Fires caused by thermal runaway continue to be a significant issue in the evolution of EV battery packs. Now, as the EV marketplace approaches a tipping point, engineers are racing to address this challenge using various technologies. These include high-performance, pressure-sensitive adhesives (PSA) used in combination with thermal materials that can assist in hindering thermal runaway propagation.

Join this session at next week’s Virtual Conference on EV Engineering where a team of experts—including Michael VanHaerents (Avery Dennison Performance Tapes), Michael Sanders (Avicenne Energy) and Melissa Widener (Alkegen)—will share their insights and explain how and why PSAs are being incorporated into thermal runaway prevention barriers. These adhesives offer multiple advantages for EV batteries, including flame retardancy, ease of assembly, corrosion prevention, and end-of-life recyclability.

Other sessions at our Spring Virtual Conference include:

Electrode Slurry Mixing: Harnessing Sub-Second Powder Dispersion

Mixing with incumbent technologies like planetary mixers is unsustainable as demand outstrips current mixing productivities. The Batt-TDS is a next-generation mixing system for high-viscosity slurries that is poised to replace all Production electrode slurry mixing for EVs. Dispersion of powders can be accomplished in tens of milliseconds. An R&D batch is fully mixed within a few minutes, self-lubricated in continuous stream of liquids. With systems up to greater than 5000 L/hour, the system is ready for today and tomorrow’s gigafactories.

Register here to learn more—it’s free!

How To Achieve Conformance To Standards For Electric Vehicle Charging Systems

In this presentation, dSPACE and KPIT will explain the main difference between testing a standard vehicle electronic control unit (ECU) versus an electric vehicle communication controller. A test environment will be introduced and used for executing a test for all relevant charging standards, such as CCS, GB/T and CHAdeMO.

Additionally, testers will learn how they can benefit from integrating their existing software and tools with dSPACE solutions and KPIT engineering to achieve an ideal environment for development and testing.

Register here to learn more—it’s free!

Critical Connections For EV Charging: Correctly Specifying Liquid Cooling Fluid Connectors

With fast- and extreme-fast EV charging, system manufacturers are quickly learning how and where to implement liquid cooling to keep powerful electronics components from overheating, failing, or causing damage. What is not broadly understood is which structural or performance characteristics of quick disconnect (QD) couplings need to be taken into account when spec’ing them into a liquid cooling system. A range of QD solutions are available and perfectly suited for these systems but flow, compatibility, and composition — along with location within a cooling system — must be understood in order to achieve reliable and optimal charging.

Using actual (but anonymized) customer projects, this session will cover multiple EV liquid cooling scenarios and the design and decision-making process that went into the quick disconnect selection based upon each’s unique space constraints, timeframe, coolant, and/or budget.

The session will also cover:

- What termination options are typically available and which are ideally suited for EV charging cooling

- Why purpose-built for liquid cooling connectors are superior for keeping umbilicals, station/pile electronics and batteries cool

Register here to learn more—it’s free!

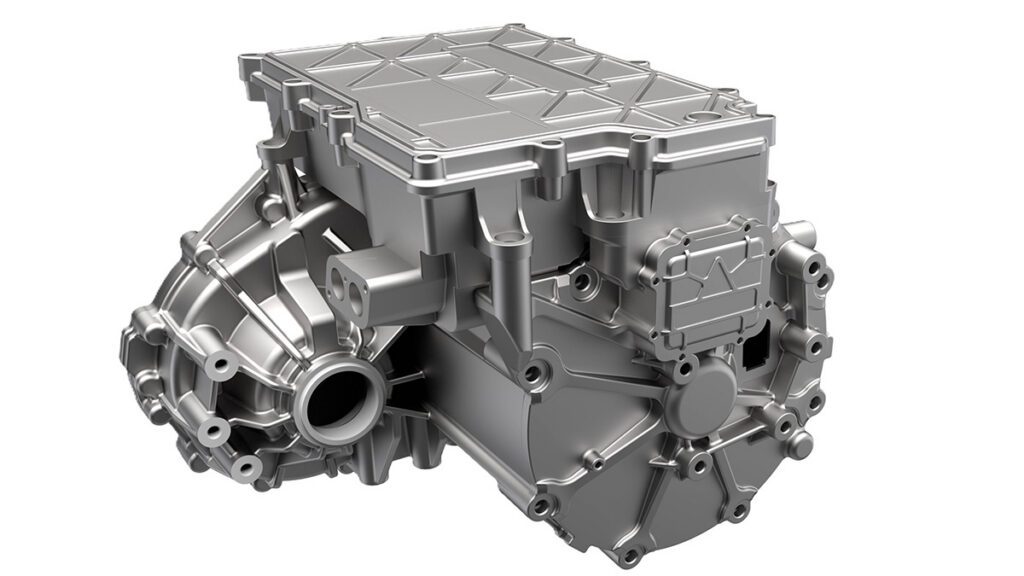

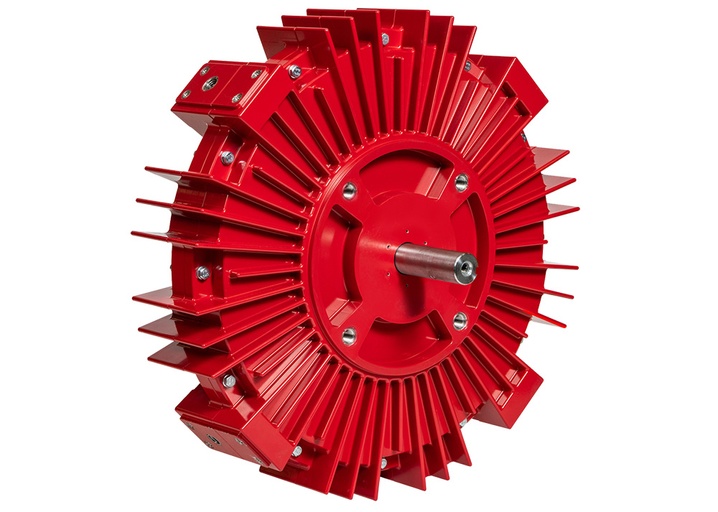

How To Gain Flexibility And Speed In Prototyping And Manufacturing EV Motors

As automotive OEs and suppliers are being driven to innovate faster by consumers demanding more in terms of range and overall experience, Infinitum Electric motors are here to help.

In this session, we’ll discuss how Infinitum Electric’s approach to PCB motor technology provides advantages in areas such as oil cooling and in simplifying the manufacturing process so automotive companies can quickly iterate and reduce time to market.

Register here to learn more—it’s free!

See the full sessions list for the Spring Virtual Conference on EV Engineering here.

Broadcast live April 4 – 7, 2022, the conference content will span the EV engineering supply chain and ecosystem including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.