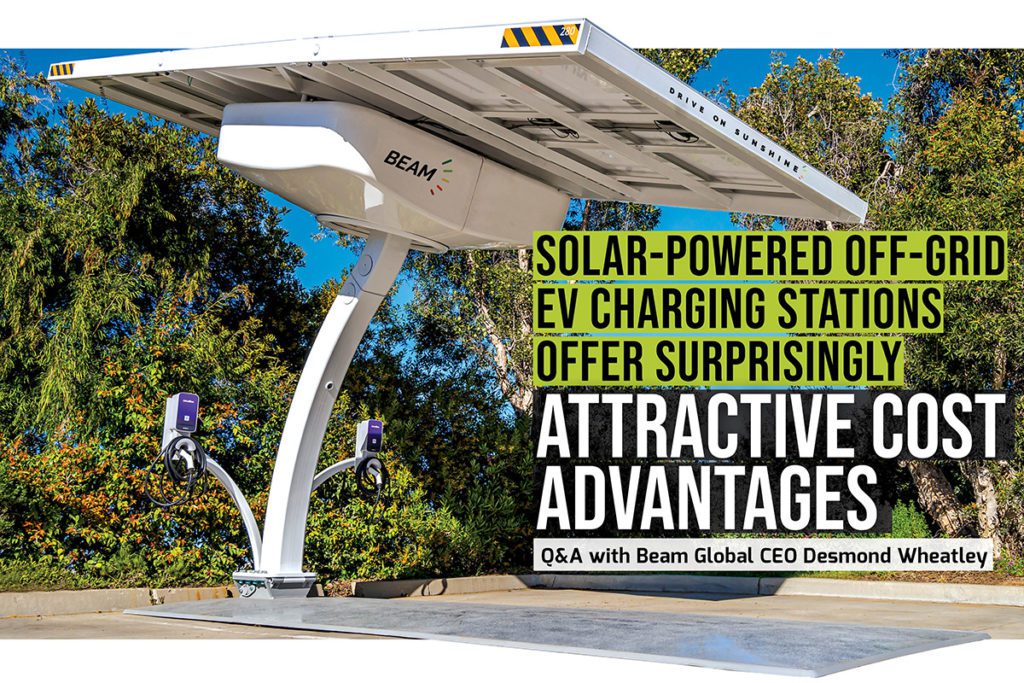

With the falling prices, increasing sales and growing mass-market appeal of plug-in vehicles, more and more facility owners are contemplating EV charging amenities for employees, tenants and visitors. EV infrastructure could become a real competitive differentiator by attracting the desirable EV-driving population. In today’s competitive landscape, facility owners can no longer ignore the idea of installing charging stations.

There are several considerations when installing EVSE, and affordability is at the top of the list. However, beyond the basic hardware, there are other factors that can dramatically affect the cost of an installation. For example, can the facility’s existing electrical infrastructure handle the increased electrical load brought on by EVSE?

Most commercial charging stations today are Level 2, and typically draw power from around 6 kW all the way up to around 18 kW. This year, DC fast charging options are beginning to become available in smaller, wall-mounted packaging at power levels starting around 20 kW.

The addition of EVSE could overload many electrical systems and significantly raise the cost of electricity with higher peak demand charges. If a property was built prior to the 1980s, the infrastructure could be outdated and unable to handle the new load without a complete retrofit – greatly increasing the project’s cost and scale, and negatively impacting your EVSE decision.

Lighten up

Fortunately, there are innovative solutions to this problem. “One of the most popular and cost-effective options is to reduce the overall electricity load of the facility before EVSE installation through a lighting upgrade,” Ken Sapp, VP of ABM’s Energy Solutions Group told Charged. ABM is a full-service EVSE and energy solution provider with a history of similar projects. The company claims some significant savings when implementing high-efficiency lighting and wireless lighting controls.

Sapp explains that lighting often represents the lion’s share of a facility’s energy consumption. “Up to 39 percent,” he said. Older facilities often have old fluorescent light fixtures and magnetic ballasts that house inefficient T12 or high-pressure sodium lamps. “Typically operating 24 hours a day, seven days a week, this outdated lighting scenario can really drain the grid, as well as make energy costs skyrocket,” he explains.

The potential energy savings of high-efficiency lighting can be enough to offset the implementation of EVSE without the need to rewire a facility’s existing electrical system. Also, by leveraging federal and local energy incentives, it’s possible to use creative low-interest financing with no large upfront cost.

Bright side of the bay

That was the case with a recent project that ABM completed for the city of Oakland, California. “They have one of the most ambitious energy efficiency efforts in the country, always looking to reduce overall energy use,” said Sapp. The city determined that parking facilities were among their biggest energy wasters, with most sporting old and obsolete lighting fixtures. It targeted one particular garage for a modern energy makeover, including EV charging stations to support sustainability efforts. However, the garage didn’t have the power capacity, and they wanted to complete the project without increasing the city’s operating budget.

So, ABM designed a total lighting makeover, complete with the latest in high-efficiency lighting and advanced controls. In the end, the project reduced energy use by 45%, and Oakland was able to pay for the entire project with its utility cost savings. “There was no upfront capital required,” explained Sapp, “and they were able to contribute a positive cash flow to the existing budget.”

You can do it too

The obvious first step to an efficiency upgrade is to swap out older light fixtures with state-of-the-art T8 lamps and high-efficiency lighting, and replace outdated ballasts with electronic ballasts that allow light levels to be programmed to dim during non-peak hours. There are several high-efficiency, low-maintenance lighting options available, including:

High-Intensity Discharge (HID) lamps

HID lamps use less power and are much brighter than most fluorescent and incandescent lamps. These are typically used when high levels of light over large areas are required, and when energy efficiency and light intensity are desired. HID bulbs are more fragile, have to warm up and are susceptible to aging and wear.

Light-Emitting Diodes (LEDs)

LED lamps don’t have filaments to burn out or break. Designed to have a 50,000-hour service life, they are very durable and require minimal maintenance. They are “instant on,” which makes them convenient for on-off cycling.

Induction

Induction lighting uses a light-generation technology that spreads light evenly over surfaces. Because it does not use traditional electrodes or filaments, there are no parts that wear out. Induction fixtures offer 5-10 times the life of HID lighting, and are designed to last an average of 100,000 hours.

Sapp explains, “These are all good high-efficiency lighting options, but each has advantages and disadvantages that must be considered carefully before being used in a lighting project.” He emphasizes the importance of contacting a professional lighting or energy solution consultant, such as ABM, to determine the best type of lighting. When efficiency is the goal, it’s critical to optimize results for each facility individually.

Taking control

While upgrading the lights will provide impressive energy improvements, Sapp says that this alone might not offload the circuit enough to support EVSE. To deepen the energy reduction potential and reduce peak electrical demand, Sapp explains that the new lighting needs to be paired with an advanced lighting control strategy that includes:

Wireless controls

Automated controls allow facility managers to pre-determine lighting system requirements based on area, peak and non-peak times, daylight, occupancy, or a combination of any of these factors. Facility managers can adjust the lighting system to behave differently for specific times of the day, week and holidays.

Occupancy detection

This feature senses when areas of a building are occupied and allows facility managers to light only occupied areas. Once a person has left the area, the lights turn off or dim after a pre-determined time period.

Daylight harvesting

Daylight harvesting leverages natural daylight to reduce the need for artificial light, yet still provides an even level of light in an area. Sensors recognize the difference between artificial and natural light, and when daylight is present ambient electric lighting is automatically reduced.

Bi-level tuning

This control device allows facility managers to establish different light levels by space type or area. It is especially good for stairwells and other dark places as lights can be set to dim but not go off and then brighten automatically when motion is detected.

Why wireless?

Sapp explains that wireless lighting controls offer functionality equivalent to, or better than, traditional wired controls systems, but at a lower cost and with easier installation. Wireless systems generally don’t require modifications or additions to existing wiring, and can be easily modified to adapt to changing space needs, schedules, or energy reduction strategies through reprogramming. “These systems provide a centralized, web-based dashboard for facility managers so they can track and monitor energy use and adjust controls in real time over the internet from any computer, anywhere,” he said.

All in all, Sapp says that the combination of upgraded lighting and wireless controls can reduce total lighting energy use by up to 50% – reducing peak loads and annual energy costs. “These gains in electrical capacity are significant enough to meet EVSE requirements, all while reducing utility costs. It is usually a quick and simple return on investment.”

This article originally appeared in Charged Issue 15 – August/September 2014