Electrical connectors are a critical component of EV technology, serving as the vital link between various systems that enable efficient energy transfer and communication. EVs rely on complex electrical architectures to power motors, charge batteries and support onboard electronics, and reliable connectors ensure seamless system integration. Their role goes beyond functionality. Connectors influence vehicle cost, safety, energy efficiency and overall performance. With the push for compact designs, faster charging and lower costs, innovative connector solutions have become indispensable in overcoming challenges in modern EV development.

Charged recently chatted with Stäubli’s connector experts David Rababy and Michael Domzalski to learn more about cutting-edge connection technologies.

For over 130 years, Stäubli has been at the forefront of industrial solutions, spanning diverse sectors like robotics, textiles, and connectors.

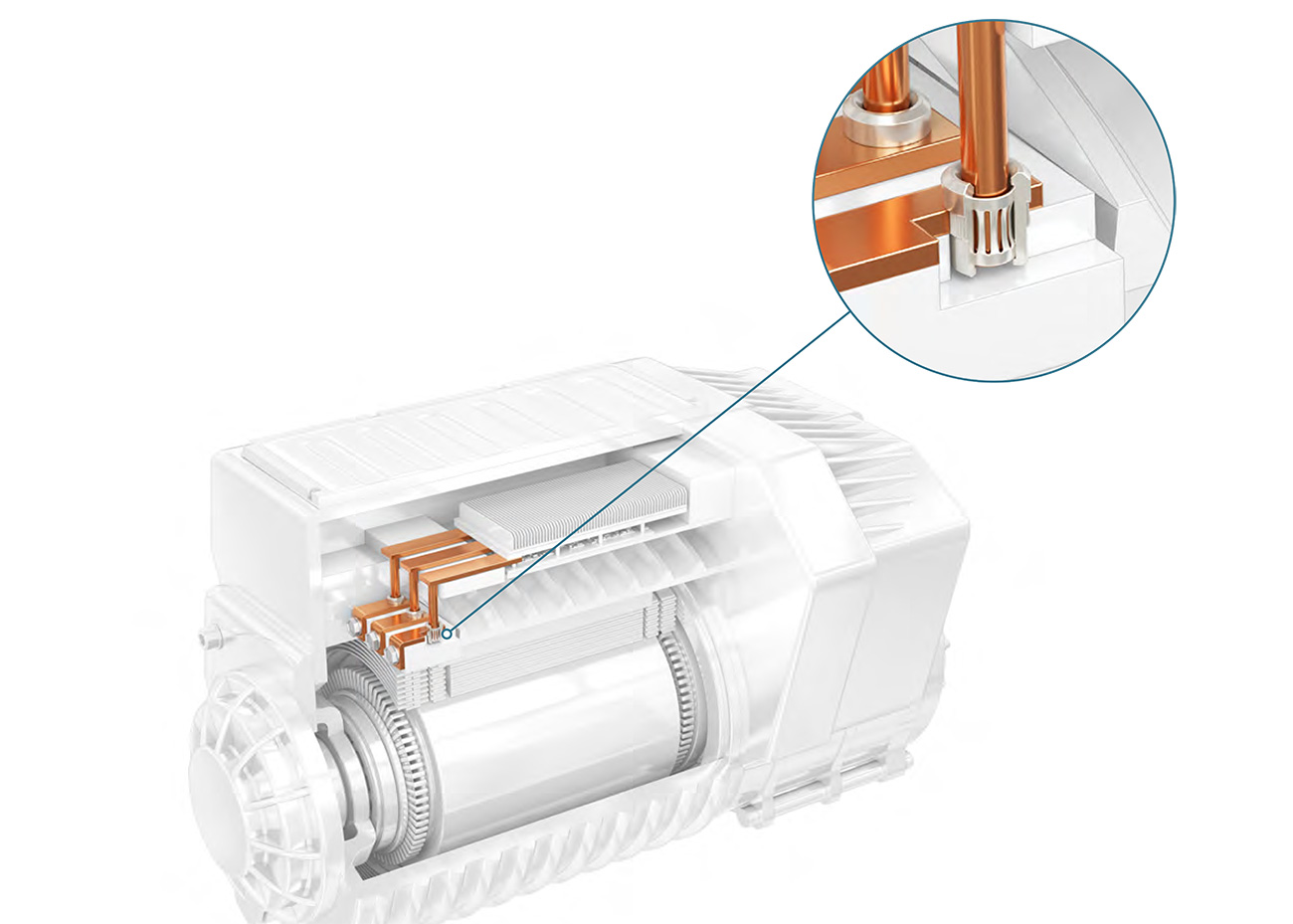

A standout new innovation from Stäubli is the ZeroBolt solution. As the name suggests, it’s designed to minimize the need for bolted connections. This plug-in system is ideal for applications with limited design space, such as electric motors, batteries and inverters. By eliminating bolted joints, manufacturers can save time during assembly and improve maintenance efficiency, making disassembly significantly easier. The solution also enhances durability by reducing the risks of loosening due to vibration, offering a robust alternative for high-performance designs.

Stäubli’s modular connector CombiTac system empowers manufacturers with customizable options. Whether for electrical signals, pneumatics, or fiber optics, these connectors can be configured quickly using Stäubli’s online configurator. Designed for high mating cycles and robust industrial use, these systems excel in both prototyping and mass production.

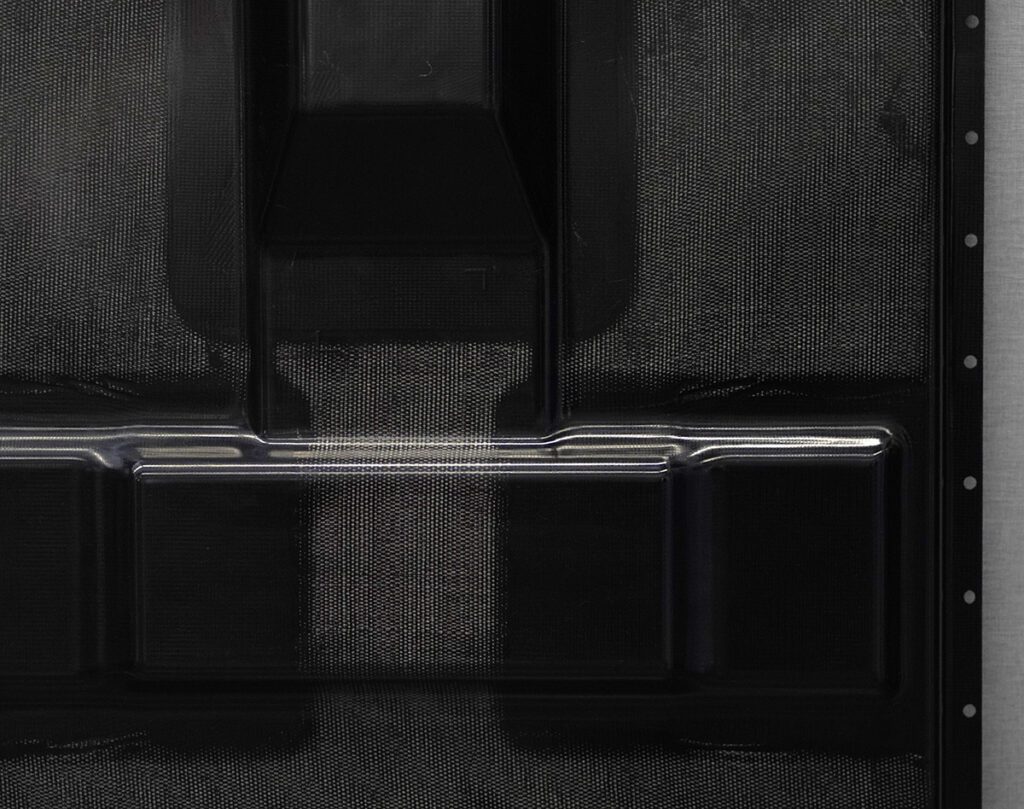

Stäubli is also a leader in high-power connectors, like the Megawatt Charging System (MCS) that pushes the boundaries of EV charging technology, achieving faster, more efficient energy transfer for trucking, off-highway, and heavy-duty applications.

Additionally, Stäubli is exploring solutions to support the growing demand for lightweight and cost-effective materials, such as aluminum in busbars, which can reduce weight and expense in electric vehicles. Another area of innovation focuses on integrated cooling systems for onboard applications, addressing challenges like heat management and space optimization.

For more information about new connector technologies, visit: https://www.staubli.com/