSE market with competition from a number of giant international conglomerates. To succeed, the company will have to continue to do what it does best: immerse itself in the grass-roots EV culture and deliver products that improve the experience of the everyday driver.

MORE: Quick Charge Power to offer CHAdeMO DC Fast Charging upgrade for Toyota RAV4 EV

This article originally appeared in Charged Issue 17 – January/February 2015